Verifying device for gear of textile machine

A technology for textile equipment and inspection devices, which is applied in the field of inspection devices for textile equipment gears, and can solve the problems that the accuracy of textile equipment gears cannot be guaranteed, cannot meet the requirements of enterprise production, and cannot be inspected for precision indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

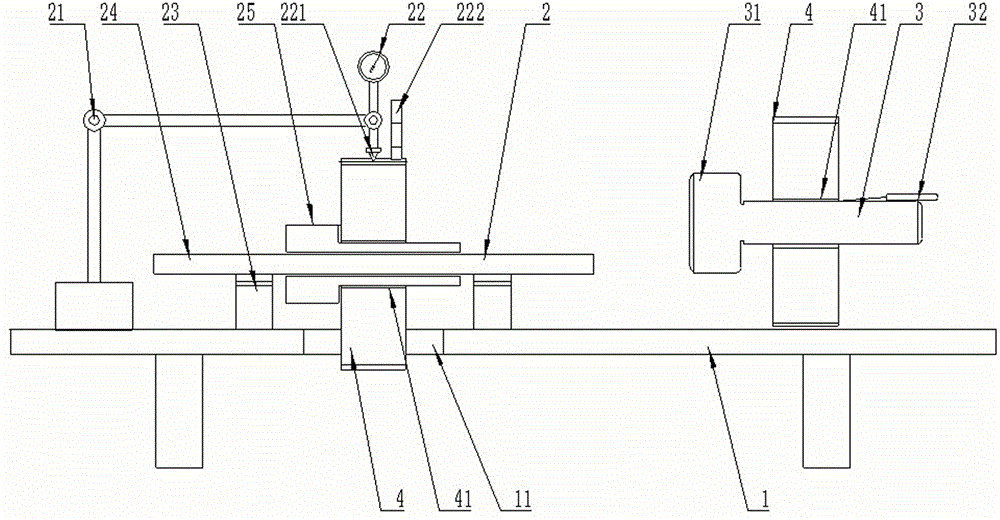

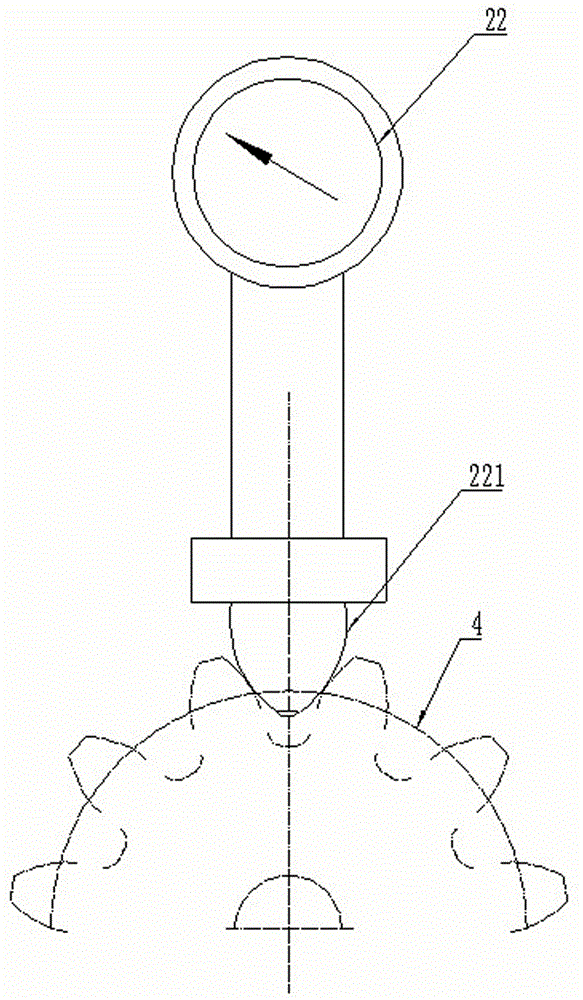

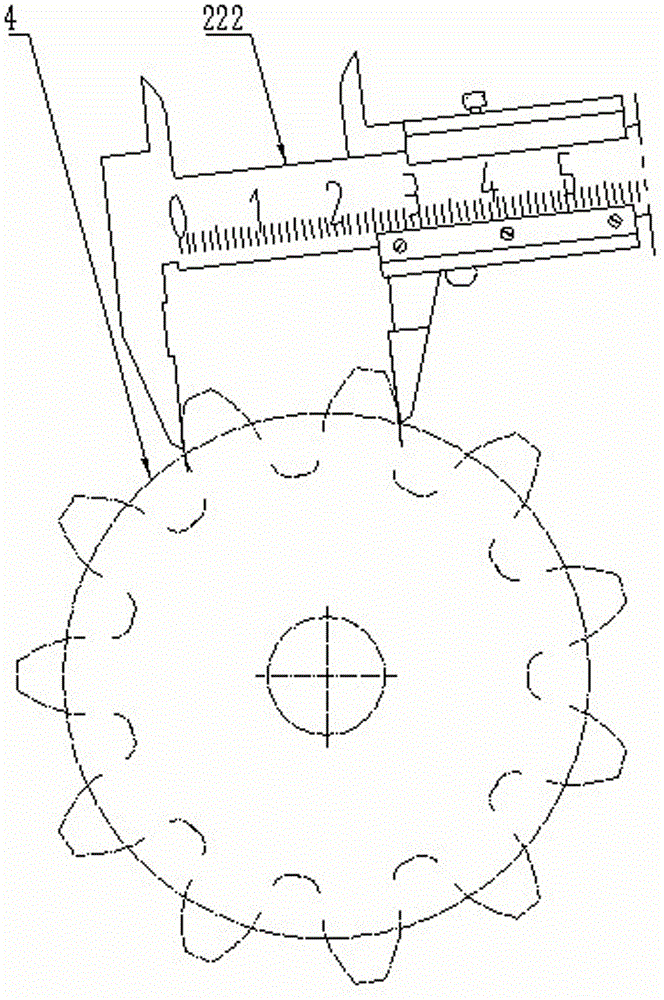

[0018] The inspection device for textile equipment gears of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0019] Depend on figure 1 , figure 2 , image 3 , Figure 4 It can be seen that the inspection device for gears of textile equipment of the present invention includes an inspection platform 1, and the inspection platform 1 is provided with a calibration assembly 2 and a calibration assembly 3, and the inspection platform 1 is also provided with a bar-shaped hole 11; The calibration gear assembly 2 includes a bracket 21 and a "V"-shaped table 23, a dial indicator 22 is connected to one end of the bracket 21, a mandrel 24 is provided on the "V"-shaped table 23, and a positioning sleeve 25 is provided outside the mandrel 24; The hole alignment assembly 3 includes a hole alignment shaft 31 and a plug gauge 32 .

[0020] see figure 1 , figure 2 , image 3 , Figure 4 , when the present invention wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com