Flexible ship body connecting mechanism of combined type semi-submerged ship

A connecting mechanism and semi-submersible ship technology, applied in the field of hull connection structure and flexible hull connection mechanism of combined semi-submersible ships, can solve the problems that cannot meet the maneuverability, safety and seakeeping of combined semi-submersible transport ships, and achieve Overcome reliability and maneuverability, high reliability, effect of solving connection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

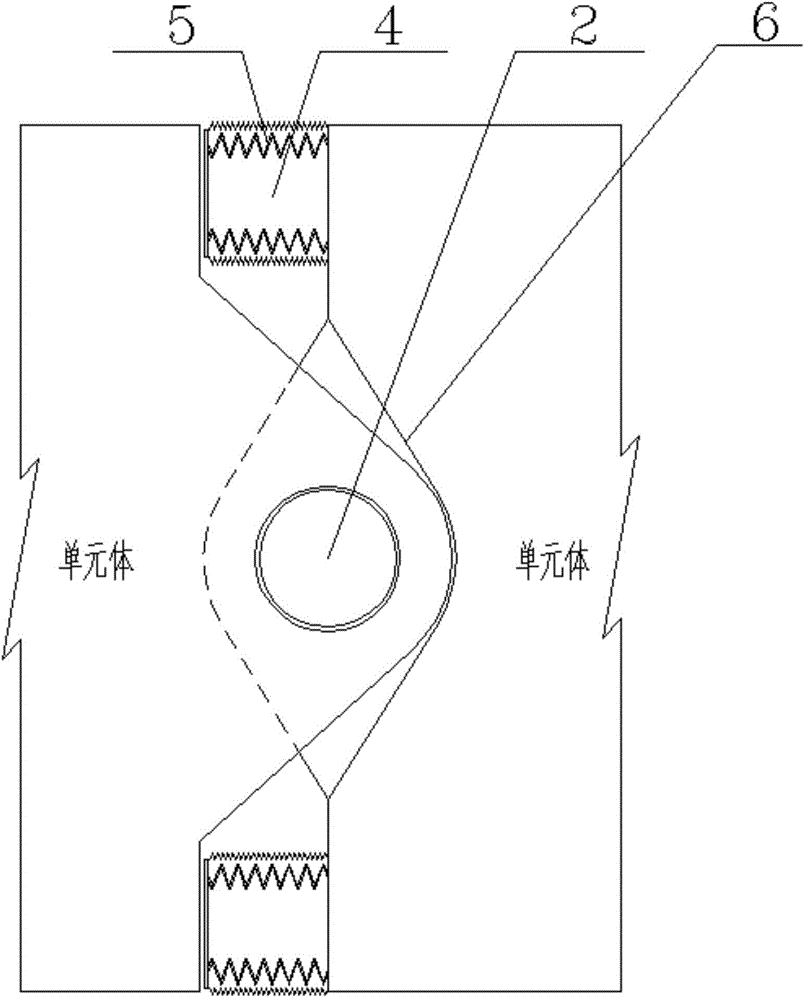

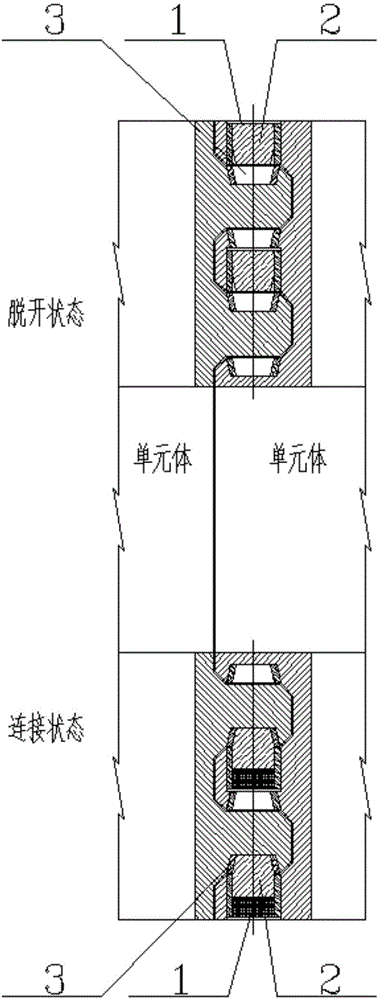

[0022] see Figure 1-Figure 2 , a combined semi-submersible flexible hull connection mechanism, the connection direction of the hull is set as the X-axis, and the horizontal and vertical direction is the Y-axis; the connection between two adjacent hulls is divided into a first unit body and a second unit body, the first unit body is provided with a plurality of bearings 3 along the Y direction, and the second unit body is provided with conical pins 2 corresponding to the bearings 3, and each conical pin 2 is controlled by its own hydraulic cylinder 1 drive, insert or extract the bearing 3 along the Y direction, realize the connection and separation of the hull, and the first unit body and the second unit body can rotate relatively around the tapered pin 2; the first unit body or The upper and lower parts of the second unit body are provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com