Double-speed driving wheel

A transmission wheel and transmission shaft technology, which is applied to transmission elements, transmission parts, multi-transmission ratio transmissions, etc. Solve the problem of bearing installation, solve the problem of motion balance, and the effect of small overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

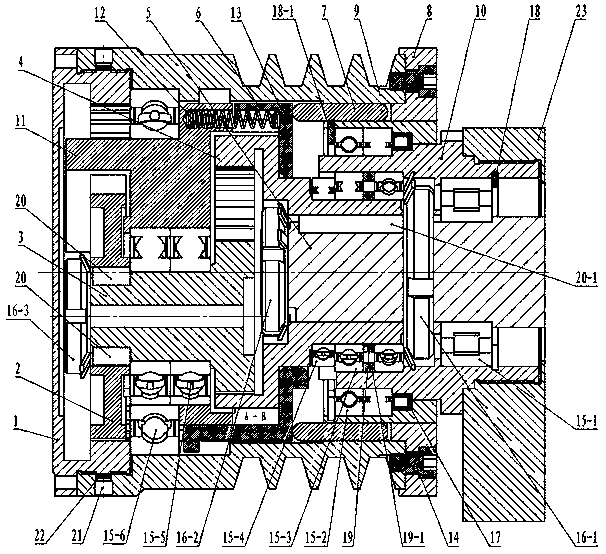

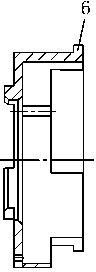

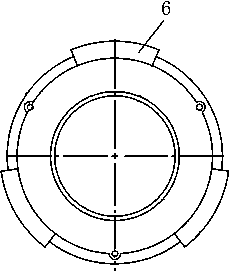

[0025] like Figure 1 to Figure 7 As shown, this embodiment includes: the inner gear of the end cover is the first internal gear 1; the transmission external gear is the first external gear 2; the transmission pinion is the second internal gear 3; the output internal gear is the second external gear 4; the output Shaft 5; two-way three-jaw mobile clutch also called multi-jaw clutch block 6; movable ejector rod 7; concave-convex speed-regulating plate 8; transmission wheel 9; fixed bearing seat 10; eccentric balance bearing seat 11; clutch spring is elastic Part 12; spring positioning pin 13; positioning screw pin 14; bearings 15-1, 15-2, 15-3, 15-4, 15-5, 15-6; locking round nuts and stop washers 16-1, 16-2, 16-3; Skeleton oil seal 17; Elastic bearing rings 18-1, 18-2 for holes; Bearing bushings 19, 19-1; Flat keys 20, 20-1; ; Copper pad 22 ;

[0026] Transmission wheel 9, used for input or output speed;

[0027] Gear set, used for transmission wheel speed change;

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com