Packing gasket for protecting liquid crystal display panel semi-finished product

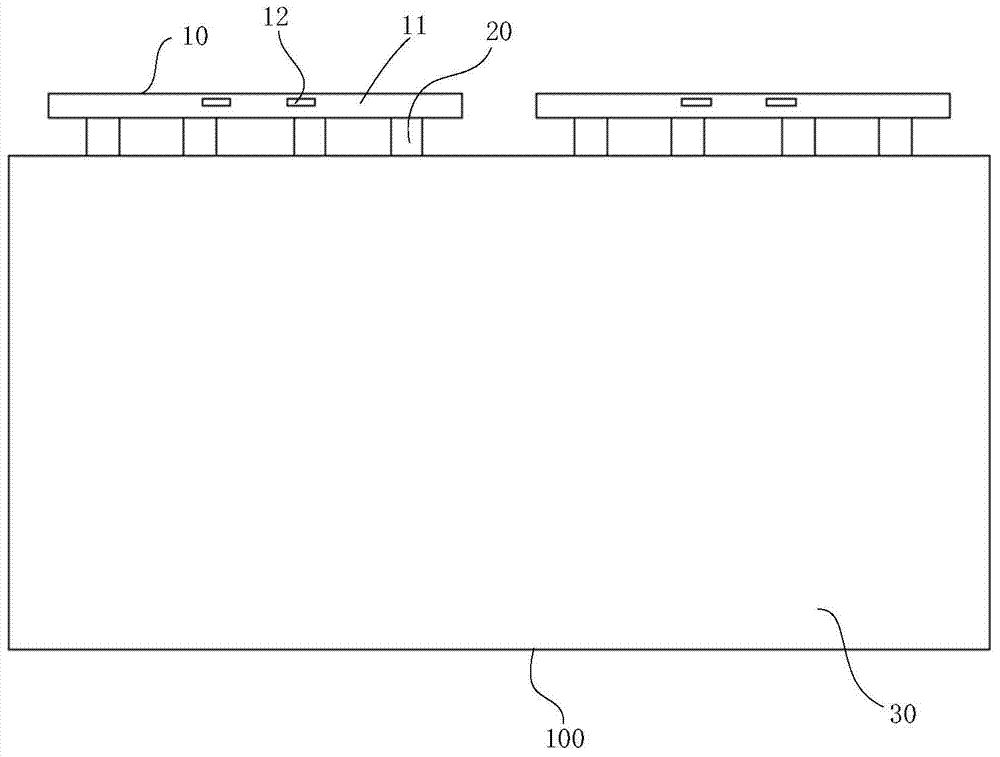

A technology for liquid crystal panels and semi-finished products is applied in the field of packaging gaskets for protecting semi-finished liquid crystal panels, and can solve problems such as upward protrusion and inclination of printed circuit board components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

