A smart card bronzing module

A smart card bronzing module and card bronzing module technology, applied in gold powder printing, printing, rotary printing machines, etc., can solve problems such as large impact force on cards, card damage, deviation of card bronzing parts, etc., to avoid card damage due to pressure, reliable Sexual enhancement, card face beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

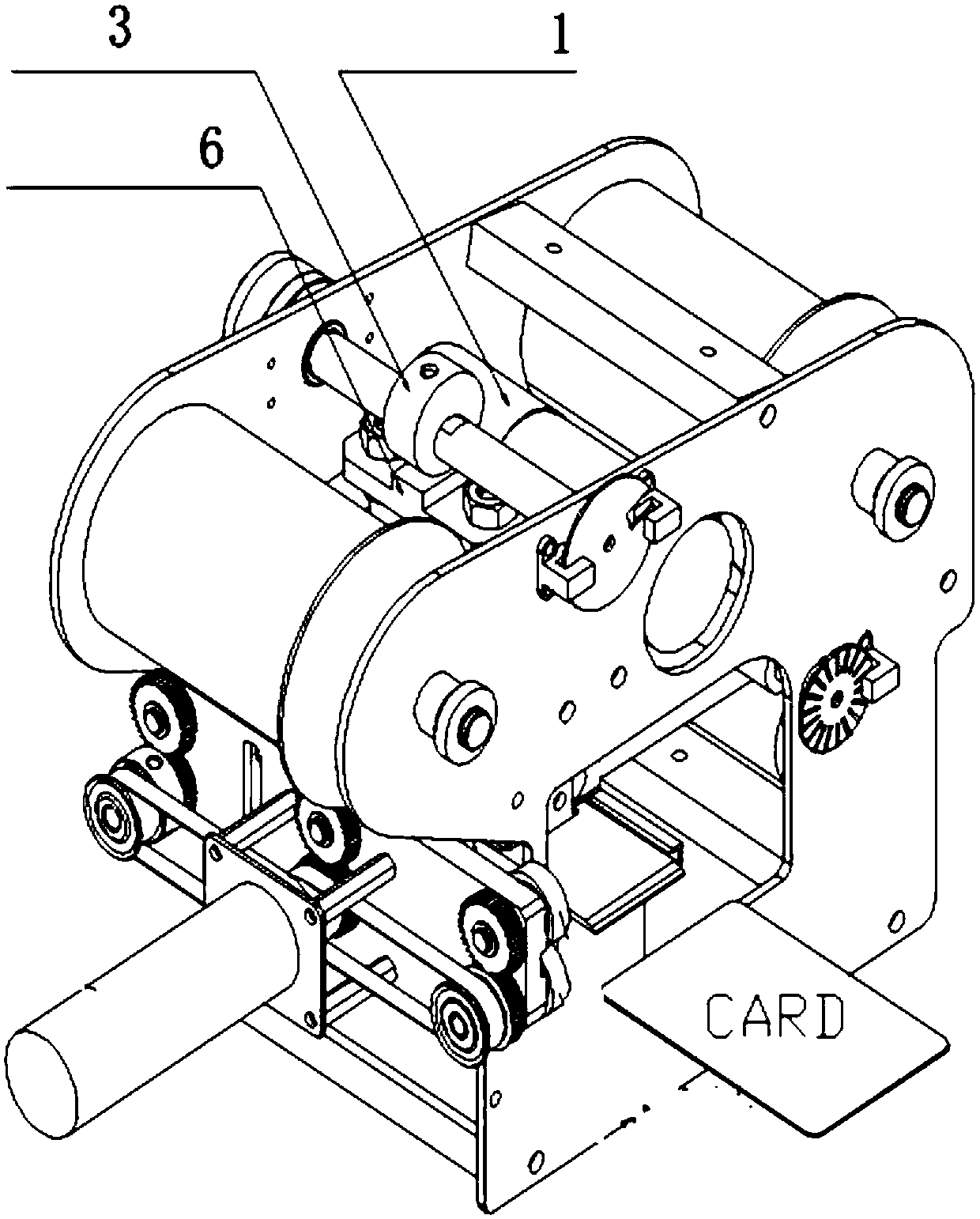

[0026] Such as figure 1 It is a three-dimensional view of the smart card hot stamping module. The cam pressing motor 1 is a DC motor, which is fixed on the inside of the two side mounting plates. The output shaft of the cam pressing motor 1 is provided with a synchronous wheel 2, a cam 3, and a camshaft One end is provided with a synchronous wheel 4, which forms a synchronous wheel group with the synchronous wheel 2, and the energy is transmitted by the synchronous belt 5.

