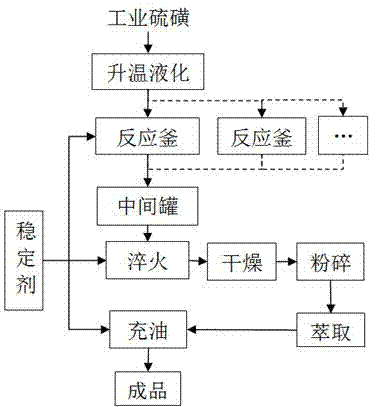

Production process for preparing insoluble sulphur through low temperature method

A production process and technology of low temperature method, which is applied in the field of production technology for preparing insoluble sulfur by low temperature method, can solve the problems of insoluble sulfur energy consumption, high equipment requirements, and low safety, and achieve simple production equipment and process, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Pour 1 kg of ordinary industrial sulfur with a content of 99.9% into a high-level sulfur melting tank and raise the temperature to 150°C to liquefy, and use the high-level difference to mix the liquid sulfur and the composite stabilizer (composition: 0.5gI 2 +2.5gDZ) into the stirred reactor, polymerize at 250°C for 35 minutes, flow the molten sulfur into the intermediate tank through the discharge valve, spray it into the quenching liquid through the nozzle, and control the temperature of the quenching liquid at 10°C , add 0.01% composite stabilizer to the quenching liquid. Dried at 60°C for 10 hours, crushed to more than 200 mesh, extracted with carbon disulfide at 20°C; dried the extracted insoluble sulfur at 60°C for 5 hours, added 0.05% composite stabilizer, extended oil with high thermal stability Insoluble sulfur. Analysis of its thermal stability is 50.4% at 120℃╳15min, and the content of insoluble sulfur is 98.3%.

Embodiment 2

[0027] Pour 1kg of ordinary industrial sulfur with a content of 99.9% into a high-level sulfur melting tank and heat it up to 150°C to liquefy, and use the high-level difference to add liquid sulfur and composite stabilizer (composition: 0.3gKI+1.5gDM) into the reactor with stirring. Polymerize at 260°C for 30 minutes, pour the molten sulfur into the intermediate tank through the discharge valve, spray it into the quenching liquid through the nozzle, control the temperature of the quenching liquid at 12°C, and add 0.02% composite stabilizer to the quenching liquid . Dried at 65°C for 12 hours, crushed to more than 200 mesh, extracted with carbon disulfide at 40°C; dried the extracted insoluble sulfur at 70°C for 3 hours, added 0.08% composite stabilizer, oil-extended with high thermal stability Insoluble sulfur. Analysis of its thermal stability is 51.5% at 120℃╳15min, and the content of insoluble sulfur is 98.7%.

Embodiment 3

[0029] Pour 1kg of ordinary industrial sulfur with a content of 99.9% into a high-level sulfur melting tank and heat it up to 150°C to liquefy, and use the high-level difference to mix the liquid sulfur and the composite stabilizer (composition: 1.0gI 2 +1.5gDZ) into the stirred reactor, polymerize at 250°C for 35 minutes, flow the molten sulfur into the intermediate tank through the discharge valve, spray it into the quenching liquid through the nozzle, and control the temperature of the quenching liquid at 8°C , add 0.05% composite stabilizer to the quenching liquid. Dried at 70°C for 13 hours, crushed to more than 200 mesh, extracted with carbon disulfide at 30°C; dried the extracted insoluble sulfur at 40°C for 12 hours, added 0.03% composite stabilizer, oil-extended with high thermal stability Insoluble sulfur. Its thermal stability is 48.1% at 120℃╳15min, and the content of insoluble sulfur is 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com