Compositions comprising tetrafluoropropene and difluoromethane and uses thereof

A technology of difluoromethane and tetrafluoropropene, which is applied in the field of compositions containing tetrafluoropropene and difluoromethane and its application, and can solve problems such as low energy efficiency, toxicity, and flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0138] cooling performance

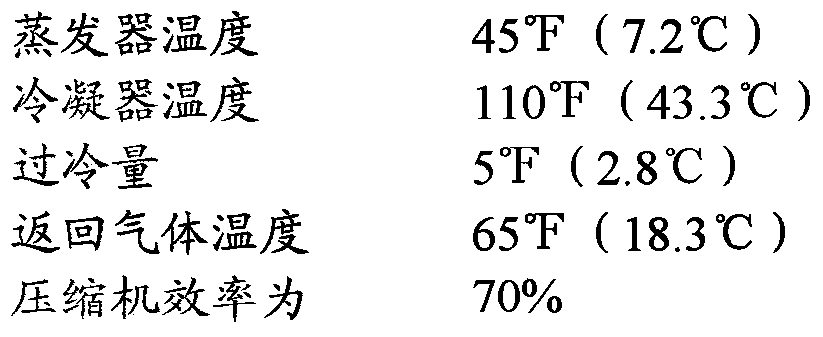

[0139] The cooling performance of compositions comprising HFO-1234yf and HFC-32 was determined and is shown in Table 1, compared to R410A (for a refrigerant blend comprising 50% by weight HFC-32 and 50% by weight HFC-125 ASHRAE designation) for comparison. Pressure, discharge temperature, COP (energy efficiency) and cooling capacity (cap) are calculated from physical properties measured for the following specific conditions (as typical for air conditioners):

[0140]

[0141] Note that superheat is included in cooling capacity.

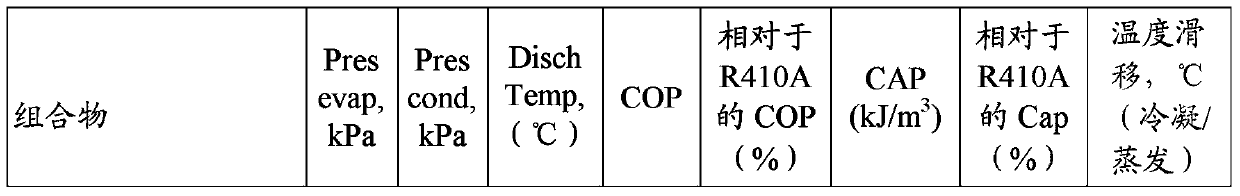

[0142] Table 1

[0143]

[0144]

[0145] These data show that certain compositions of the invention will serve as good replacements for R410A and even provide improvements over pure HFC-32. Of note are compositions ranging from 20% to 55% by weight of HFO-1234yf and 80% to 45% by weight of HFC-32 that provide a cooling capacity of ±20% for R410a, Improved energy efficiency (COP) and low temperature glide ...

Embodiment 2

[0147] heating performance

[0148] Table 2 shows the performance of certain exemplary compositions compared to HFC-134a, HFO-1234yf and R410A under typical heat pump conditions. In Table 2, Evap Press is the evaporator pressure, Cond Pres is the condenser pressure, Comp Disch T is the compressor discharge temperature, COP is the coefficient of performance (similar to energy efficiency), and CAP is the capacity. Calculated data are based on measured physical properties and the specific conditions listed below.

[0149]

[0150] Table 2

[0151]

[0152] These data show that these compositions are useful as R410A replacements in heat pump applications. Specifically, compositions ranging from about 25 wt. % to about 60 wt. % HFO-1234yf and about 75 wt. % to about 40 wt. Power efficiency (COP) and an average temperature glide of less than about 5°C. Furthermore, a composition with 78.5 wt% HFO-1234yf and 21.5 wt% HFC-32 provides significantly improved heat capacity ...

Embodiment 3

[0154] flammability

[0155] Flammable compounds can be identified by testing according to ASTM (American Society for Testing and Materials) E681-2004, using an electronic ignition source. Such flammability tests were performed on compositions of the present disclosure in air at 101 kPa (14.7 psia), 50% relative humidity, and at 23°C and 100°C, and at various concentrations in order to determine the lower flammability limit (LFL). The results are shown in Table 3.

[0156] table 3

[0157]

[0158] Since the LFL is greater than 10% by volume, these data demonstrate that compositions comprising HFO-1234yf and HFC-32 with less than 45% by weight HFO-1234yf can be classified as non-flammable in Japan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com