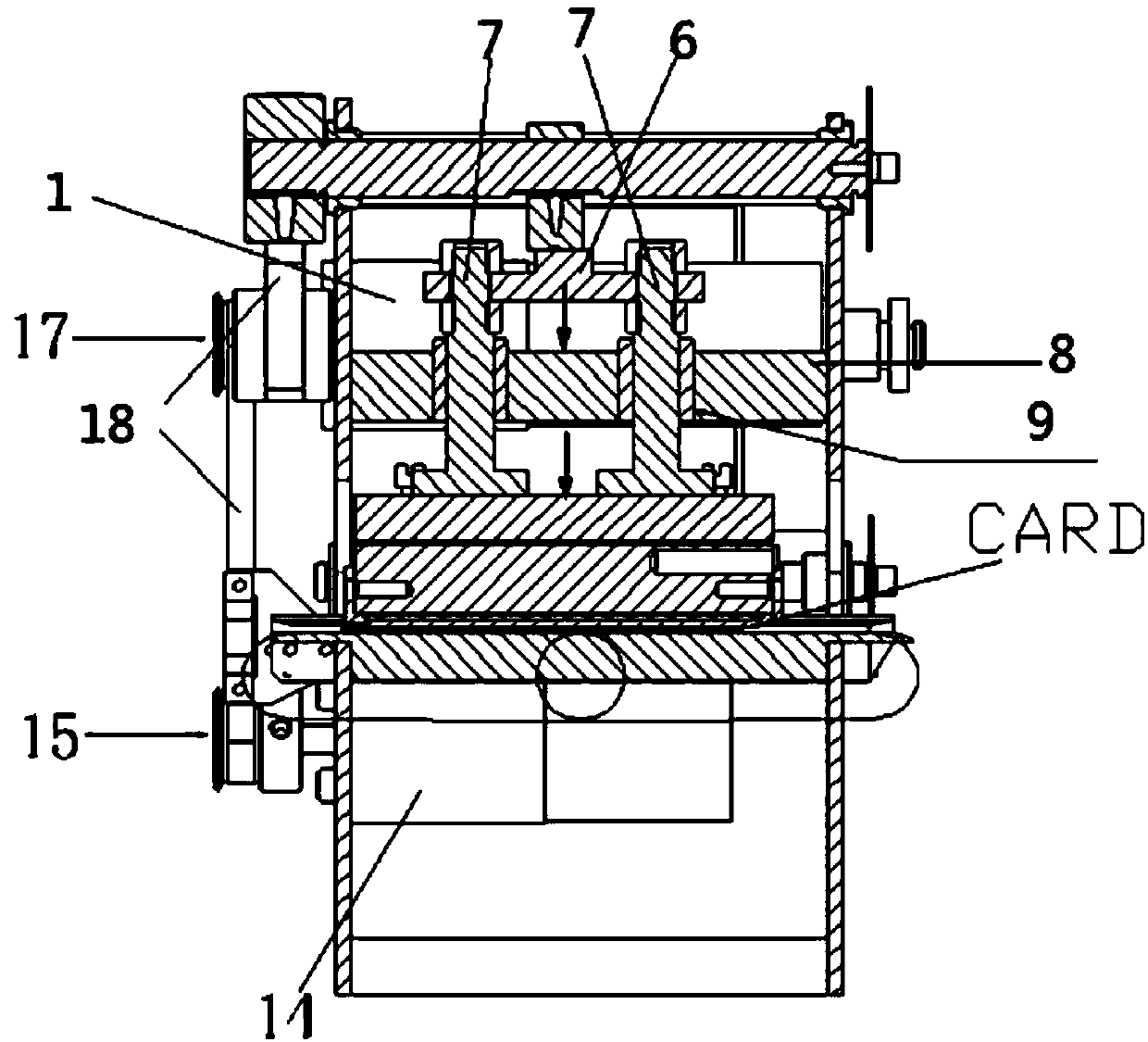

[0027] The synchronous wheel set drives the cam, extrudes the lower pressing rod cap 6, and then drives the lower pressing rod 7 to go down.

