Detection system for accurate position of rotor of large spliced arc motor and detection method of detection system

A rotor position detection and splicing technology, applied in electromechanical devices, control systems, control generators, etc., can solve the problem of inability to make hybrid photoelectric encoders, and achieve the effect of saving calculation speed, simple detection, and simplified calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

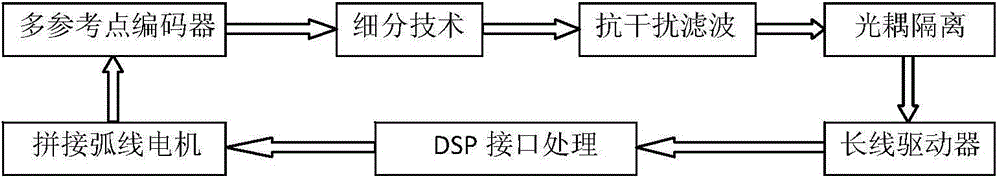

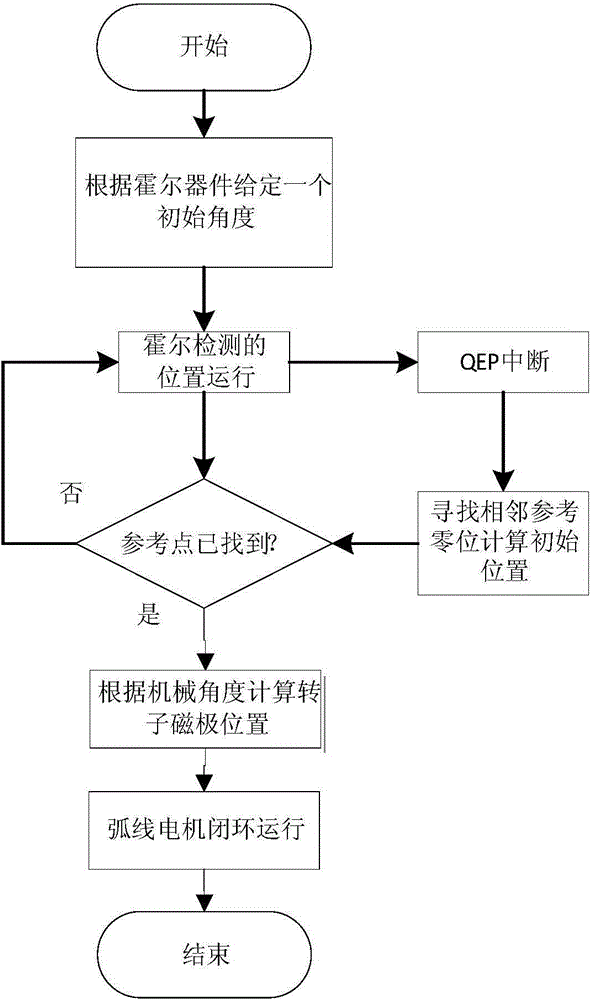

[0028]Embodiment 1, a detection system for the rotor magnetic pole position of a spliced arc motor for a large astronomical telescope. The spliced arc motor is a self-developed multi-pole permanent magnet synchronous motor. The present invention is designed to detect the rotor magnetic pole position of the spliced arc motor The system requires fast, simple and real-time detection of the rotor magnetic pole position of the permanent magnet synchronous motor. The vector control method is used to control the three-phase current amplitude and phase of the stator winding according to the precise position of the rotor magnetic pole measured in real time, so as to ensure the large-scale astronomical The telescope drive system runs smoothly.

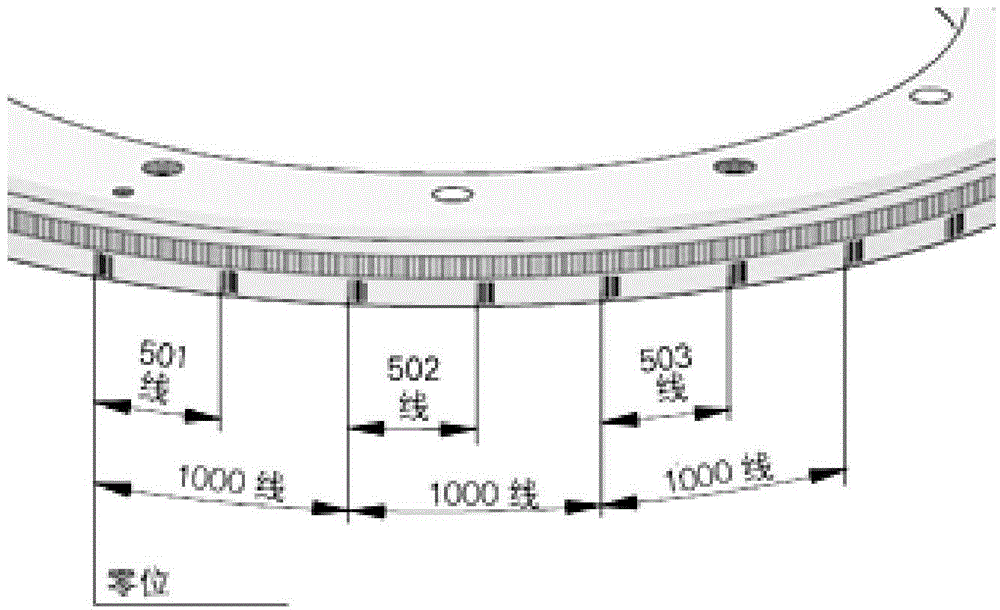

[0029] The system first subdivides and anti-interferences the incremental encoder signal with multiple reference points, and sends it to the encoder signal processing interface of the DSP, which is converted by the DSP into the precise posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com