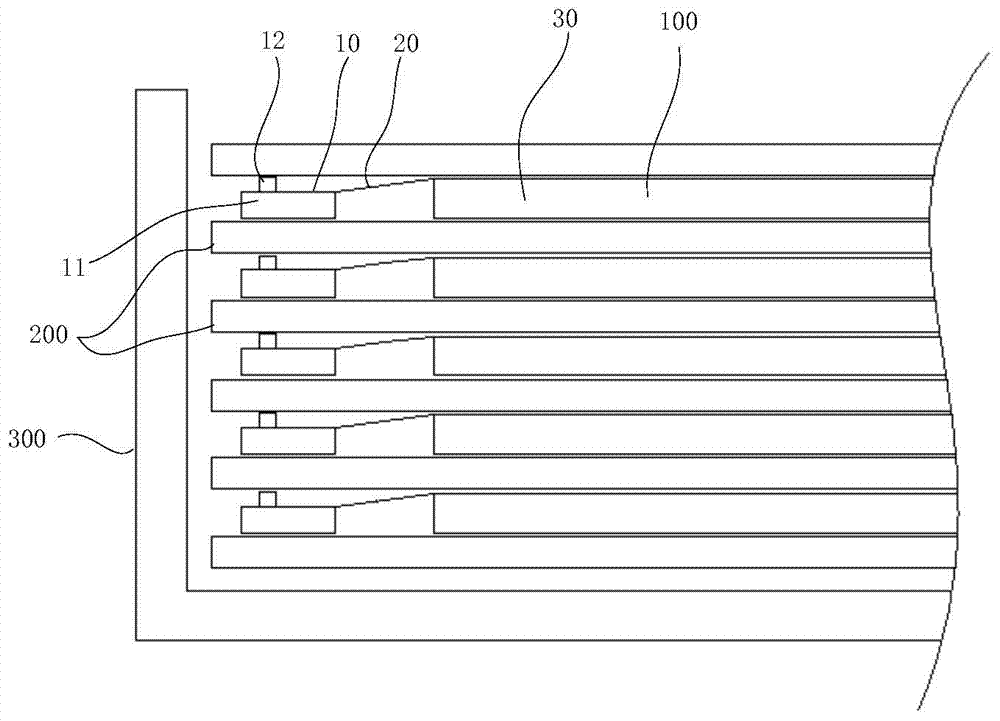

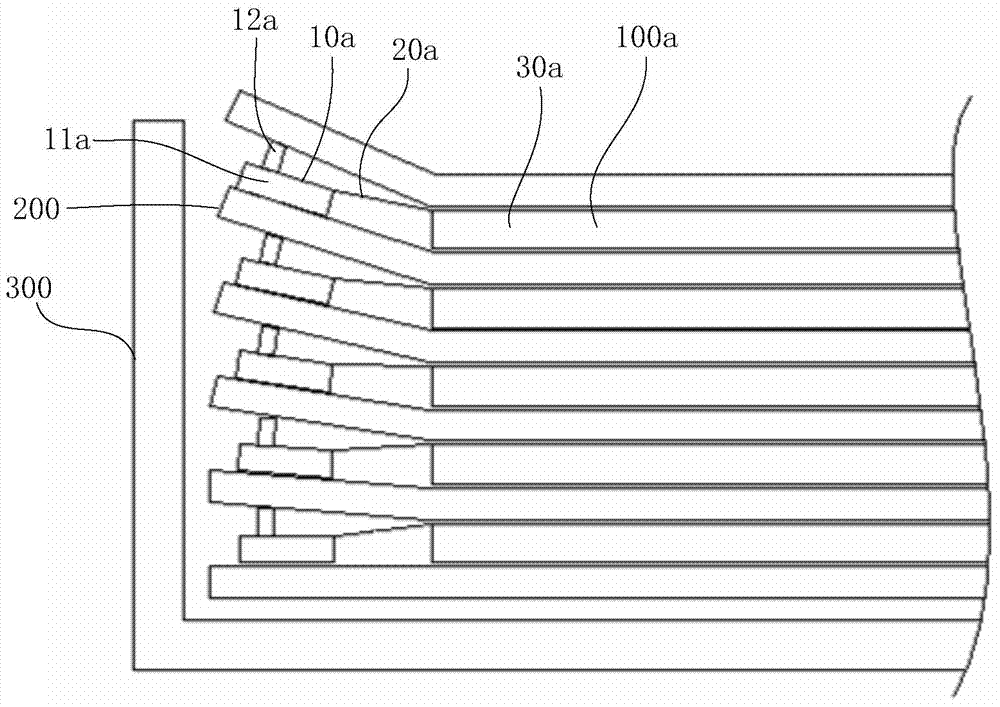

[0025] The present invention will be further described below in conjunction with accompanying drawing.

[0026] Figure 4 A packing gasket 400 of a first embodiment of the present invention is shown. The packaging gasket 400 includes a first partition 401 and a second partition 402 . The first partition 401 has a thin plate shape. The first partition 401 includes a first plate surface 403 and a second plate surface 404 opposite to the first plate surface 403 . The first plate surface 403 is parallel to the second plate surface 404 . The first plate surface 403 and the second plate surface 404 of the first partition 401 can abut against the liquid crystal screens 30a of two adjacent liquid crystal panel semi-finished products 100a respectively to separate the liquid crystal screens 30a of two adjacent liquid crystal panel semi-finished products 100a. The first partition 401 is configured as a square plate, which can match the shape of the liquid crystal panel 30 a to reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com