Automatic rice husking, milling and vending all-in-one machine

An all-in-one machine and grain husker technology, which is applied in grain milling, grain processing, grain pod removal, etc., can solve the problems of easy deterioration and pollution, high labor costs, secondary pollution of rice, etc., to prevent inaccurate weighing. , reduce production costs and ensure the effect of thoroughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

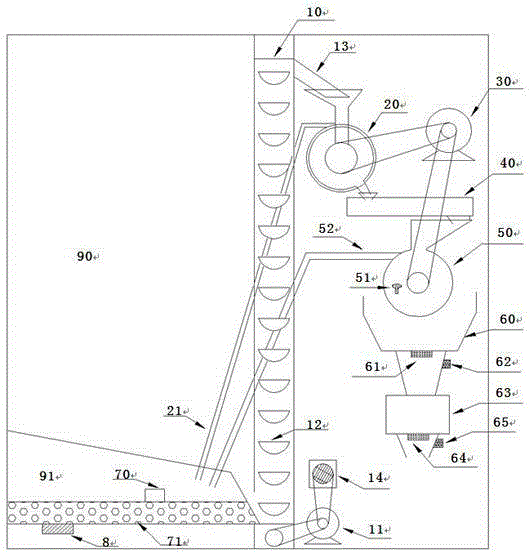

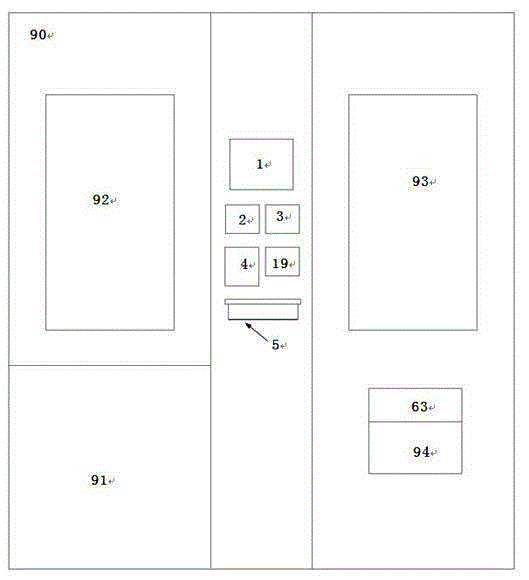

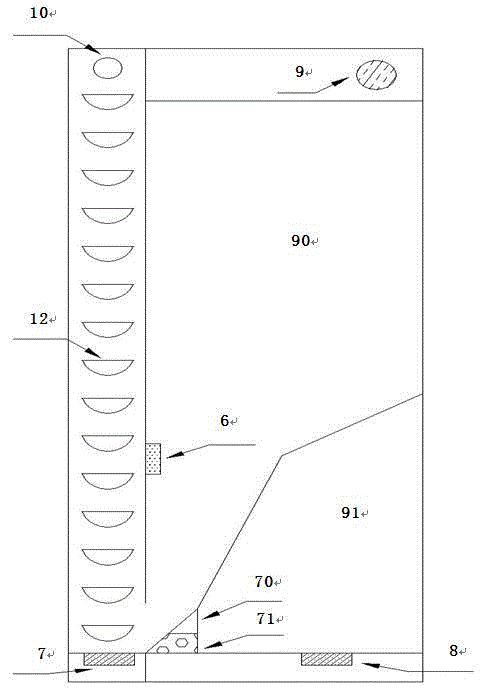

[0033] The technical solution of the present invention will now be described in detail in conjunction with the accompanying drawings. It should be understood that the following examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. Without departing from the spirit and essence of the present invention, any modifications or replacements made to the steps or conditions of the present invention belong to the scope of the present invention.

[0034] Unless otherwise specified, the technical means used in the embodiments are conventional means well known to those skilled in the art.

[0035] The product parameter of the present invention is as shown in the following table:

[0036] project parameter Processing capacity 150~220kg / hour Voltage 220V main motor 2200w, 1400 rpm Hoist power 250w, 1400 rpm barn volume 1000kg, 1.4 cubic Husk bran bin volume 300kg, 0.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com