Heat-resistant foam double-side adhesive tape and preparation method thereof

A double-sided adhesive tape and foam technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of poor mechanical properties and thermal stability of foam tapes, affecting structural stability, and prone to deformation, etc., to achieve Uniform and fine cell structure, good dispersion and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

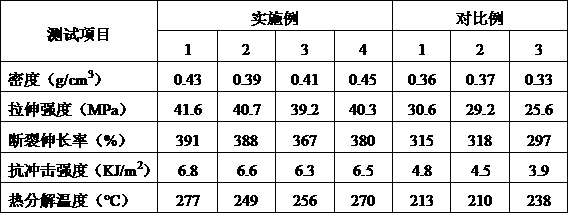

Examples

Embodiment 1~4

[0032] Embodiments 1 to 4: A heat-resistant foam double-sided adhesive tape, comprising a foam layer and an adhesive layer arranged on the upper and lower surfaces of the foam layer,

[0033] The thickness of the foam layer is 100-1000 μm, and the adhesive layer is an acrylic adhesive layer.

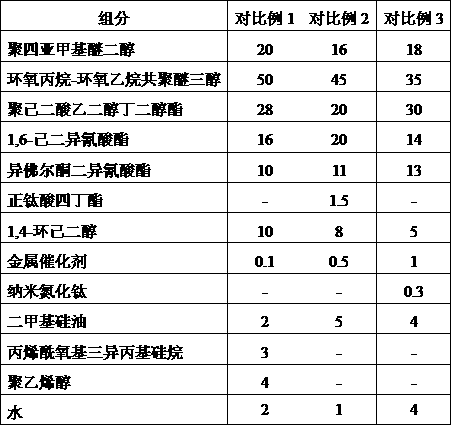

[0034] The raw material of the foam layer comprises the following components in parts by weight:

[0035] Table 1

[0036]

[0037] The weight average molecular weight of the polytetramethylene ether glycol is 250~2500, the weight average molecular weight of the propylene oxide-ethylene oxide copolyether triol is 1000~3500, and the polyethylene adipate The weight-average molecular weight of the alcohol butanediol ester is 500-3000; the metal catalyst is an organic bismuth catalyst and / or an organic tin catalyst.

[0038] The preparation method of described foam layer comprises the following steps:

[0039] S1. Mix 15~20 parts of polytetramethylene ether glycol, 35~50 parts of propy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com