Brushless DC motor for soybean milk machine

A brushless DC motor, soybean milk maker technology, applied in the field of motor design, can solve the problems of reduced motor efficiency, secondary pollution of food machinery, loud noise and dust, etc., to improve efficiency and life, compact and practical motor structure, eliminate noise and effect of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the drawings.

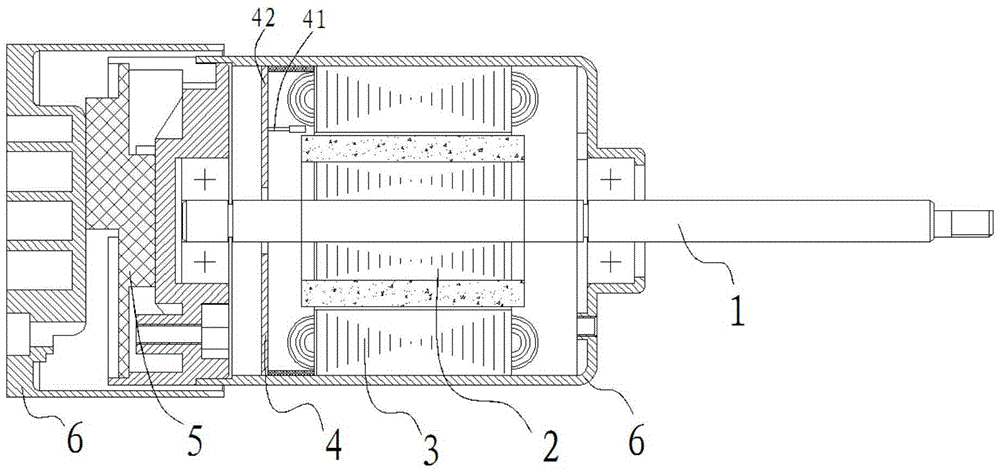

[0016] reference figure 1 — Figure 4 , Brushless DC motor for soybean milk machine, including main shaft 1, rotor 2, stator 3, Hall structure 4, driver 5 and machine case 6. One end of the main shaft 1 is fixed in the casing 6 with a bearing, and the other end can be connected to various household soymilk machines.

