a sealing plug

A technology of sealing and blocking parts, which is applied in the direction of engine sealing, engine components, control valves, etc., can solve the problems that foreign matter cannot be discharged at the threshold, and the structure of sealing and blocking parts is unreasonable, so as to achieve the effect of preventing corrosion and being easy to assemble

Active Publication Date: 2017-06-06

BEIQI FOTON MOTOR CO LTD

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] For this reason, the technical problem to be solved by the present invention lies in the problem that the unreasonable structure of the existing sealing block used for the sill beam process hole of the body-in-white leads to the problem that the foreign matter inside the sill cannot be discharged, and then a new block structure is provided to prevent dust, Water, oil and other foreign matter enter the sill beam through the process hole, and at the same time, the dust, water, oil and other foreign matter entering the sill beam from the gap of the sheet metal lap can be discharged to prevent corrosion of the sheet metal

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

other Embodiment approach

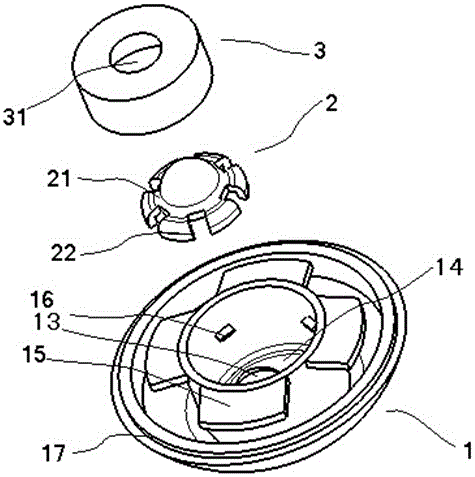

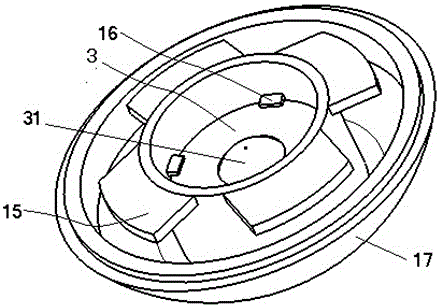

[0046] In other embodiments, the cavity 12 can also be integrally formed by the blocking body 1, and the inner wall of the blocking body 1 is formed with a partition with the through hole 31, which is connected with the blocking body 1. The part between the closed ends 14 of the body 1 is the cavity 12 . During installation, the one-way through-stop member 2 can directly extend into the through-stop hole 31 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

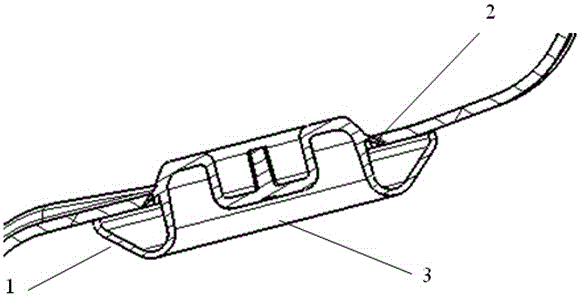

The invention discloses a seal plug, and belongs to the field of design and manufacturing of plugs for technological holes in car bodies. The seal plug comprises a plug body (1), wherein a clamping part is arranged on the plug body (1); the plug body (1) penetrates through a technological hole, and is clamped in the technological hole through the clamping part; a cavity (12) is formed in the interior of the plug body (1); a one-way go-no go piece (2) is arranged in the cavity (12); a go-no go hole (31) used for being matched with the one-way go-no go piece (2) to ensure one-way penetration of a foreign matter is formed in one end of the cavity (12); a communication hole (13) is formed in the other end of the cavity (12). The seal plug is used for preventing such foreign matters as dust, water and an oil liquid from entering a doorsill beam through the technological hole; meanwhile, dust, water, the oil liquid and other foreign matters which enter the doorsill beam through a sheet metal overlap gap can be removed, so as to protect sheet metal from corrosion; the seal plug is particularly suitable for sealing of a technological hole in a body-in-white doorsill beam.

Description

technical field [0001] The invention belongs to the field of sealing plugs, in particular to a sealing plug used for the lower process hole of the door sill beam of an automobile body in white. Background technique [0002] In order to ensure the welding performance of the car body in white, the fluidity of the electrophoretic fluid and the passability of the electric field during the electrophoresis process, it is necessary to open welding holes, electrophoresis drain holes and anti-electromagnetic shielding holes on the body. After the body-in-white is manufactured, in order to prevent foreign matter such as water and oil from intruding into the passenger compartment through the process hole, it is necessary to install a process hole sealing plug to seal the process hole. [0003] At present, in order to prevent foreign matter such as water and oil from intruding into the passenger compartment through the process hole, the process hole of the sill beam of the body-in-white...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16J15/06

CPCF16J15/022F16J15/061F16J15/064F16J15/104F16K15/021

Inventor 朱成科刘珊珊未岩罗来龙

Owner BEIQI FOTON MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com