Sintering machine water seal mobile hot air sintering sealing device

A sintered sealing and mobile technology, which is applied to the sealing of the engine, mechanical equipment, engine components, etc., to achieve the effect of ensuring the penetration rate and accelerating the combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

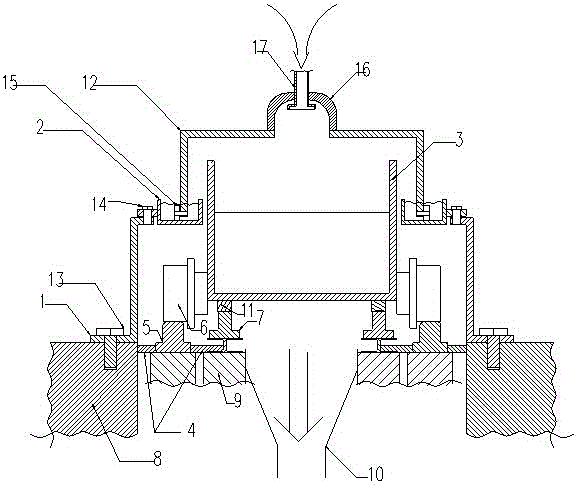

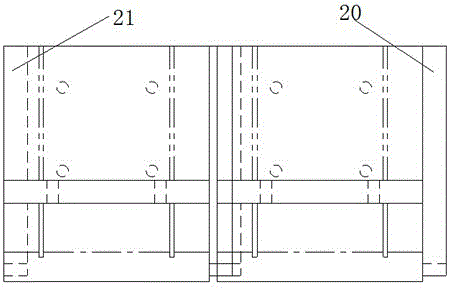

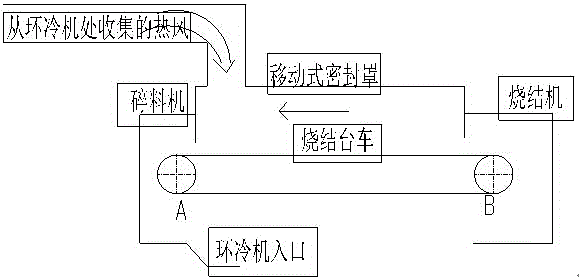

[0018] according to Figure 1-3 , the sintering machine water seal mobile hot air sintering sealing device, including a bracket 1, a U-shaped water seal groove 2, and a shield 12, the bracket is installed on the trolley foundation 8 on both sides of the trolley through bolts, and the U-shaped water The sealing groove is connected to the upper end of the support by bolts, and the lower end of the shield walks in the U-shaped water sealing groove through the traveling wheels 15. At this time, the shield completely covers the space at the upper end of the sintering trolley and the top of the shield is higher than the side block of the trolley. Plate 3, a connection cover 16 is arranged on the top of the cover, and a hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com