Air foot adopting direct air supply and provided with throttling nozzles and single floating plate

A throttle and gas foot technology, applied in the field of gas foot, can solve the problems of inconvenient replacement of the throttle nozzle and complicated structure of the gas foot, and achieve the effects of improving maintenance efficiency and adaptability, reducing the difficulty of processing and assembly, and shortening the development cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

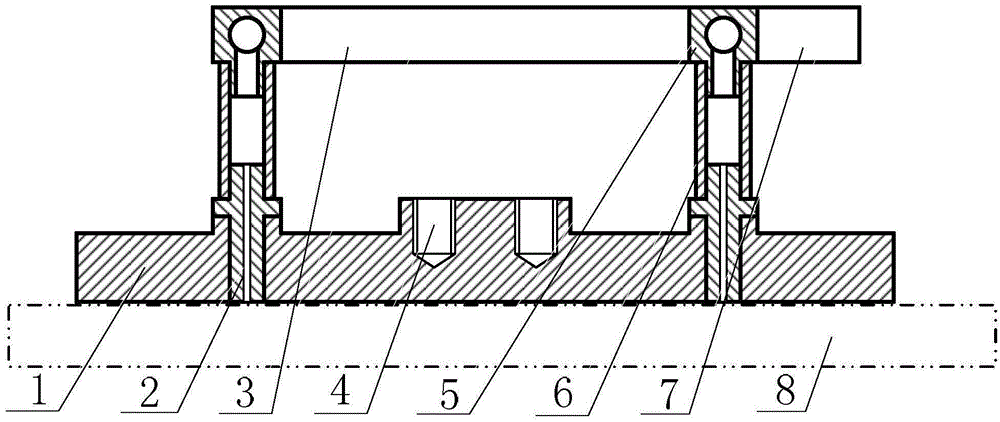

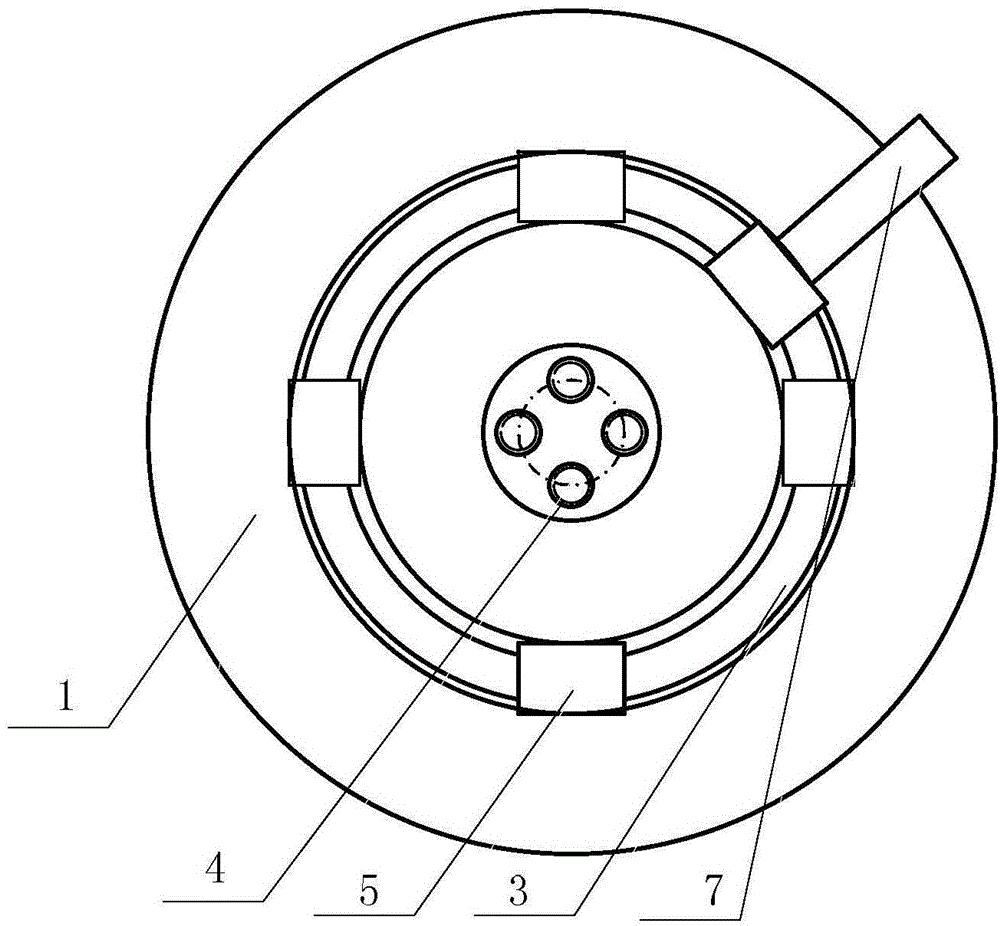

[0016] Specific implementation mode one: the following combination figure 1 and figure 2 Describe this embodiment, the throttle nozzle directly supplies air to the single floating plate air foot in this embodiment, which includes the air foot base plate 1, the throttle nozzle 2, the annular air supply pipe 3, the fastening connection hole 4, the quick connection tee 5, Throttle nozzle air supply pipe 6 and intake pipe 7,

[0017] The air foot base plate 1 is arranged in cooperation with the air flotation platform 8. On the air foot base plate 1, N threaded holes are evenly arranged along the circumferential direction in the middle of the radial direction, and N is an integer greater than or equal to 3. Each threaded hole corresponds to Install a throttle nozzle 2, each throttle nozzle 2 is correspondingly inserted into the head end of a throttle nozzle air supply pipe 6, and the end of each throttle nozzle air supply pipe 6 communicates with the annular air supply pipe 3 th...

specific Embodiment approach 2

