Ridge assembled roof bent frame

An assembled and bent-frame technology, which is applied to roofs, building components, buildings, etc., can solve the problems of wasting roof space, high cost, long and heavy triangular roof trusses, etc., and achieves convenient maintenance, low construction and installation costs, and convenient transportation and assembly. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

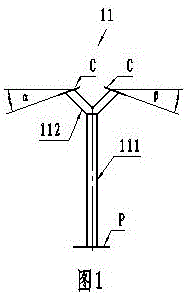

[0017] Figure 1 to Figure 8 A ridge-assembled roof bent frame is shown, which includes a roof middle bent frame 1 and an array of different height roof front slope bent frames 2 i , an array of roof back slope bent frames of different heights 3 j , several connecting fasteners 4; it is characterized in that: the roof intermediate bent frame 1 includes several roof intermediate bent frame pillars 11, several purlins L, several purlin connecting plates T, several purlins Fastener J, the length of which is equal to the length of the floor; the middle bent frame pillar 11 of the roof, which includes a central column 111, a V-shaped double-slope joint 112, a connecting plate P at the end of the pillar plane, and an inclined-plane end of the pillar The connecting plate C; the V-shaped double-slope joint 112 is respectively connected and fixed with the connecting plate C at the end of the inclined plane of the pillar, and the other end is connected and fixed with one end of the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com