Antistatic ABS (acrylonitrile butadiene styrene) plastic

An ABS plastic, anti-static technology, applied in the field of ABS plastics, can solve the problems such as the unsatisfactory anti-static effect of ABS plastics, and achieve the effects of not easy to absorb dust, excellent anti-static properties, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0024] Each raw material was weighed according to the data corresponding to Examples 1-4 in Table 1.

[0025] In the high-speed mixer, control the speed of the high-speed mixer at 350 rpm at room temperature, mix for 5 minutes, take it out and transfer it to a twin-screw extruder, extrude and granulate at a temperature of 180°C, and control the speed of the screw machine at 400 rev / min, the antistatic ABS plastic is obtained.

[0026] Table 1: Antistatic ABS plastic formula table (unit: kg)

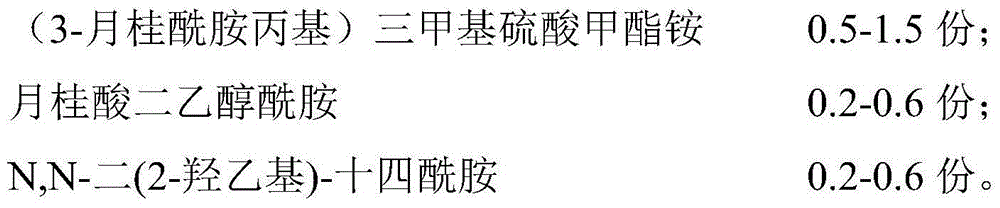

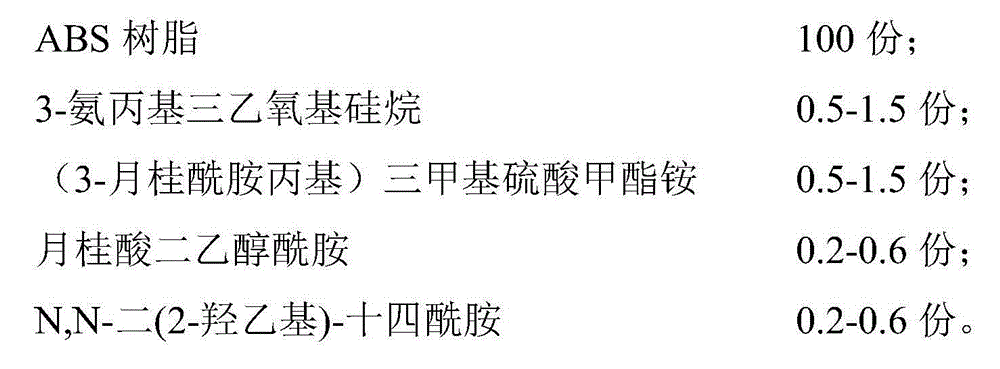

[0027] raw material Example 1 Example 2 Example 3 Example 4 ABS resin 100 100 100 100 3-Aminopropyltriethoxysilane 1 1 1 1 (3-Lauryl amidopropyl) trimethyl ammonium methyl sulfate 1 1 1 1 Lauric acid diethanolamide - 0.6 - 0.3 N,N-bis(2-hydroxyethyl)-tetradecamide - - 0.6 0.3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com