A buffer suspension flow regulating device

A flow regulating device and flow regulating technology, applied in the field of sanitary ware, can solve problems such as inability to regulate flow, unbalanced pressure, small operating force, etc., achieve precise flow regulation, avoid frontal impact, and save labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

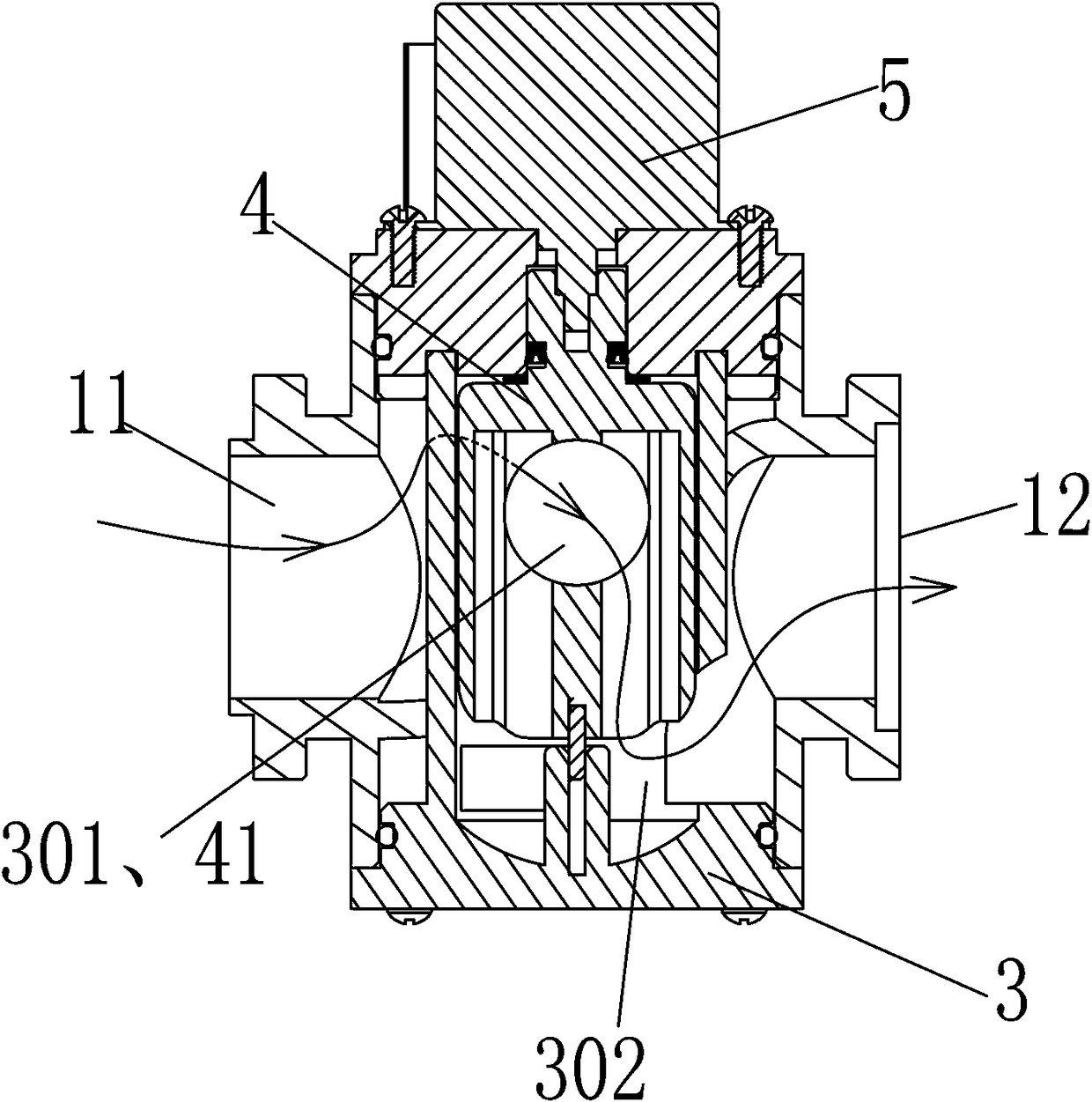

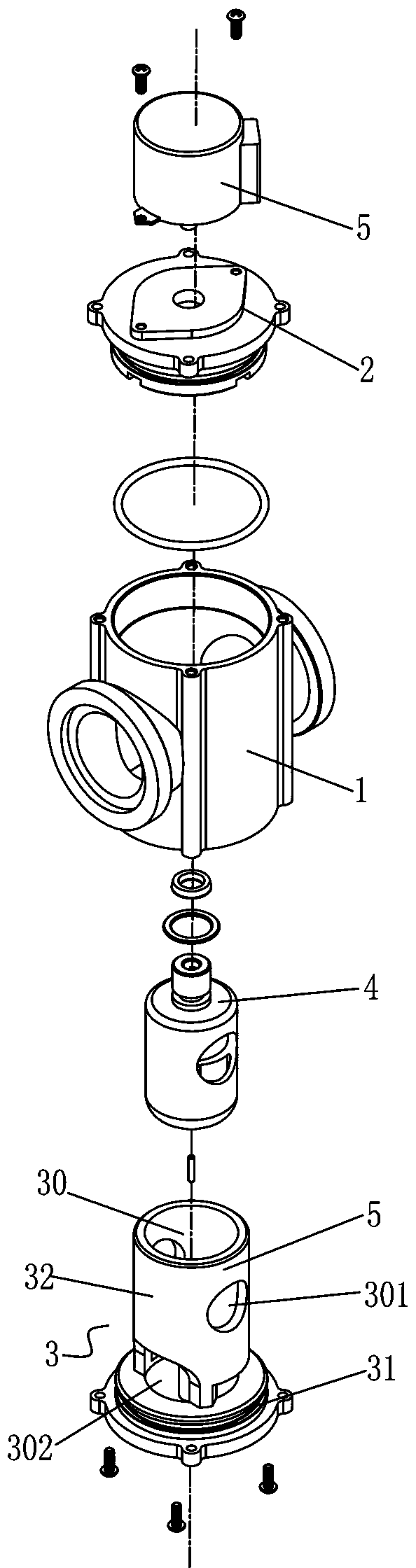

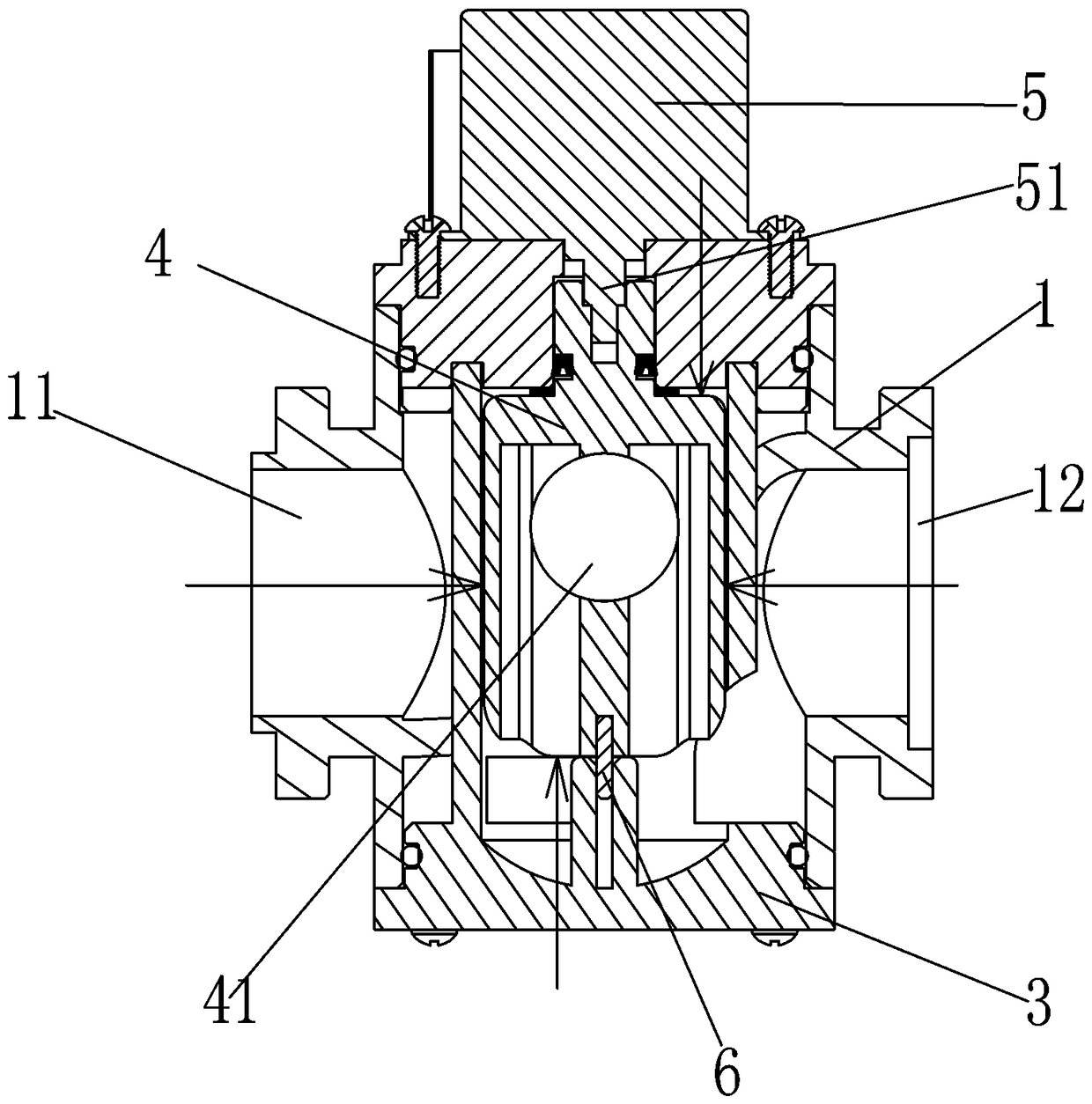

[0038] Specific implementation methods, such as Figure 1 to Figure 4 As shown, the buffer suspension flow regulating device described in the present invention mainly includes the following components: body 1, cover body 2, base 3, water control unit 4 and motor 5;

[0039] When assembling, first, a shaft body 6 is installed at the bottom of the water control unit 4, and the water control unit 4 equipped with the shaft body 6 is placed in the buffer chamber 30 on the base 3, and the shaft body 6 is attached to the base body 31, so that the water control unit 4 can be rotated and fitted in the buffer cavity 30, and through its rotation, the flow regulating hole 41 of the water control unit 4 is superimposed or dislocated with the water passing area of the water inlet hole 301 on the base 3; Not only that, a certain gap is formed between the water control unit 4 and the interior of the buffer chamber 30, so that the water flow covers the entire water control unit 4;

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com