Magnetic core applied to reactor and reactor

A reactor and magnetic core technology, applied in the direction of transformer/inductor magnetic core, inductance with magnetic core, magnetic core/magnetic yoke, etc. High saturation magnetic flux density and other problems, to achieve the effect of reducing winding eddy current loss, reducing core eddy current loss, and large saturation current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

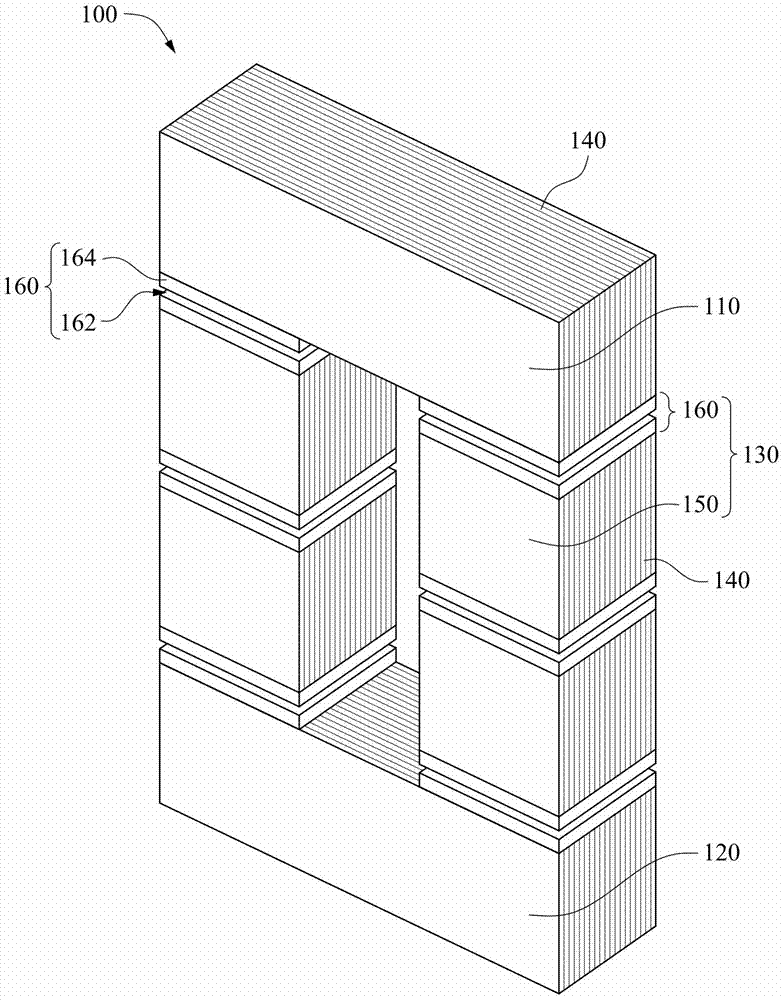

Image

Examples

experiment example 1

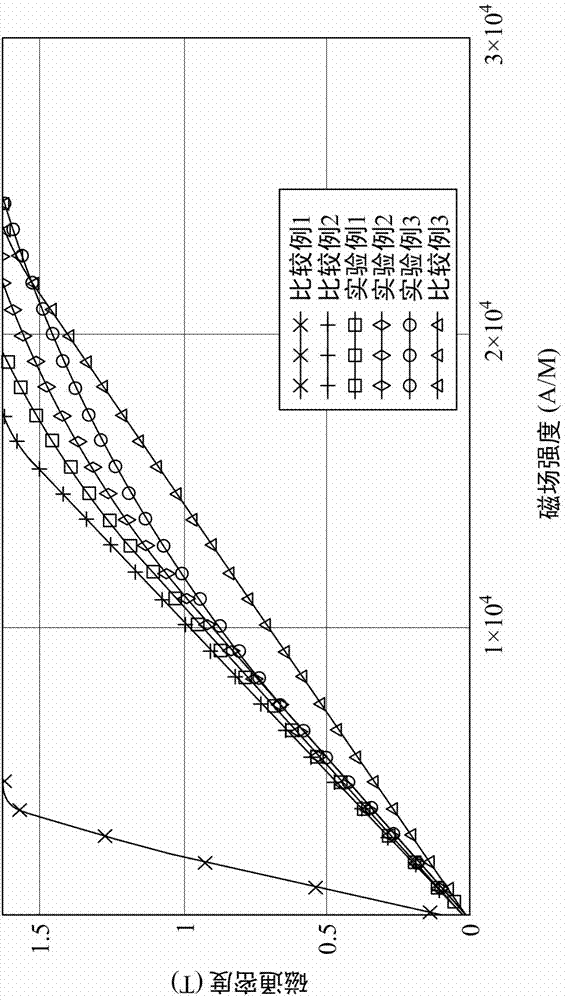

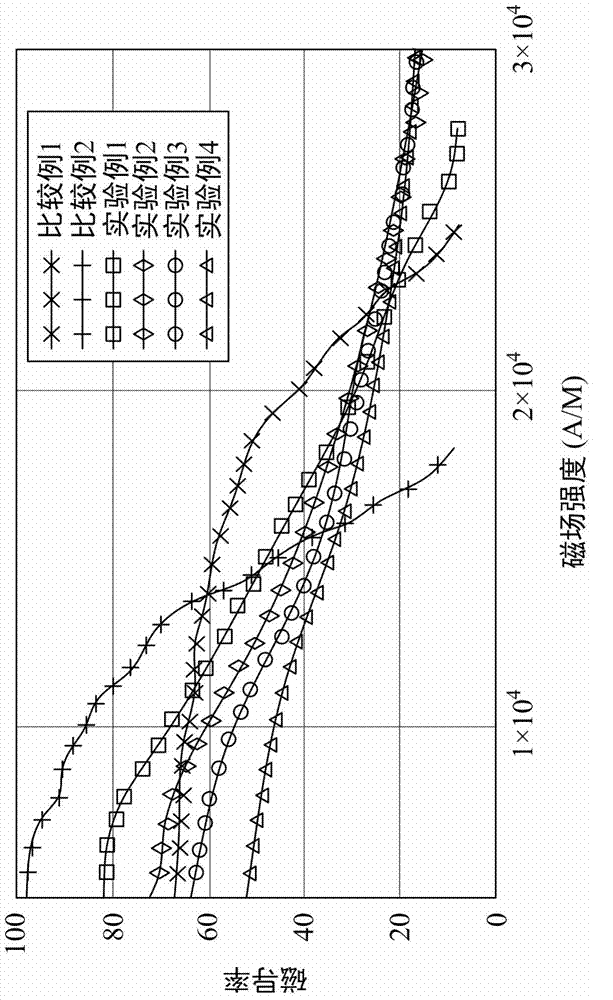

[0058] The saturation characteristics of Experimental Example 1 and Experimental Example 2 are closer to Comparative Example 2 at light load, and closer to Comparative Example 1 at heavy load. Similarly, the saturation characteristics of Experimental Example 5, Experimental Example 6, and Experimental Example 7 are closer to Comparative Example 4 at light loads, and closer to Comparative Example 3 at heavy loads. The experimental results confirm that the magnetic core can indeed obtain a more balanced performance of light and heavy load inductance values.

[0059] However, the volume of the balanced magnetic unit inserted in the magnetic core of the mixed material is not as large as possible. image 3 and Figure 4 It can be seen from the figure that, relative to the air gap, the insertion of too much balanced magnetic unit, such as Experiment 4 and Experiment 8, will make the saturation curve more gentle, but because the initial magnetic permeability of the core is too large...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com