Antifog sheet

An anti-fog sheet and sheet-layer technology, applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of high production cost, low temperature resistance, easy oxidation, etc., and achieve low production cost, non-scratch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

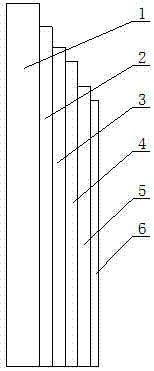

[0008] like figure 1 As shown, an anti-fog sheet includes a substrate layer 1, a metal plastic sheet layer 2, reflective particles 3, a decorative film 4, a matte film 5, and a silicone oil layer 6. The substrate layer 1 is made of PBT material and PET material. phase blending and adding catalysts, flame retardants and antioxidants, the surface of the substrate layer 1 is sequentially provided with a metal plastic sheet layer 2, reflective particles 3, decorative film 4, matting film 5 and silicone oil layer 6 , the silicone oil layer 6 is completed by a silicone oil spraying system arranged above the coiling device. The substrate layer 1 of the present invention is made by blending PBT materials and PET materials and adding catalysts, flame retardants, and antioxidants. The product has the advantages of rapid crystallization, flame retardancy, high temperature resistance, and oxidation resistance, while reducing production costs. Cost, in the production process, the silicone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com