Method for manufacturing pants-type absorbent articles

A manufacturing method and absorptive technology, which are applied in the fields of absorbent pads, medical science, clothing, etc., can solve the problems of large leak-proof sheets, unfavorable manufacturing costs, and high manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention relates to a method for manufacturing a pants-type absorbent article capable of efficiently and stably manufacturing a pants-type absorbent article that effectively prevents leakage from longitudinal ends of an absorbent main body at low cost.

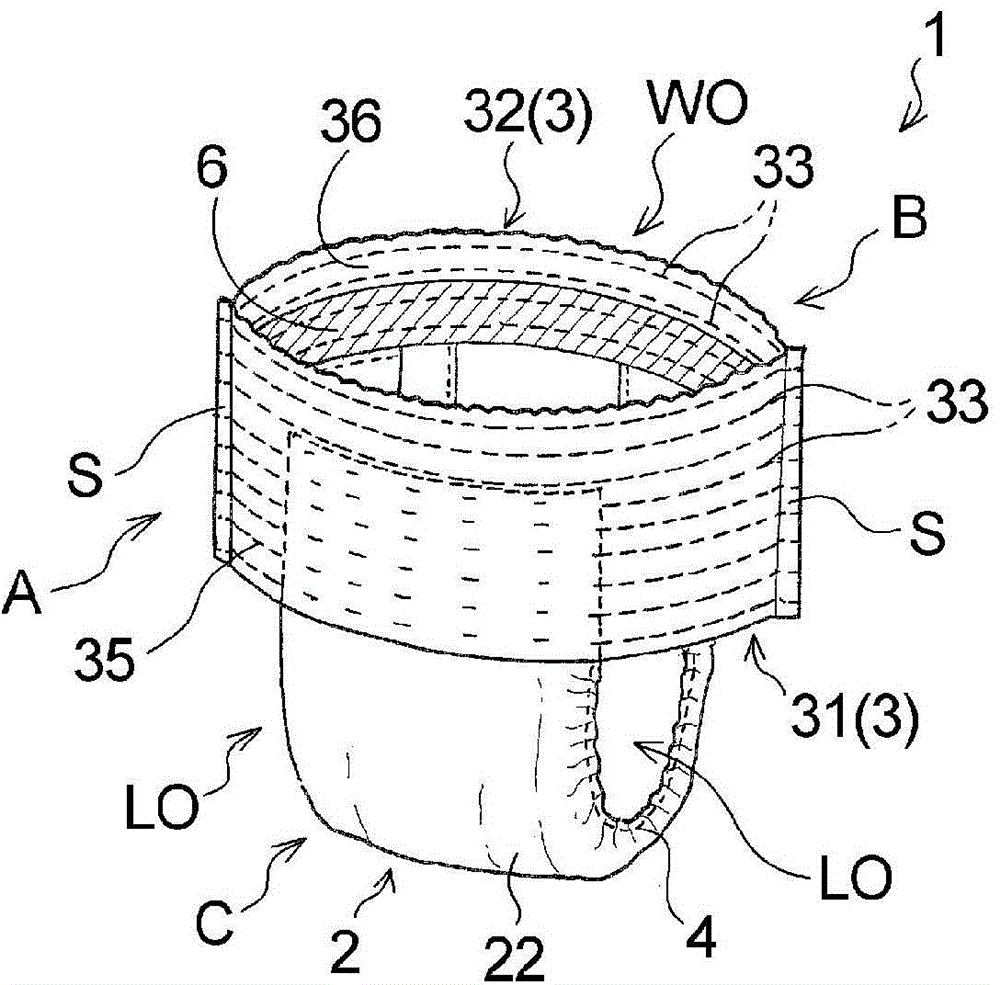

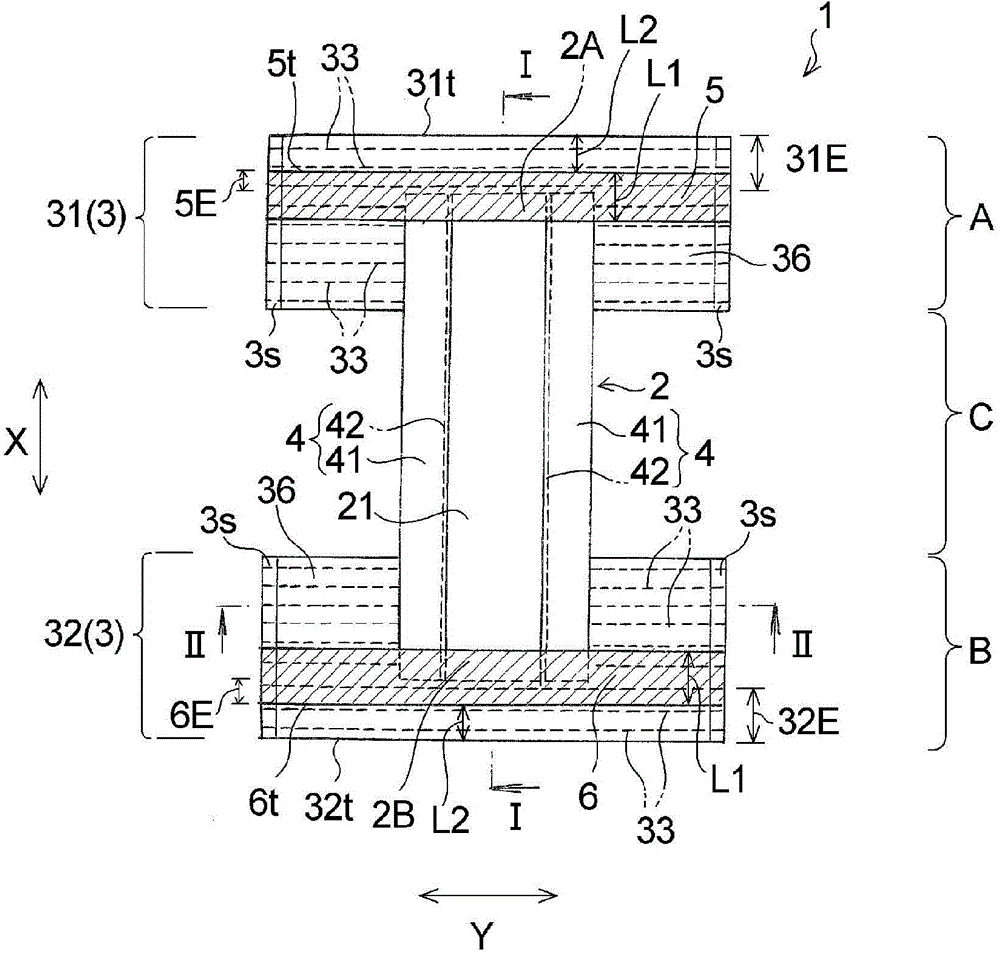

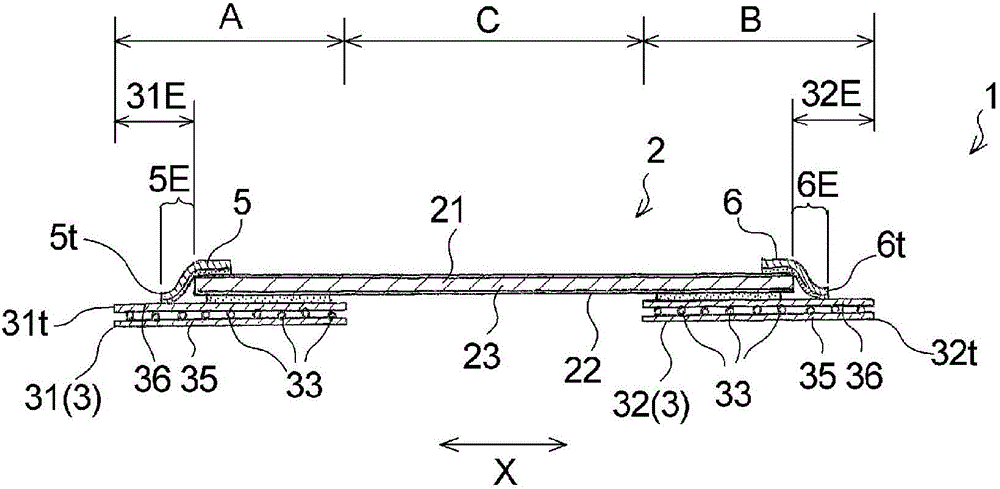

[0020] Hereinafter, first, the underpants-type absorbent article manufactured by carrying out the manufacturing method of the underpants-type absorbent article of this invention is demonstrated based on the underpants-type disposable diaper which is one preferable embodiment, referring drawings. Such as Figure 1 ~ Figure 4 As shown, the underpants-type disposable diaper 1 of this embodiment includes an absorbent main body 2 and an exterior body 3 arranged on the non-skin-facing side of the absorbent main body 2 to fix the absorbent main body 2, and has a The longitudinal direction X in the front-rear direction and the transverse direction Y perpendicular to it, and in the longitudinal direction X, there ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com