Pressurizing system for lithium ion battery pole group

A technology of lithium ion battery and pressurization system, applied in the field of pressurization system, can solve the problems of affecting the safety performance of the battery, precipitation of lithium, and easily crushing the pole group, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

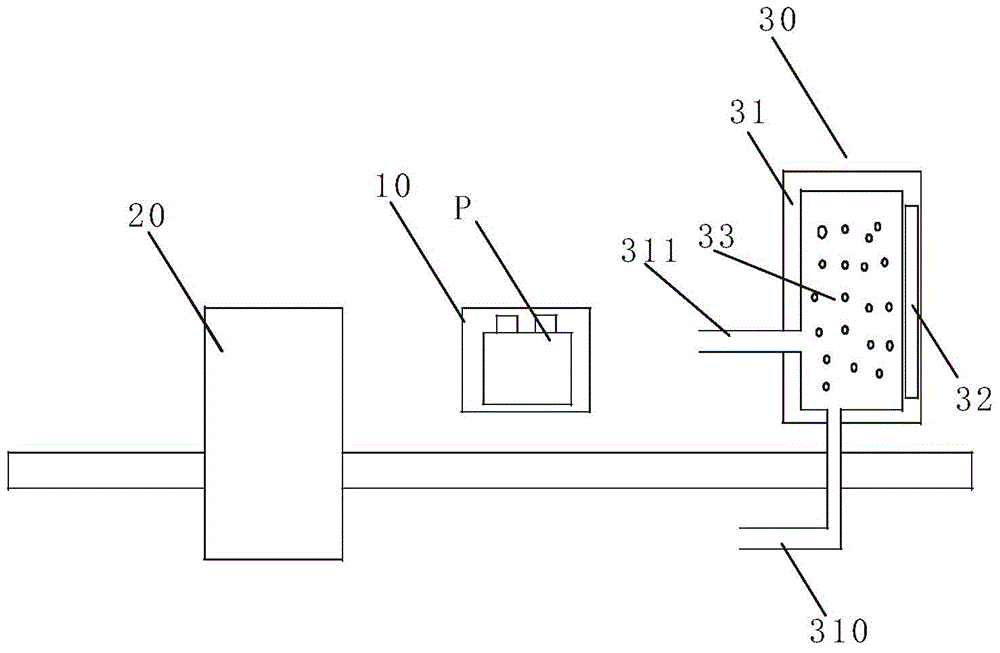

[0013] Next, a pressurization system for a lithium-ion battery electrode assembly as an example of the present invention will be described based on the drawings.

[0014] figure 1 is a schematic diagram showing the pressurization system of the lithium ion battery electrode assembly of the present invention.

[0015] Such as figure 1 As shown, the pressurization system of the lithium ion battery pole group of the present invention has: a flexible packaging bag 10, which encapsulates the lithium ion battery pole group P; The bag 10 is vacuumized, and then the flexible packaging bag 10 is sealed; the isostatic pressing equipment 30 includes a pressure vessel 31, a heater 32 arranged on the pressure vessel 31, and a pressure medium 33 contained in the pressure vessel 31, through The pressure medium 33 pressurizes the lithium-ion battery electrode group P packaged in the flexible packaging bag 10 . In addition, the pressure vessel 31 has a high-pressure medium inlet 310, a high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com