Rolling bearing fault diagnosis method based on composite multi-scale permutation entropies

A technology for fault diagnosis and rolling bearings, applied in mechanical bearing testing, measuring devices, instruments, etc., can solve problems such as large deviations in permutation entropy values, achieve high classification efficiency, reduce dimensionality, and fast training speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

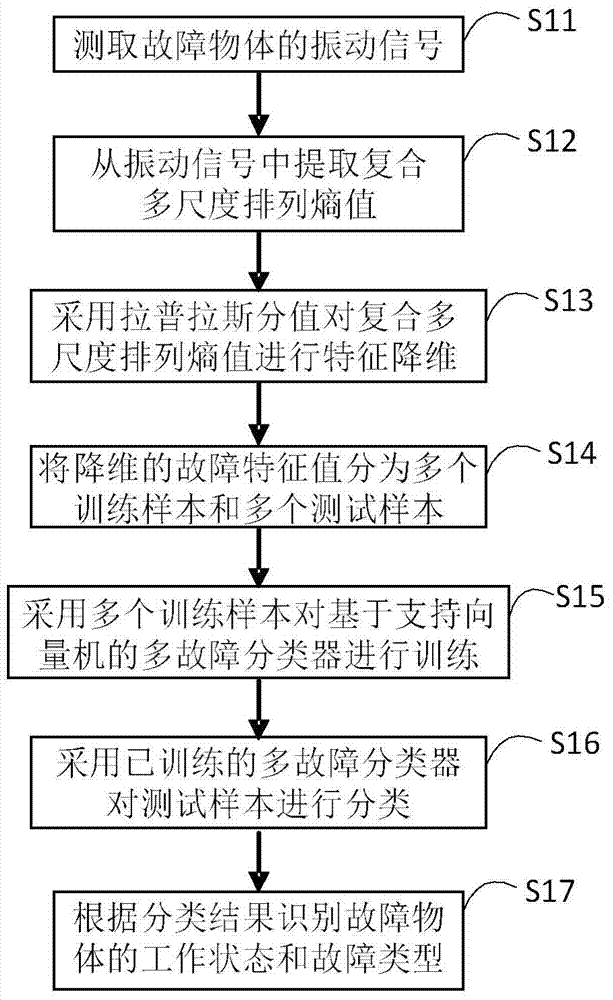

[0063] see figure 1 In this embodiment, the rolling bearing diagnosis method based on compound multi-scale permutation entropy, Laplacian score and support vector machine includes the following steps:

[0064] Step S11, measuring the vibration signal of the faulty object. For example, the acceleration sensor can be used to measure the vibration of the rolling bearing supporting seat to obtain the vibration acceleration signal.

