A device for removing yarn hairiness with precise direction and selective selection

A selective, yarn technology for heating/cooling fabrics, textiles and paper, fabric surface trimming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

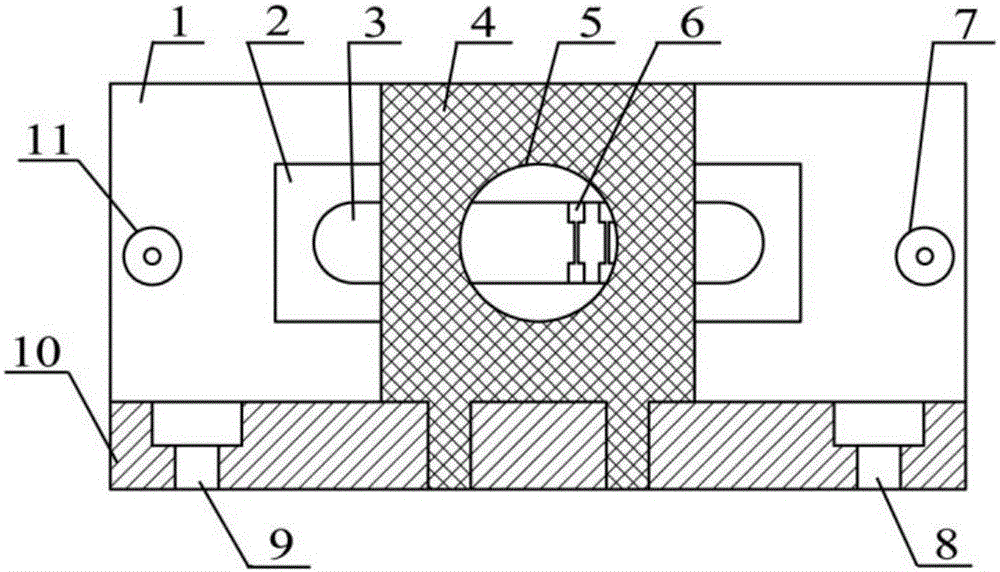

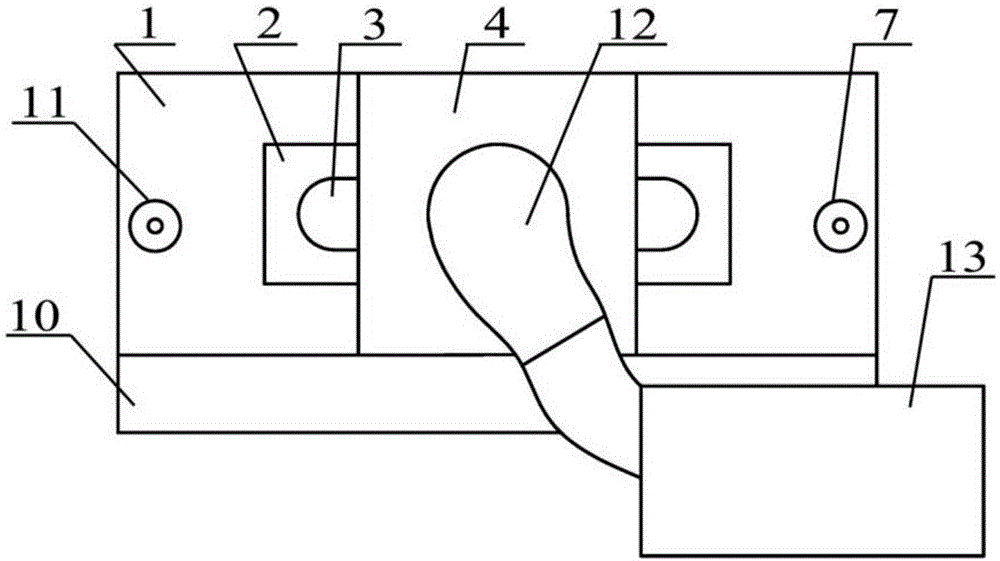

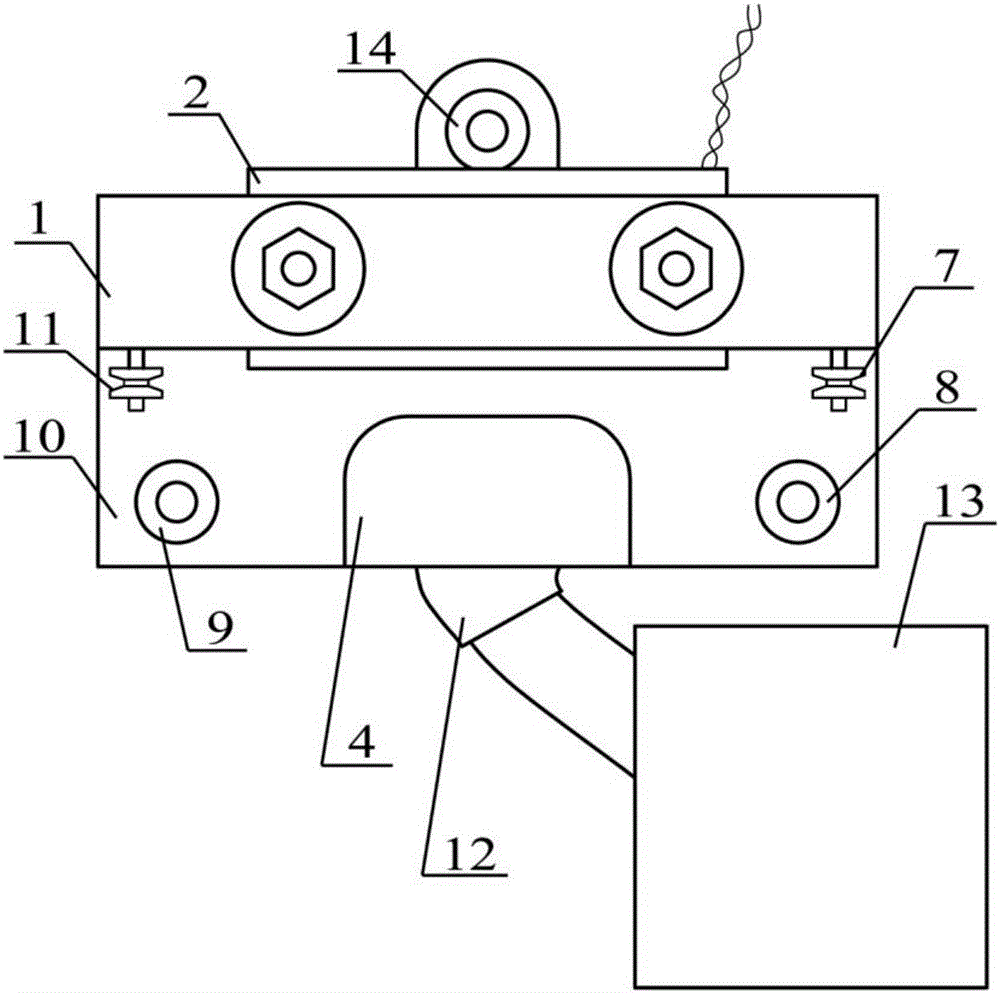

[0017] The following is a further detailed description of a device for removing hairiness of a yarn with precise orientation and selection in conjunction with the accompanying drawings.

[0018] see Attachment.

[0019]Directional, precise and selective yarn hairiness removal device consists of a base plate 10, a yarn guide, a singeing device, and a directional blowing device. The base plate 10 is provided with a first fixing hole 8, a second fixing hole 9, and a third fixing hole 14. , the first fixing hole 8, the second fixing hole 9, and the third fixing hole 14 are arranged in an equilateral triangle on the base plate 10, and the wire guide is composed of a fixing plate 1, a first wire guide wheel 11, and a second wire guide wheel 7. The working surface of the plate 1 is rectangular, and the middle part of the working surface of the fixed plate 1 is provided with a rectangular through groove. The fixed plate 1 is vertically fixed and installed on the base plate 10. Betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com