Cyclone incinerator

A technology of incineration device and swirling flow, which is applied to incinerators, combustion methods, combustion types, etc., can solve the problems of difficult to achieve fluidization, increase the resistance of the air distribution plate, and the materials are easy to accumulate at the bottom, so as to avoid accumulation and non-fluidization. , to ensure stable combustion and enhance the effect of disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

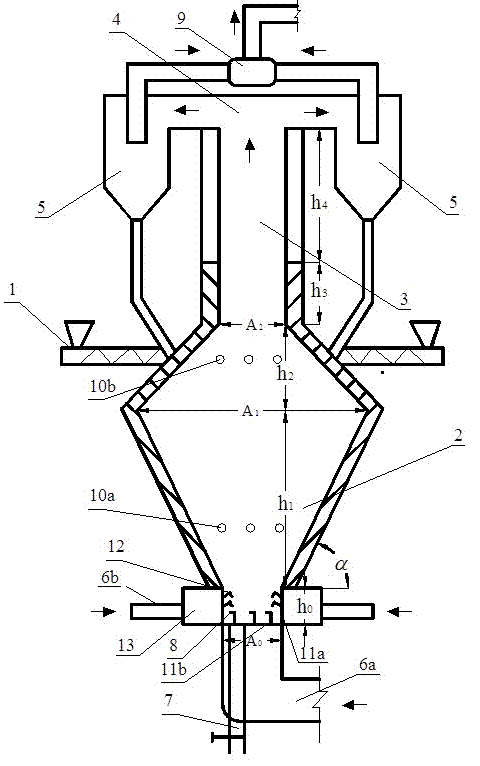

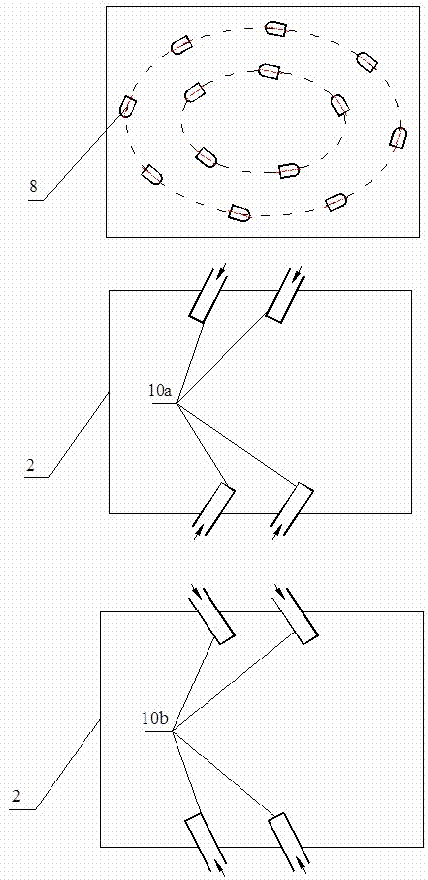

[0012] like figure 1 As shown, a cyclone incineration device includes a symmetrically arranged feeding device 1, a furnace 2, a cyclone separator 5, and the like. The top of the furnace 2 is connected to the vertical flue 3, and the top of the vertical flue 3 is arranged with an overhead flue 4, and the cyclone separator 5 is connected to the overhead flue 4, and the two sides are arranged symmetrically. Furnace 2 is wide in the middle and narrow at the upper and lower sides, and the cross-sectional area of the bottom is A 0 Minimum, cross-sectional area A of the minimum upper part 2 >A 0 , the cross-sectional area A at the widest point in the middle 1 is the bottom cross-sectional area A 0 2 to 4 times that of the furnace, so as to ensure that the furnace 2 has enough internal rotation space, and reduce material elutriation.

[0013] The inner wall of the furnace 2 is covered with refractory materials, and the height of the section from the air distribution plate 11 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com