Multi-dimensional lossless rotation-stopping optical fiber rotary connecting device and use method

A rotary connection, multi-dimensional technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of replacing carbon brushes, easy to generate electric sparks, and troublesome application, so as to achieve no optical loss, avoid frictional contact, and avoid twisting and breaking. The effect of fiber optics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

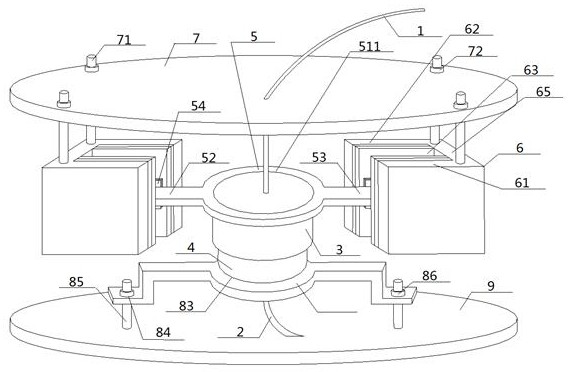

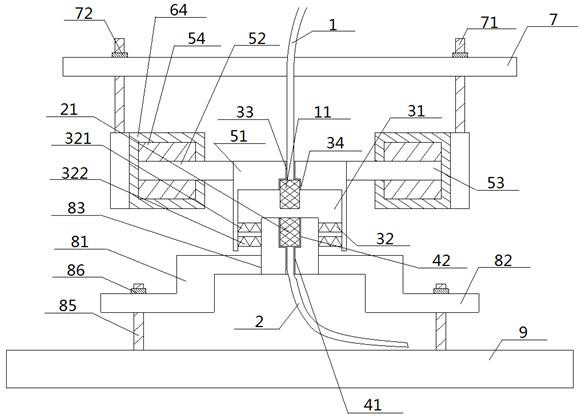

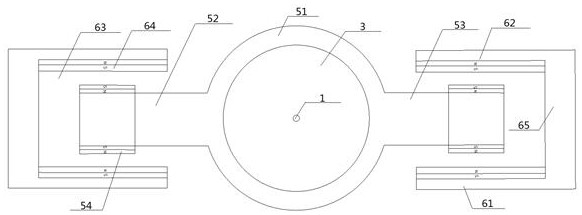

[0049] see figure 1 — image 3 , a multi-dimensional non-destructive stop transformation optical fiber rotary connection device, comprising an upper housing 3, a lower housing 4, a static end optical fiber 1 and a dynamic end optical fiber 2, the outer wall of the upper housing 3 is sleeved with a rotation stop piece 5 , the two ends of the anti-rotation plate 5 are respectively connected with a anti-rotation unit 6, and an inter-shell bearing 32 is arranged in the upper shell cavity 31 in the upper shell 3, and the outer circumference of the inter-shell bearing 32 is connected with the upper shell The inner wall of the chamber 31 is interference-fitted, and the middle part of the inter-shell bearing 32 and the outer wall of the top of the lower housing 4 are interference-fitted; the top end of the optical fiber 1 at the stationary end passes through the metal cover 7 of the unit and extends to the top thereof, static The bottom end of the end optical fiber 1 passes through t...

Embodiment 2

[0052] Basic content is the same as embodiment 1, the difference is:

[0053] The anti-rotation piece 5 includes a middle sleeve 51 and a left anti-rotation arm 52 and a right anti-rotation arm 53 connected to two ends thereof. The middle part of the middle sleeve 51 is provided with an anti-rotation hole 511, and the anti-rotation hole 511 is sleeved On the outer wall of the upper casing 3 , the left anti-rotation arm 52 and the right anti-rotation arm 53 are respectively connected to one anti-rotation unit 6 correspondingly. The anti-rotation unit 6 includes a front anti-rotation wall 61 and a rear anti-rotation wall 62 facing to each other, and an anti-rotation cavity 63 sandwiched between them. The front anti-rotation wall 61 and the rear anti-rotation wall 62 The walls are covered with in-situ magnets 64; the outer ends of the left anti-rotation arm 52 and the right anti-rotation arm 53 extend to the inside of the corresponding anti-rotation chamber 63, and the left anti-...

Embodiment 3

[0055] Basic content is the same as embodiment 1, the difference is:

[0056] The multi-dimensional non-destructive transformation optical fiber rotary connection device also includes a rotary bracket 8, the rotary bracket 8 includes a bracket top base 81 and a bracket chassis 82, and the top of the bracket top base 81 is provided with a bracket through hole 83 to connect with the lower casing. The outer wall of the bottom of 4 carries out interference assembly, and the bottom of bracket top seat 81 is vertically connected with the middle part of bracket chassis 82, and the positions on both sides of bracket chassis 82 on bracket chassis 82 are provided with screw holes 84 respectively, and this screw hole 84 passes through And there is an adjustable screw rod 85, the bottom of this adjustable screw rod 85 is connected with the top of the unit rotor 9, and the top of the adjustable screw rod 85 is threaded with the adjustable nut 86 after passing through the screw hole 84.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com