Special vehicle power system based on dual-end output work/traveling driving motor

A technology for driving motors and power systems, which is applied in electric vehicles, control drives, auxiliary drives, etc., can solve the problems of high power demand of the main drive motor, inconvenient layout of special vehicles, idle waste of operation motors, etc., so as to improve braking performance. Energy recovery rate, beneficial to reasonable layout, and the effect of avoiding idle waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

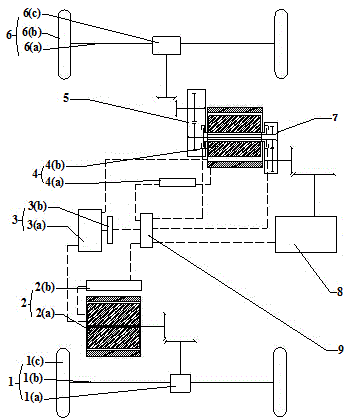

[0025] This embodiment discloses a special vehicle power system based on dual-terminal output operation / travel drive motors, including a vehicle controller 9, a main drive motor and its controller 2, an operation / travel drive motor and its controller 4, and a first clutch Transmission device 7, second clutch transmission device 5;

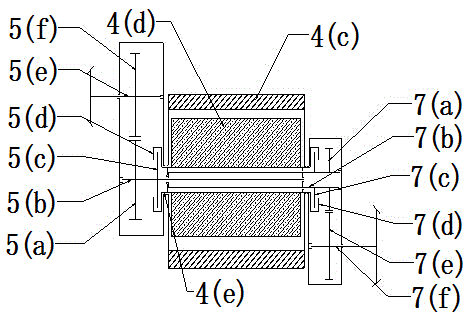

[0026] The working / travel driving motor 4(b) includes a stator 4(c), a rotor 4(d), and a rotor output shaft 4(e); the first clutch transmission device 7 includes a first clutch 7(c) , the first clutch input disc 7 (d), the first driving shaft 7 (b), the first driving shaft driving gear 7 (a), the first driven shaft 7 (f), the first driven shaft driven gear 7 (e); the second clutch transmission device 5 includes a second clutch 5 (c), a second clutch input disc 5 (d), a second driving shaft 5 (b), a second driving shaft driving gear 5 (a ), the second driven shaft 5 (e), the second driven shaft driven gear 5 (f);

[0027] The working / travel drivin...

Embodiment 2

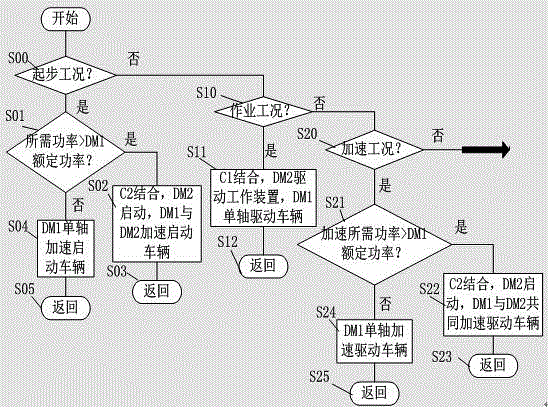

[0030] This embodiment discloses a special-purpose vehicle power system control strategy based on double-terminal output motors. The vehicle controller 9 in the power system controls the coordinated work of the entire power system, and can judge and select the appropriate one according to the working conditions of the vehicle. The driving mode control strategy, the driving mode of the special vehicle includes the main driving motor 2(a) single motor driving mode, the main driving motor 2(a) single braking mode, the working mode, the main driving motor 2(a) and the working motor 4( b) Timely four-wheel drive mode, combined braking mode of the main drive motor 2(a) and the working motor 4(b), the power system control strategy steps are as follows:

[0031] (1) The power control system first judges the mode signal of the special vehicle working condition, and the vehicle controller 9 judges whether it is the starting working condition according to the key position signal, the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com