Single screw extruder

A single-screw extrusion and spiral cone technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of insufficient extrusion tearing force, poor tearing effect, etc., to achieve resistance to wear, enhanced toughness, and high hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

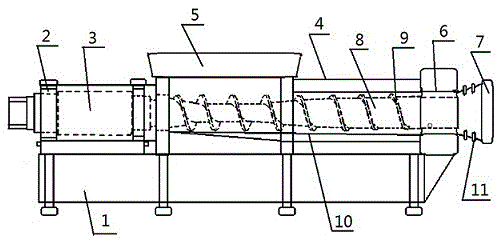

[0022] Depend on figure 1 It can be seen that the single-screw extruder of the present invention comprises a frame 1, a bearing chamber 2, and a closed cover 4, the bearing chamber 2 is fixed on the left side of the frame 1, and the bearing chamber 2 is movably equipped with a transition shaft 3; The closed cover 4 is fixed on the right side of the frame 1, the upper left side of the closed cover 4 is provided with a feed inlet 5, the right side of the closed cover 4 is provided with a discharge cover 6, and the discharge cover 6 is fixedly connected to the discharge port 7; A spiral cone shaft 8 is also installed in the closure cover 4 described above, one end of the spiral cone shaft 8 passes through the left side of the closure cover 4 and is connected with the transition shaft 3 shaft head insert sleeve, and the other end of the spiral cone shaft 8 is installed on the discharge side of the discharge side. The material sleeve 6 is connected with the movable cantilever of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com