Medium loading resonator

A dielectric loading and resonator technology, applied in the direction of resonators, waveguide devices, electrical components, etc., can solve the problems of reduced production efficiency, increased product scrap rate, unusable, etc., and achieve simplified structure, reduced production costs, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

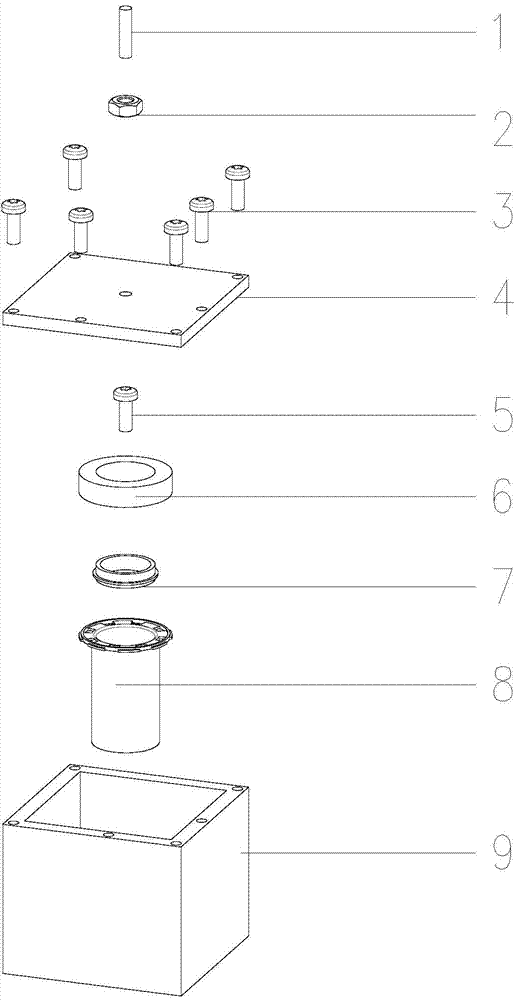

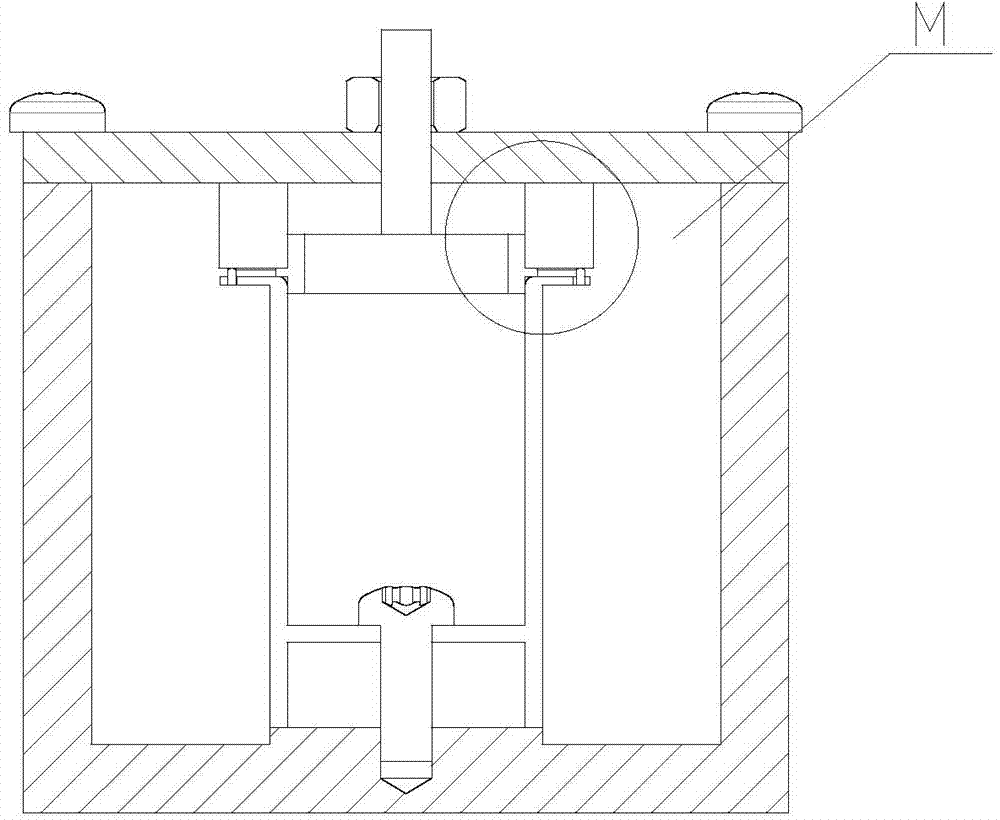

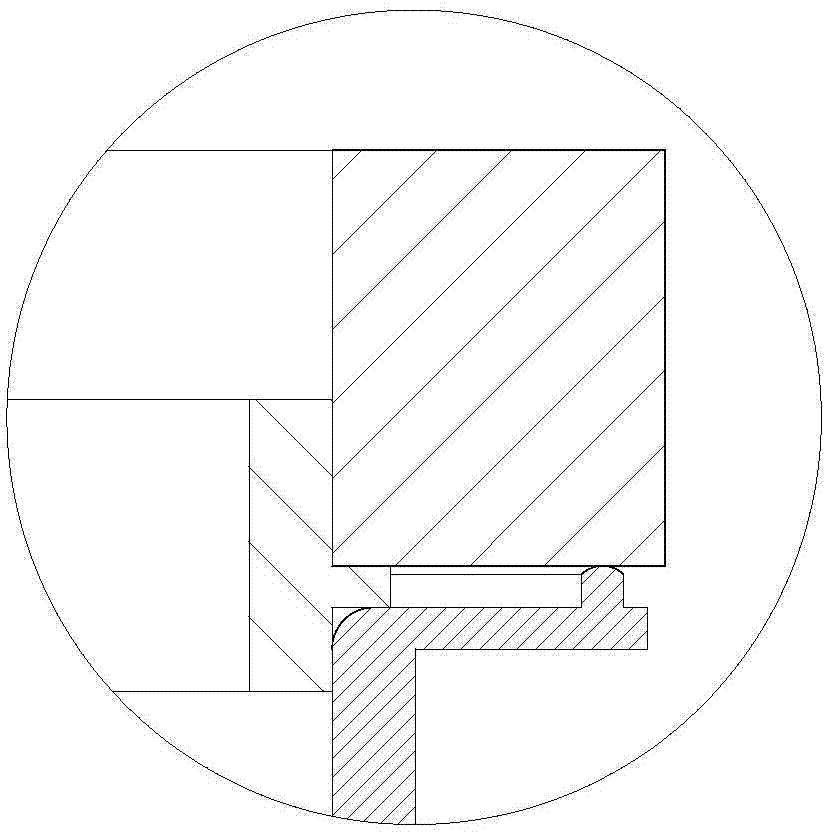

[0029] see figure 1 , figure 2 , This embodiment relates to a dielectric-loaded resonator, including a tuning screw 1 , a nut 2 , an assembly screw 3 , a cover plate 4 , a connecting screw 5 , a loading medium 6 , a positioning seat 7 , a metal resonator rod 8 and a metal cavity 9 . The tuning screw 1 is installed on the cover plate 4 through the nut 2 , the cover plate 4 is located on the metal cavity 9 , and the metal resonant rod 8 is fixed on the bottom of the metal cavity 9 . The positioning seat 7 is arranged between the lower end surface of the loading medium 6 and the top of the metal resonant rod 8 , and the connection between the positioning seat 7 and the top of the metal resonant rod 8 is conducted through an elastic metal piece.

[0030] Wherein, the loading medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com