Liquid chromatograph and column oven for use therein

A technology of liquid chromatograph and column temperature box, applied in the field of liquid chromatograph, can solve problems such as liquid leakage and leakage sensor, and achieve the effect of eliminating false detection of liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

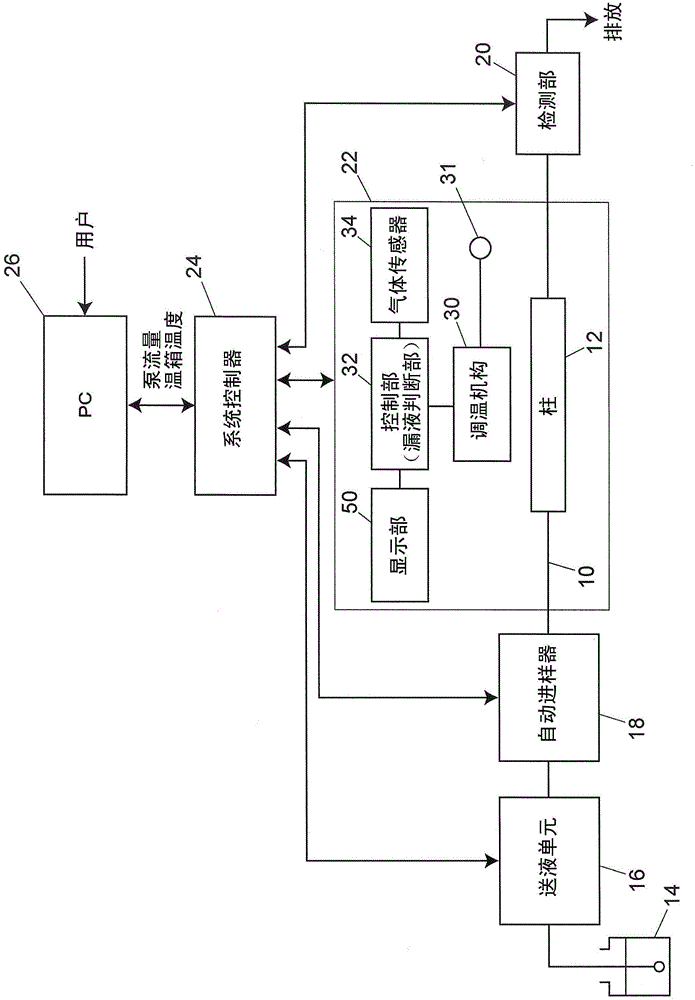

[0030] figure 1 is a diagram showing a liquid chromatograph of an example. In order to supply a mobile phase 14 to an analysis channel 10 including a separation column 12 , a liquid delivery unit 16 is provided on the most upstream side. As an example of the liquid-feeding unit 16, a liquid-feeding unit having a liquid-feeding pump and having an independent function is used. The liquid delivery unit 16 is connected with the system controller 24 , and controls the liquid delivery action of the mobile phase according to the conditions set in the system controller 24 .

[0031] In order to inject a sample into the analysis channel 10 supplied with the mobile phase 14 , a sample injector 18 is provided in the analysis channel 10 between the liquid-feeding unit 16 and the separation column 12 . An autosampler 18 is used as an example of the sample injection unit 18 . The autosampler 18 is also connected to the system controller 24 , and injects a set amount of the sample set in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com