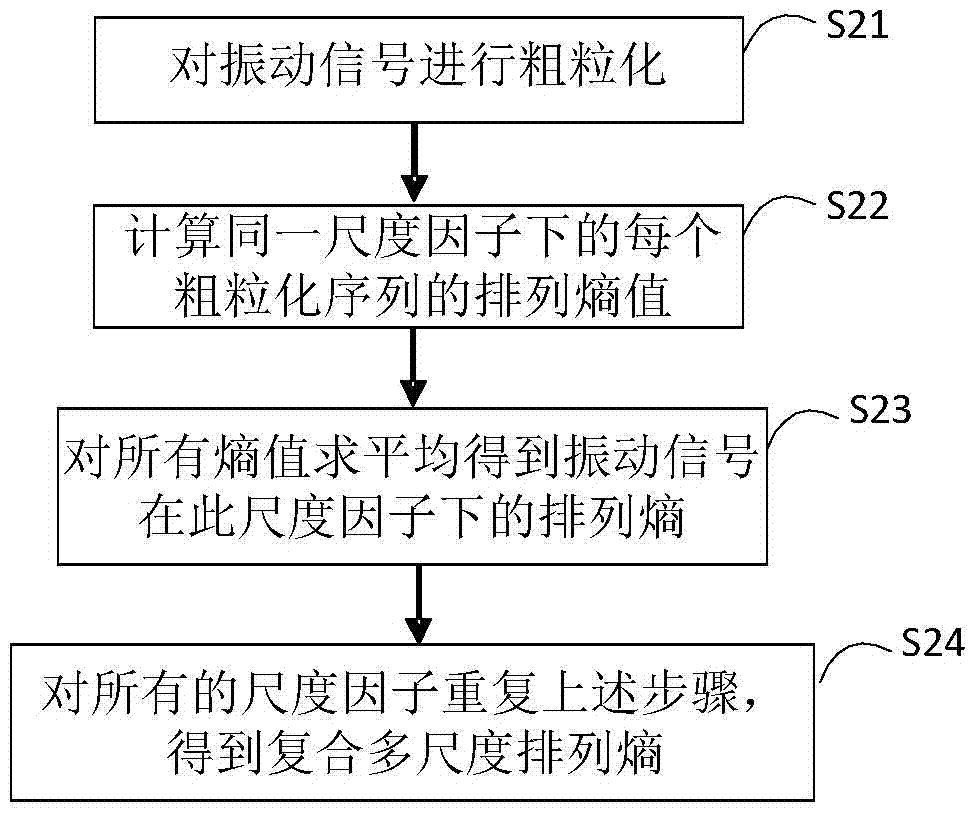

[0065] Step S12, extracting a plurality of composite multi-scale permutation entropy values from the vibration signal (for example, the vibration acceleration signal).

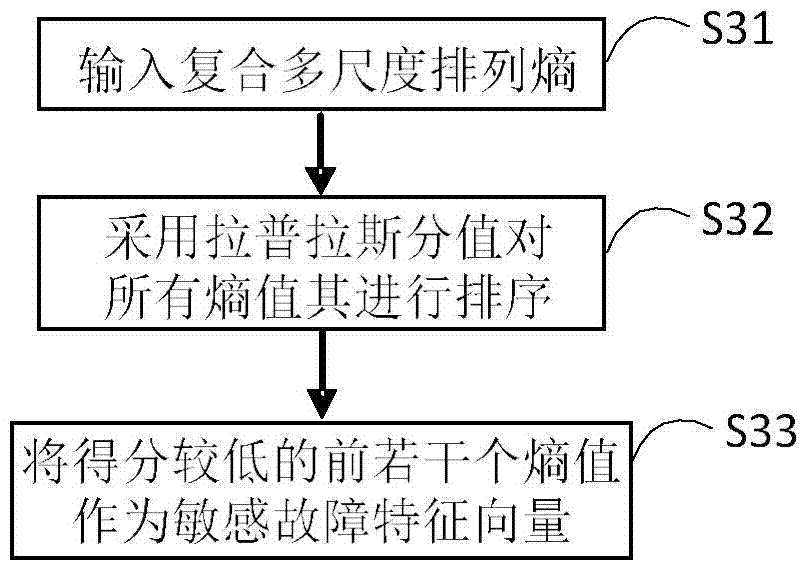

[0066] Step S13 , performing feature dimensionality reduction on the compound permutation entropy value by using the Laplacian score.

[0067] Step S14, taking the first several composite multi-scale permutation entropy values with lower scores after dimensionality reduction as feature vectors, and dividing them into multiple training samples and multiple testing samples.

[006...

Embodiment 2

[0135] In this embodiment, a rolling bearing is used as a fault object to further illustrate the effectiveness of the diagnosis method. see Figure 12 , Figure 12 It is the time-domain waveform diagram of vibration signals in four states of rolling bearing normal (Normal), rolling element fault (BEF), inner ring fault (IRF) and outer ring fault (ORF).

[0136] Test data The test bearing is 6205-2RSJEM SKF deep groove ball bearing. The single point fault is arranged on the bearing by EDM technology. The fault diameter is 0.5334mm, the depth is 0.2794mm, the bearing speed is 1797r / min, and the signal sampling frequency is 12kHz , the vibration signals of four states of normal, inner ring single-point electric erosion, outer ring single-point electric erosion and rolling element single-point electric erosion are collected, and 20 sets of data are intercepted for each state, and the length of each data is 4096.

[0137] Three samples are randomly selected from each of the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com