A kind of steel bar with heating function and its production and use method

A technology of reinforcement and function, applied in the field of civil engineering scientific research, can solve problems such as uneven temperature distribution and uneven magnetic field space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

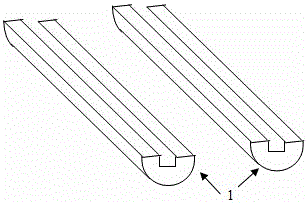

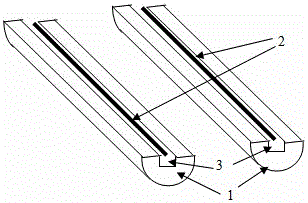

[0028] Embodiment 1: as Figure 1-5 As shown, a steel bar with heating function, including slotted semi-steel bar 1, heating wire 2, and heat-resistant resin binder 3; cut the original steel bar longitudinally and cut out a rectangular shape on the two cut steel bars Groove to form a slotted half steel bar 1; the full length of the heating wire 2 coated with the heat-resistant resin binder 3 is arranged in the rectangular groove of the slotted half steel bar 1; the heat-resistant resin binder 3 is filled Fill the gap of the groove of the slotted half steel bar 1; coat the heat-resistant resin adhesive 3 on the longitudinal cut surface of the slotted half steel bar 1 and bond the two slotted half steel bars 1 together.

[0029] The heating wire 2 is a tungsten wire.

Embodiment 2

[0030] Embodiment 2: as Figure 1-5 As shown, a steel bar with heating function, including slotted semi-steel bar 1, heating wire 2, and heat-resistant resin binder 3; cut the original steel bar longitudinally and cut out a rectangular shape on the two cut steel bars Groove to form a slotted half steel bar 1; the full length of the heating wire 2 coated with the heat-resistant resin binder 3 is arranged in the rectangular groove of the slotted half steel bar 1; the heat-resistant resin binder 3 is filled Fill the gap of the groove of the slotted half steel bar 1; coat the heat-resistant resin adhesive 3 on the longitudinal cut surface of the slotted half steel bar 1 and bond the two slotted half steel bars 1 together.

Embodiment 3

[0031] Embodiment 3: as Figure 1-5 Shown, a kind of manufacture method of the steel bar with heating function, the concrete steps of described method are as follows:

[0032] Step1, cut the original steel bar longitudinally and open a rectangular groove on the two cut steel bars to form a slotted half steel bar 1;

[0033] Step2. Arrange the full length of the heating wire 2 coated with the heat-resistant resin binder 3 in the rectangular groove of the slotted semi-rebar 1;

[0034] Step3, fill the gap of the groove of the grooved semi-rebar 1 with the heat-resistant resin binder 3;

[0035] Step 4. Coat the heat-resistant resin adhesive 3 on the longitudinal cutting surface of the slotted semi-reinforcement bar 1 and bond the two slotted semi-reinforced bars 1 together to form a reinforcing bar with heating function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com