LED down lamp

A technology of LED downlights and LED lamps, which is applied in lighting and heating equipment, point light sources, lighting devices, etc., can solve the problems of increasing the weight of downlights, unsightly appearance, and inability to heat curved gardens, etc., and achieves convenient use and transparency Good light effect, easy to make effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

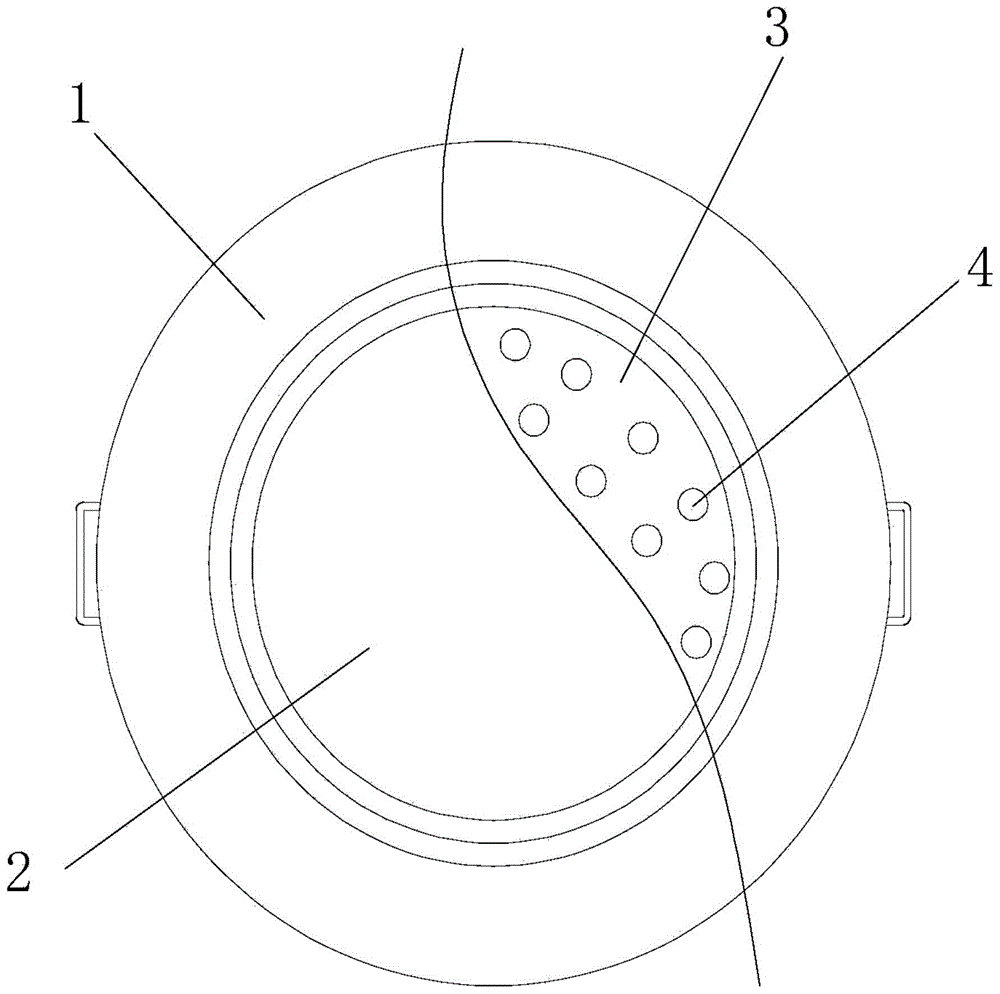

[0021] see figure 1 , in an embodiment of the present invention, an LED downlight includes an LED downlight body 1, a light-transmitting plate 2, a driving circuit board 3, an LED lamp 4 and a built-in driving power supply circuit, and the light-transmitting plate 2 is installed on the LED downlight On the light outlet of the main body 1, the LED driving circuit board 3 is installed in the accommodation space between the LED downlight main body 1 and the light-transmitting plate 2, and the LED lamp 4 is packaged on the LED driving circuit board 3 and connected with the LED driving circuit board 3. The circuit board 3 is electrically connected, and the LED driving circuit board 3 is provided with a built-in driving power circuit, and the built-in driving power circuit is electrically connected with the LED lamp 4, so that the LED light source part and the power driving part are designed in one, and the light-transmitting The raw materials of board 2 according to parts by weight...

Embodiment 2

[0031] see figure 1 , in an embodiment of the present invention, an LED downlight includes an LED downlight body 1, a light-transmitting plate 2, a driving circuit board 3, an LED lamp 4 and a built-in driving power supply circuit, and the light-transmitting plate 2 is installed on the LED downlight On the light outlet of the main body 1, the LED driving circuit board 3 is installed in the accommodation space between the LED downlight main body 1 and the light-transmitting plate 2, and the LED lamp 4 is packaged on the LED driving circuit board 3 and connected with the LED driving circuit board 3. The circuit board 3 is electrically connected, and the LED driving circuit board 3 is provided with a built-in driving power circuit, and the built-in driving power circuit is electrically connected with the LED lamp 4, so that the LED light source part and the power driving part are designed in one, and the light-transmitting The raw materials of board 2 include: 90 parts of polymer...

Embodiment 3

[0041] see figure 1 , in an embodiment of the present invention, an LED downlight includes an LED downlight body 1, a light-transmitting plate 2, a driving circuit board 3, an LED lamp 4 and a built-in driving power supply circuit, and the light-transmitting plate 2 is installed on the LED downlight On the light outlet of the main body 1, the LED driving circuit board 3 is installed in the accommodation space between the LED downlight main body 1 and the light-transmitting plate 2, and the LED lamp 4 is packaged on the LED driving circuit board 3 and connected with the LED driving circuit board 3. The circuit board 3 is electrically connected, and the LED driving circuit board 3 is provided with a built-in driving power circuit, and the built-in driving power circuit is electrically connected with the LED lamp 4, so that the LED light source part and the power driving part are designed in one, and the light-transmitting The raw materials of board 2 according to parts by weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com