Packer performance detection device

A detection device and packer technology, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of great differences in test results, simple packer performance testing devices, cumbersome and one-sided testing procedures, etc. , to achieve the effect of low maintenance cost, convenient storage and maintenance, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

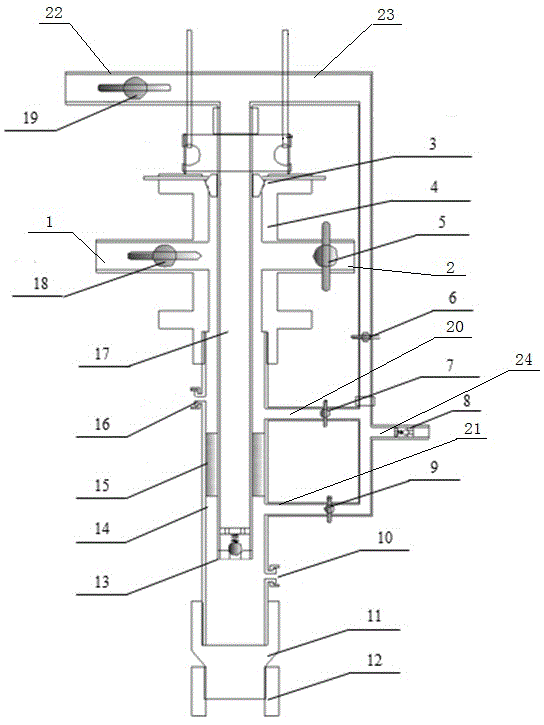

[0023] Such as figure 1 As shown, the present invention provides a packer performance testing device, which includes a casing 14, the bottom end of which is fixed on the base 12 through a blind plug 11, and a tubing 17 is suspended inside the casing 14 through a tubing hanger 3, The lower end of the tubing 17 is connected with a packer 15 coaxial with the tubing 17, the bottom end of the packer 15 is connected with a ball seat 13, the upper end of the casing 14 is provided with a wellhead cross 4, and the first wellhead cross 4 is set. The first through pipe 1 and the second through pipe 2 are respectively perpendicular to the central axis of the casing 14, and the first through pipe 1 is provided with a first cement truck interface gate valve 18 for connecting the cement truck, and the second through pipe 2 is provided with a On the second cement truck interface gate valve 5 connected to the cement truck, a first high-pressure pipeline 20 and a second high-pressure pipeline 2...

Embodiment 2

[0037]On the basis of Embodiment 1, in order to increase the flow and velocity of the high-pressure liquid passing through the third high-pressure pipeline 22 and the fourth high-pressure pipeline 23 , the third high-pressure pipeline 22 and the fourth high-pressure pipeline 23 are communicated.

Embodiment 3

[0039] On the basis of Embodiment 1, in order to facilitate the observation of the leakage situation, especially the leakage situation when the pressure is tested, the lower observation port 10 is located on the pipe wall of the casing 14 between the ball seat 13 and the blind plug 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com