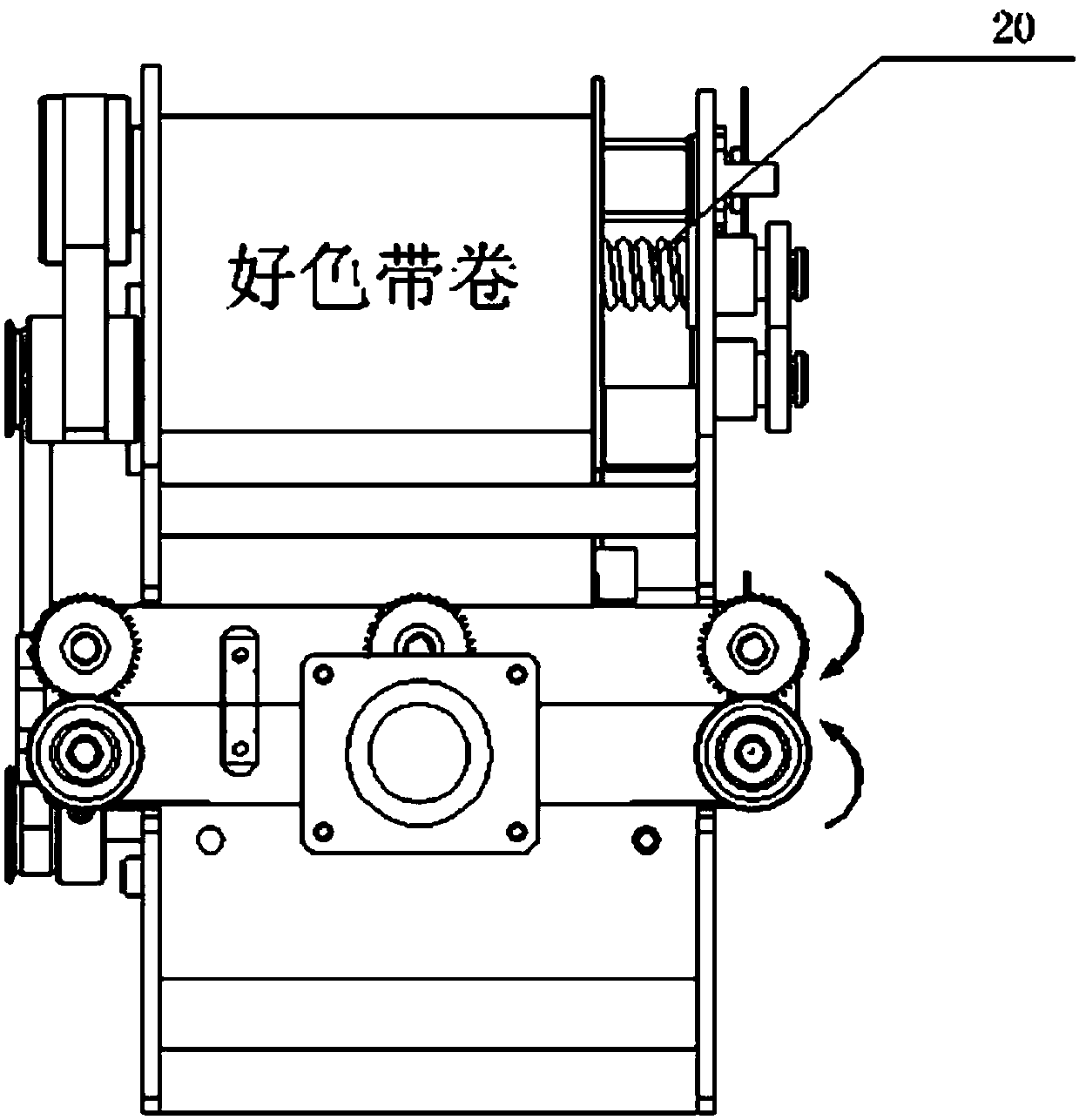

[0028] see Figure 2a-Figure 4 , the lower pressure rod cap, which is fixed on the upper ends of the two lower pressure rods, is in sliding contact with the lower pressure cam, and undertakes the lower pressure of the lower pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com