Manufacturing method of vertical double-diffusion metal oxide semiconductor field effect transistor

An oxide semiconductor and vertical double-diffusion technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as waste of manpower and material resources, changes in electrical parameters of VDMOS devices, and soft breakdown of VDMOS devices. To avoid waste and solve the effect of drain-source soft breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

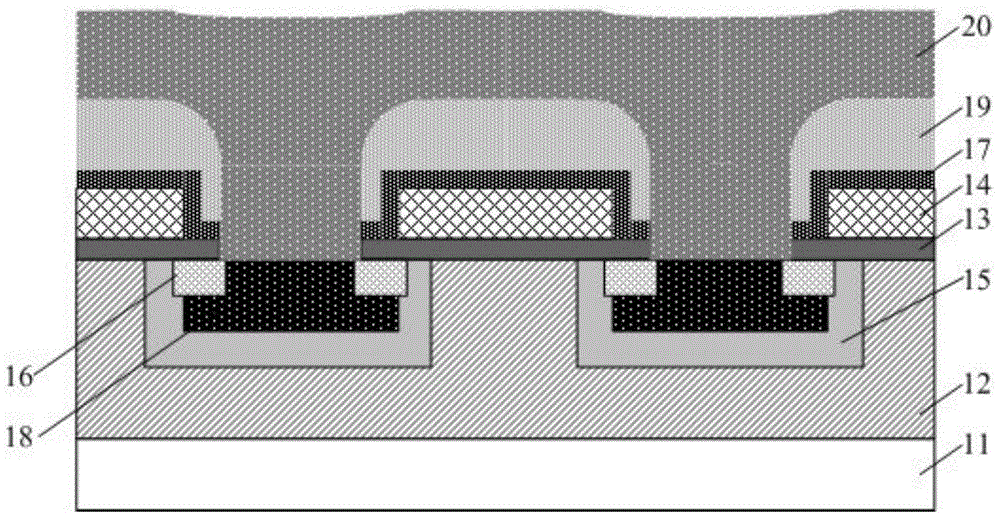

[0025] The technical solution of the present invention will be described in further detail below through specific embodiments and accompanying drawings.

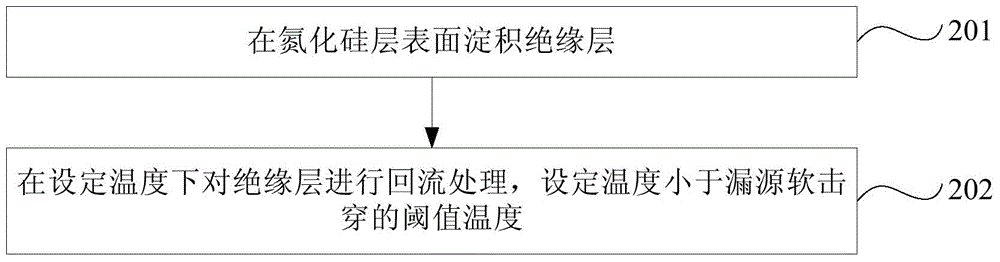

[0026] figure 2 A schematic flowchart of an embodiment of a method for manufacturing a vertical double-diffused metal-oxide-semiconductor field effect transistor provided by the present invention. like figure 2 As shown, the method may specifically include:

[0027] S201, depositing an insulating layer on the surface of the silicon nitride layer.

[0028] S202, performing reflow treatment on the insulating layer at a set temperature, where the set temperature is lower than a threshold temperature of drain-source soft breakdown.

[0029] refer to figure 1 Those skilled in the art can understand that before step S201, the following steps are also included: sequentially forming an epitaxial layer 12, a gate oxide layer 13, a polysilicon layer 14, a body region 15, a source region 16, and a silicon nitride layer on the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com