Secondary recovery method for stagnant ore blocks

A secondary recovery and sluggish technology, applied in the direction of mining fluid, earth drilling, wellbore/well components, etc., can solve the problems of the underground dissolution cavity losing the sealing condition, the inability to perform brine extraction by water lifting, and the reduction of brine extraction capacity. Achieve the effects of reducing energy consumption, alleviating the shortage of brine sources for salt making, and restoring normal production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

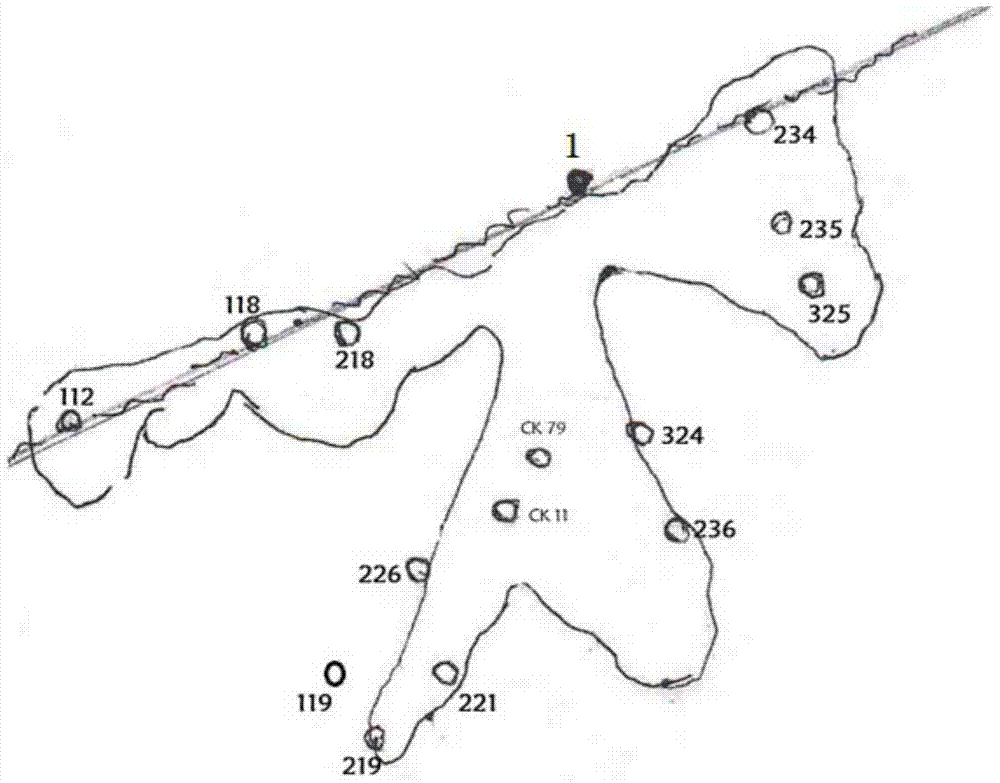

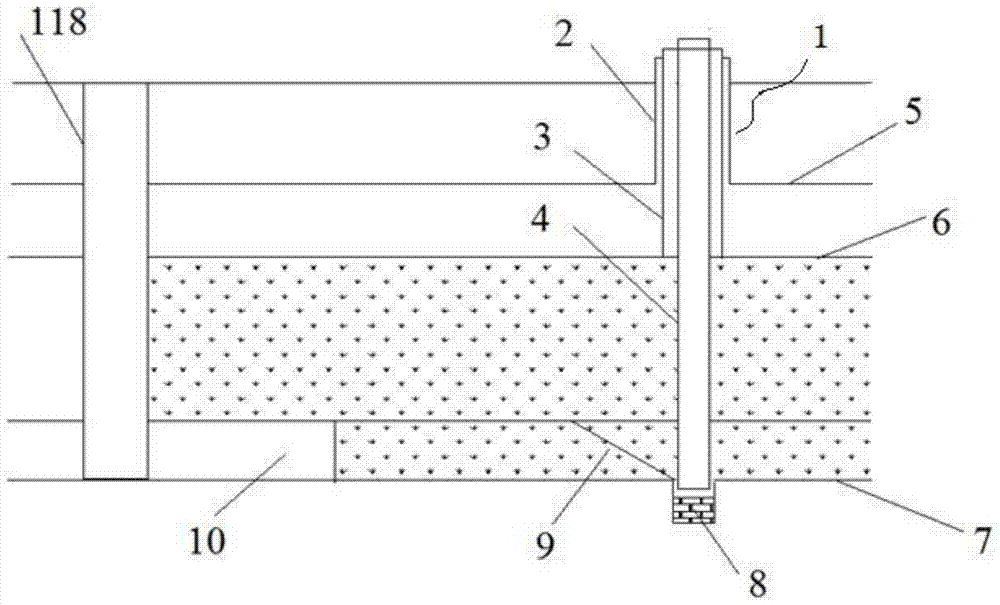

[0033] figure 1 It is a schematic diagram of the location of the new well in the embodiment of the present invention, figure 2 It is a schematic diagram of the structure of the new well body and its relationship with the waste dissolution chamber in the embodiment of the present invention.

[0034] like figure 1 As shown, it is a schematic diagram of the location of the new well in the embodiment of the present invention. The dogleg stope is composed of twelve wells. The horizontal projection of the underground dissolution cavity is in the shape of an inverted mountain. The overburden layer on the ore body is 237.6-387.42 meters thick, and the incipient solution layer is buried at a depth of 272.5-341.8 meters. The or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com