[0022] Specific implementation mode two: the following combination figure 1 Describe this embodiment, this embodiment will further explain Embodiment 1, the middle section of the outer circular surface of the throttle nozzle 2 has a ring-shaped protrusion, and the ring-shaped protrusion makes the outer ring surface of the throttle nozzle 2 form a stepped surface, and the throttle nozzle 2 The stepped surface is positioned and fixed with the threaded hole and the throttle nozzle air supply pipe 6 .

[0023] The outer surface of the throttle nozzle 2 forms a stepped cylindrical structure, and its center is processed with a Φ0.1mm-0.5mm hole by precision drilling or laser drilling. The diameter of the foot and the number of orifices are designed. The throttle nozzle 2 is mounted on the air foot base plate 1 through thread fit, and the positioning is realized through the stepped surface, so as to ensure the relative position accuracy between the lower surface of the throttle noz...

specific Embodiment approach 3

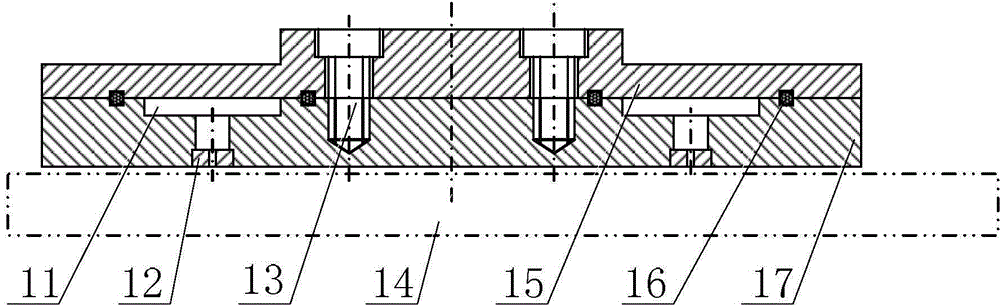

[0024] Embodiment 3: This embodiment further describes Embodiment 1 or 2. A pressure regulating valve and an on-off valve are installed on the throttle nozzle air supply pipe 6 .

[0025] Installing a pressure regulating valve and an on-off valve on the throttle nozzle air supply pipe 6 can realize independent control of the throttle nozzle 2 gas supply pressure and on-off. Close the on-off valve of the blocked throttle nozzle, and the replacement of the blocked throttle nozzle can be realized without cutting off the gas.

[0026] The throttle nozzle of the air foot in the present invention directly supplies air from the annular air supply pipe through the air supply pipe of the throttle nozzle, cancels the air sealing plate in the traditional air foot, reduces the sealing requirements of the air foot substrate, and thus reduces the processing and assembly At the same time, the threaded fit between the throttle nozzle and the air foot base plate is adopted, and the stepped sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com