A horizontal pulverizer for waste rubber

A waste rubber and pulverizer technology, applied in recycling technology, mechanical material recycling, plastic recycling, etc., can solve the problems of poor pulverization effect and failure of pulverized rubber to meet the requirements, and achieve good pulverization effect and high operating efficiency. , the effect of smashing effect enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in combination with specific embodiments.

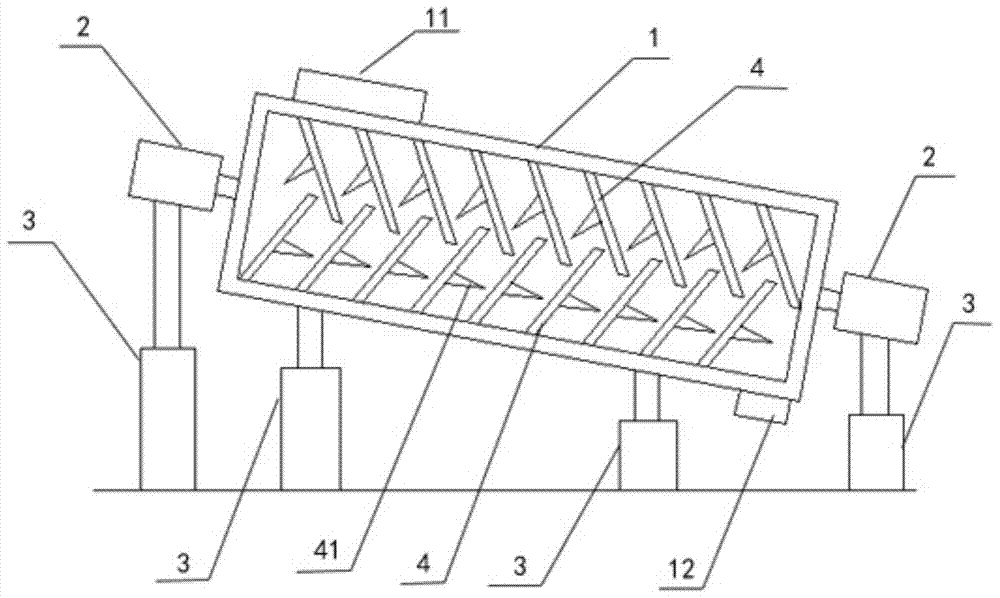

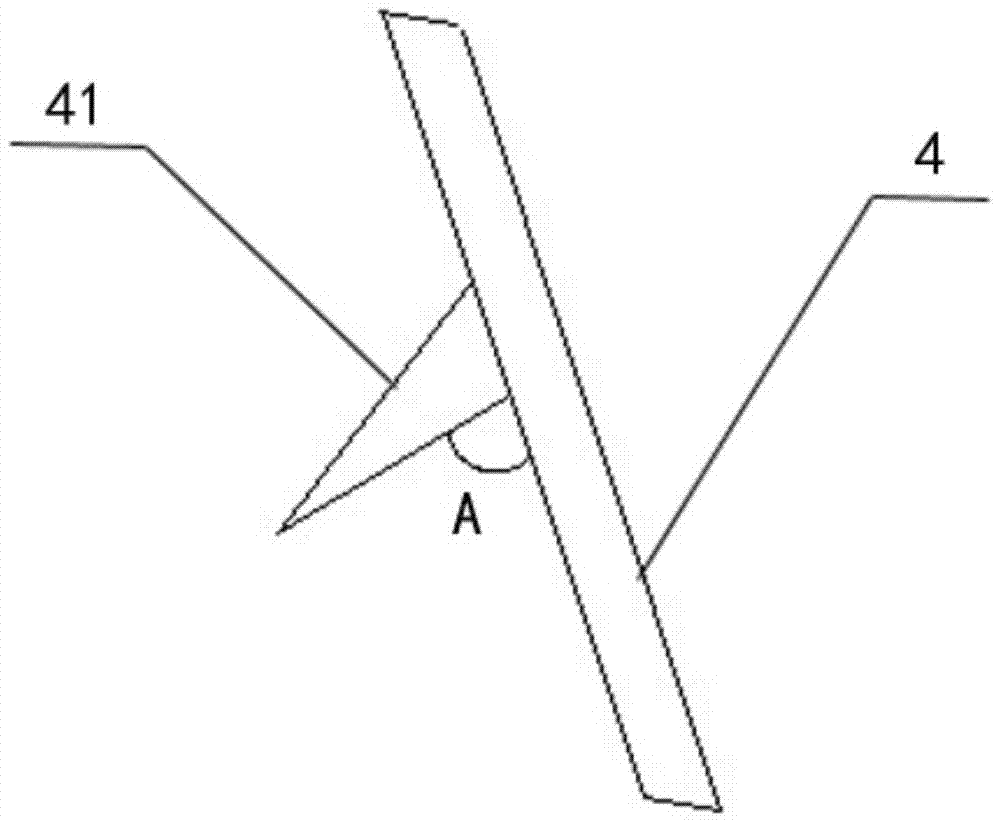

[0021] like figure 1 As shown, a horizontal pulverizer for waste rubber includes a pulverizer body 1, and the pulverizer body 1 is arranged in a horizontal structure. The upper end side of the pulverizer body 1 is provided with a waste rubber inlet 11 , and the lower end side is provided with a waste rubber outlet 12 . The pulverizer body 1 has a rectangular structure. Both sides of the pulverizer body 1 are respectively provided with motors 2 . The pulverizer body 1 is provided with a pulverizing blade 4 inside. The pulverizing blades 4 are distributed on the upper and lower inner walls of the pulverizer body 1; the pulverizing blades 4 and the upper and lower inner walls of the pulverizer body 1 are arranged obliquely. The ends of the pulverizing blades 4 on the upper inner wall of the pulverizer body 1 and the pulverizing blades 4 on the lower inner wall are distribu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com