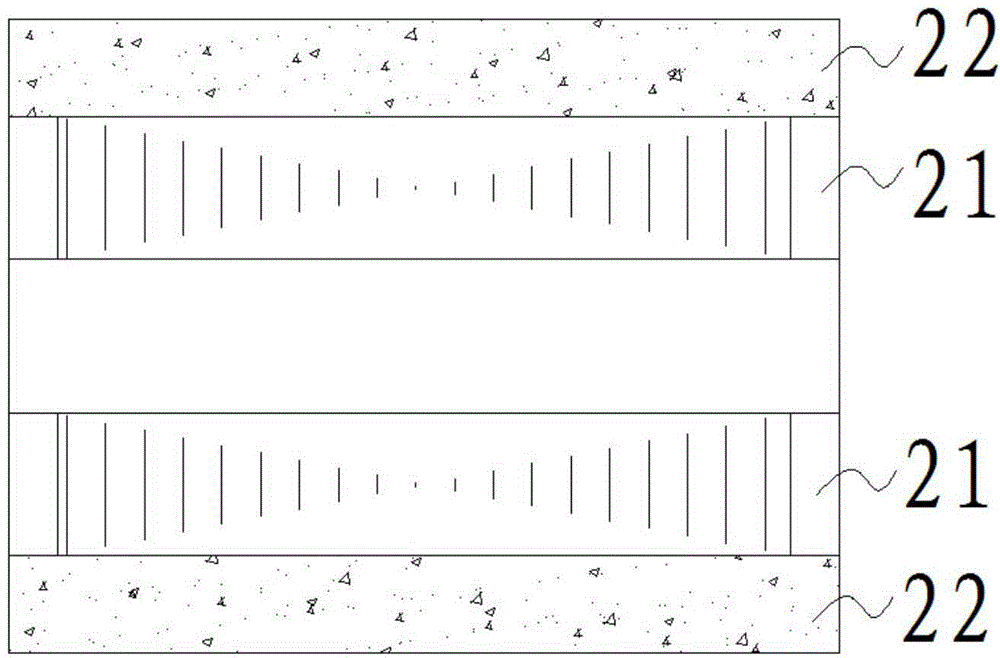

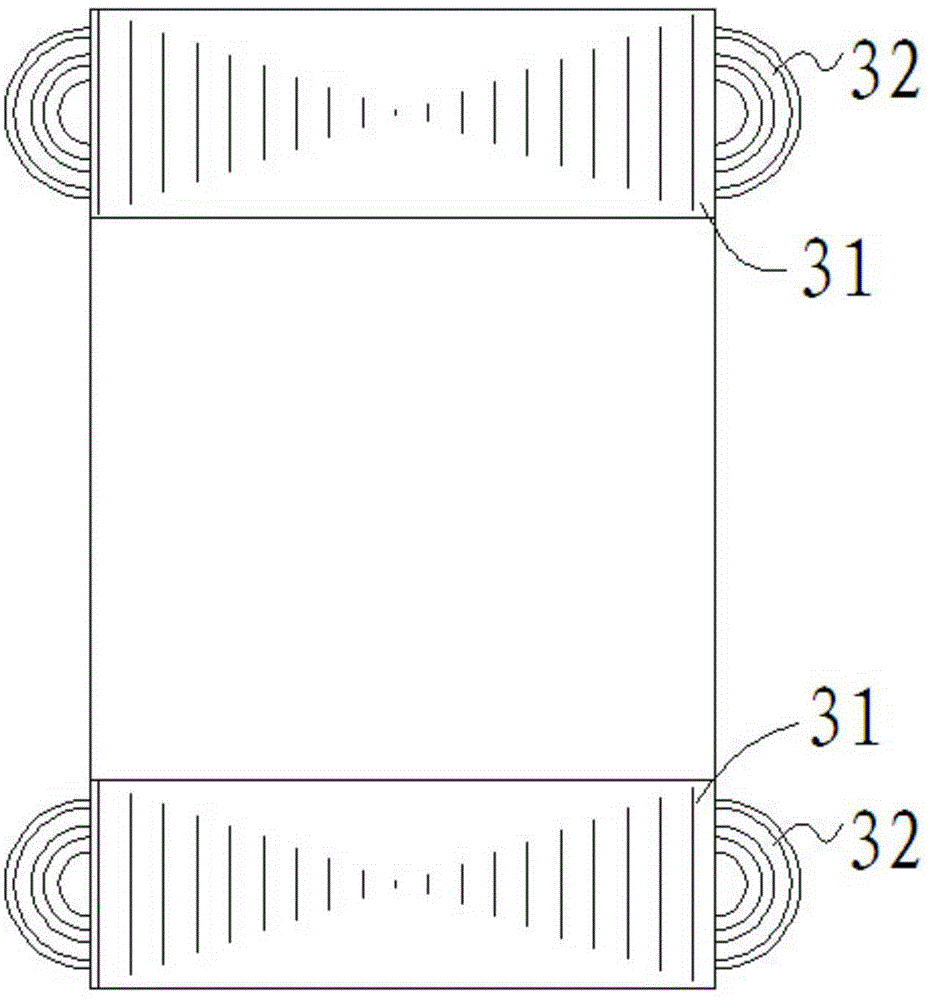

[0017] The rotor 2 is installed on the main shaft 1, and the stator 3 is installed near the inner surface of the casing 6 and close to the rotor 2, so that the rotor 2 can be within the influence range of the magnetic field generated by the stator 3 during operation. The Hall structure 4 includes a Hall sensor 41 and a Hall plate 42, wherein the Hall sensor 41 is installed on the Hall plate 42, the Hall plate 42 is fixed in the casing 6, and the Hall sensor 41 is installed at a distance from the rotor 2. 1~2mm of the permanent magnet 22. The driver 5 is contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com