Tray washing machine and method

A technology for cleaning machines and trays, applied in cleaning methods and utensils, cleaning methods using liquid, chemical instruments and methods, etc. It does not meet the requirements of energy saving and environmental protection, etc., to achieve better cleaning effect, improve cleaning effect, and facilitate drainage and air drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

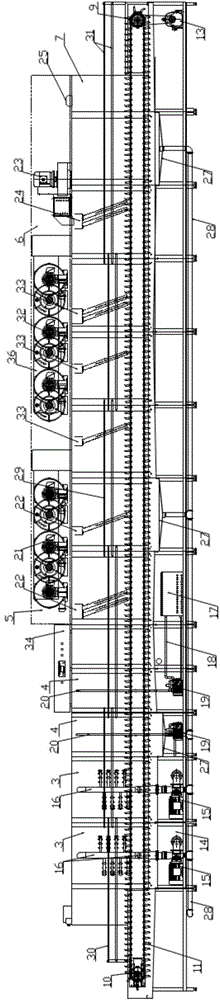

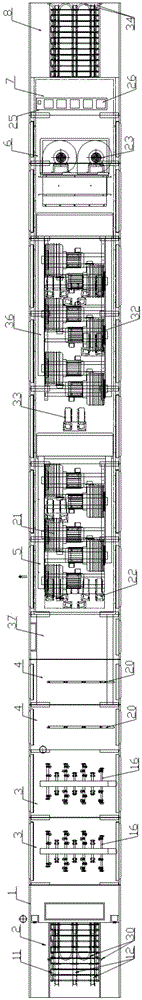

[0049] Such as Figure 1 to Figure 7 As shown, a pallet cleaning machine includes a body 1, the body 1 is a box structure, including a material conveying mechanism that runs through the inside of the body, a feeding section 2, and a water initial washing section 3 arranged in sequence from front to back , cleaning section 4, hot air shower section 5, hot air heating section 6, ion air shower section 7 and discharge section 8;

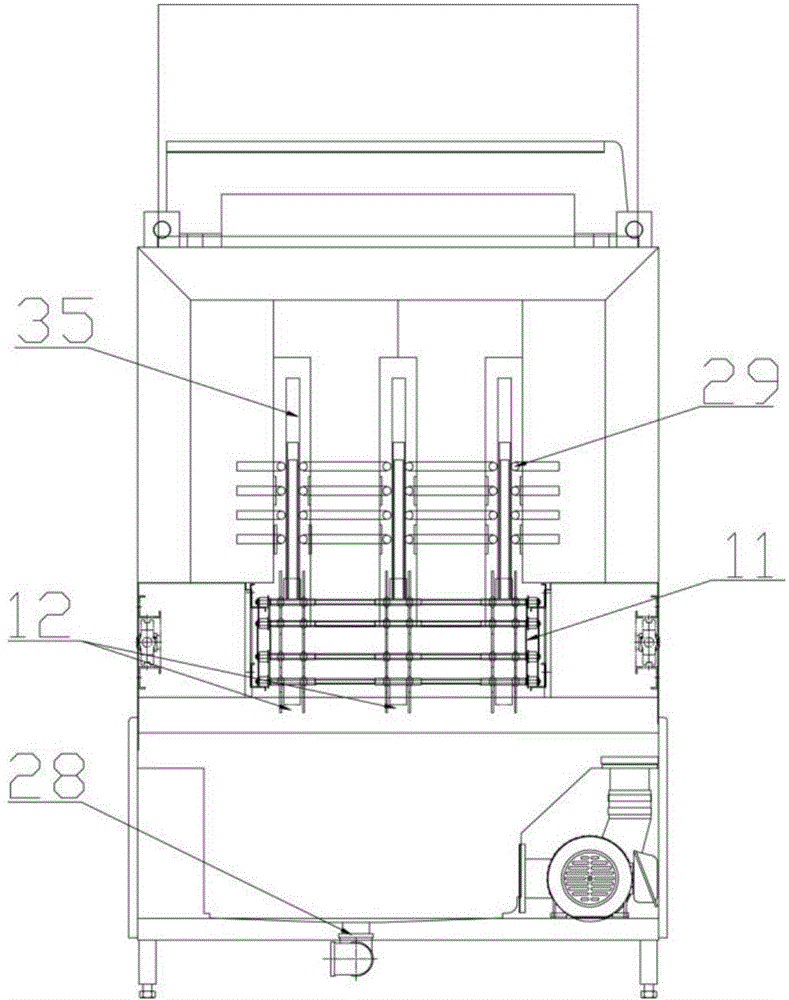

[0050] The material conveying mechanism includes a driving roller 9, a driven roller 10 and a conveying chain 11 surrounding the driving roller 9 and the driven roller 10, and the conveying chain 11 is provided with a plurality of vertically placed waiting The conveying card position 12 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com