Combined control cable and preparation method therefor

A control cable, combined technology, used in cable/conductor manufacturing, insulated cables, communication cables, etc., can solve the problems of inability to meet performance requirements, single main performance of the cable, etc., to prevent corrosion, good water resistance, and improved resistance The effect of pulling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

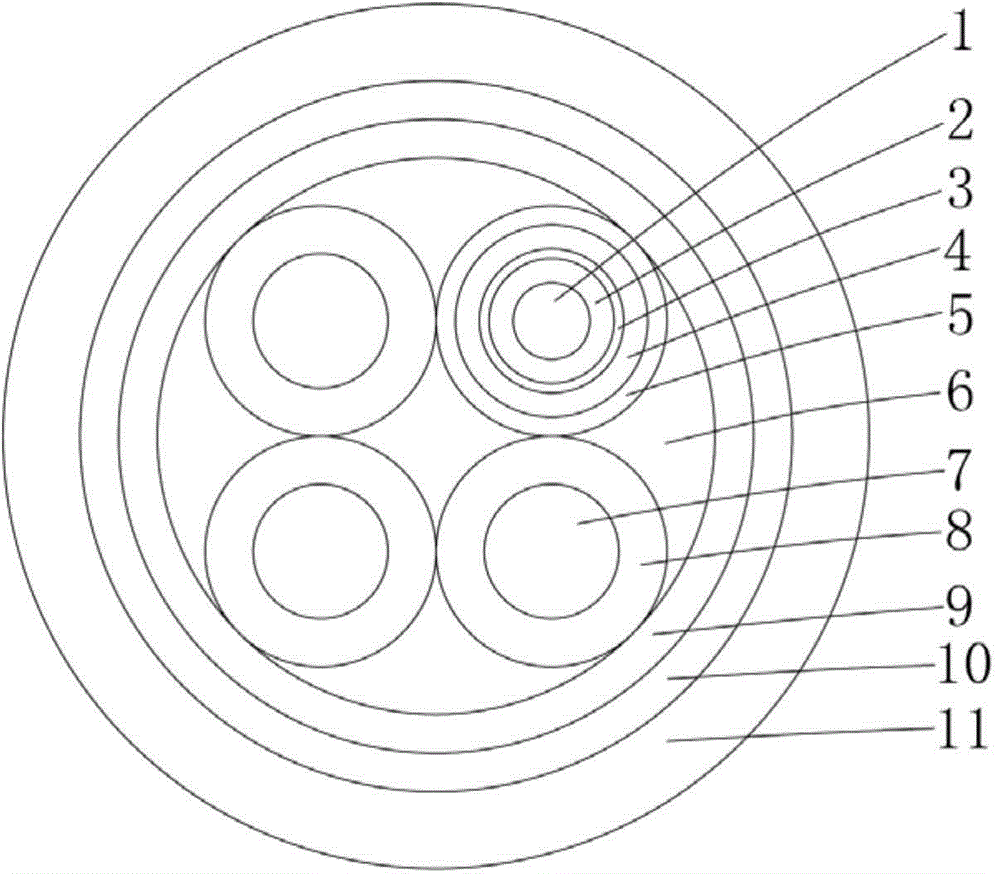

[0029] Example: Combine figure 1 , the combined control cable of this embodiment:

[0030] The cable core of the control cable is composed of an optical cable and a plurality of insulated control wire cores stranded, wherein the optical cable includes an optical fiber 1, a primary coating layer 2, a secondary coating layer 3, a braided reinforcement layer 4 and A polyolefin sheath layer 5 extruded on the braided reinforcing layer;

[0031] The three insulated control wire cores are each composed of a tinned annealed copper conductor 7 and a polyolefin insulation layer 8; a filling layer 6 is provided in the twisting gap between the optical cable and the insulated control wire core, and a wrapping layer is sequentially wrapped outside the cable core and the filling layer. The belt layer 9 is braided with tinned copper wire shielding layer 10 and extruded with polyolefin outer sheath 11 .

[0032] In a specific implementation, the braided reinforcement layer 4 is braided by ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com