Compound movement type artificial hip joint frictional wear experiment equipment

A composite motion, friction and wear technology, applied in the direction of testing wear resistance, can solve problems such as deficiencies, and achieve the effects of convenient control, simple structure, stable and flexible loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

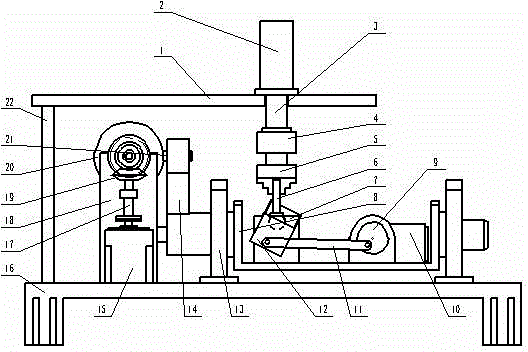

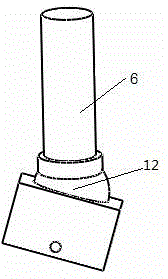

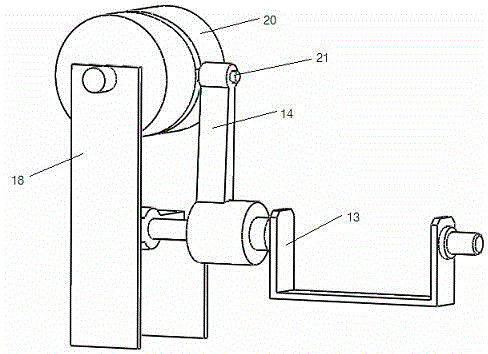

[0016] Such as figure 1 As shown, the compound kinematic artificial hip joint friction and wear test device of the present invention includes a frame, a loading device and a compound kinematic mechanism. The frame includes an upper top plate 1, a column 22, a swing table support seat 13, a cylindrical cam support seat 18 and a base 16; the loading device includes a hydraulic cylinder 2 for loading pressure, a main shaft 3 for transmitting loading force, and a three-grip chuck 5 And femoral head style 6; the hydraulic cylinder 2 is fixed by the upper top plate 1, and the upper top plate 1 and the hydraulic cylinder 2 are fixed by the column 22 and the base 16; the compound motion mechanism includes a swing mechanism that realizes swinging back and forth And realize the rotation mechanism of left and right rotation, described swing mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com