Asynchronous motor parameter offline identification method

A technology for asynchronous motors and identification methods, which is applied in the direction of AC motor control, electrical components, control systems, etc., can solve the problems of low identification accuracy, complicated operation process, and error of identification results, and achieve high identification accuracy, simple identification method, The effect of small identification error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

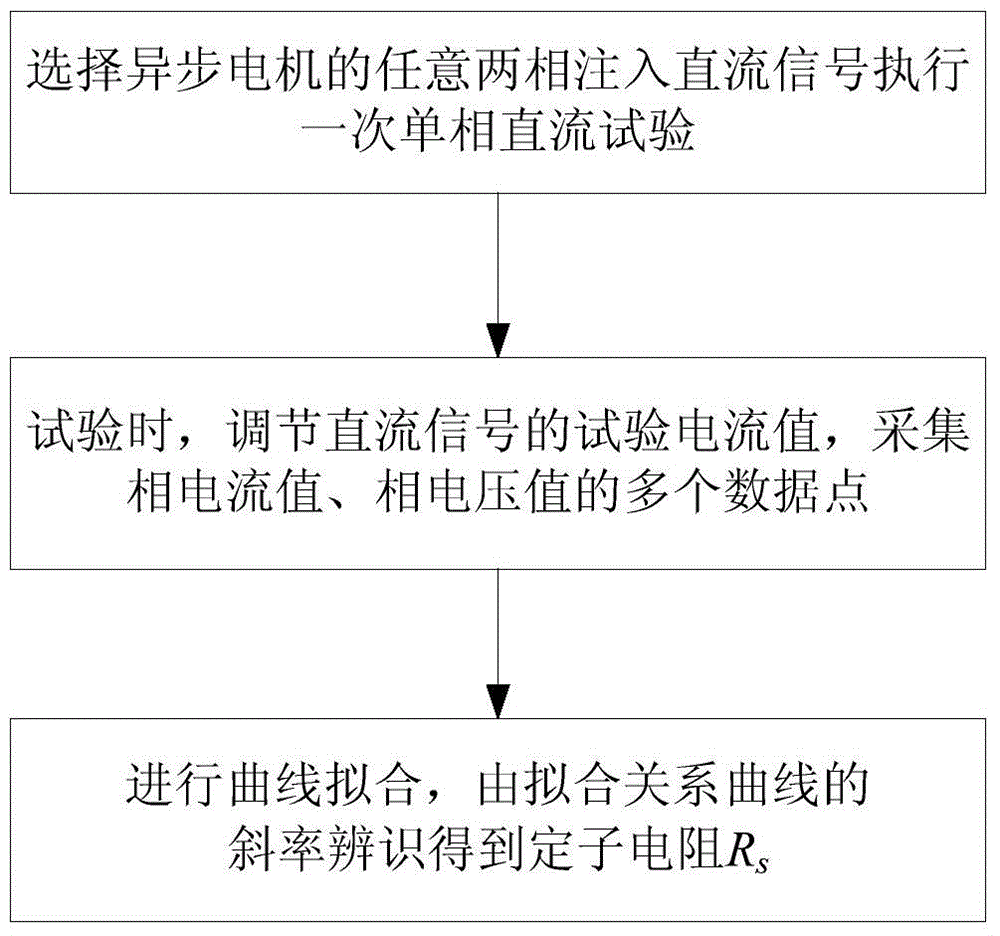

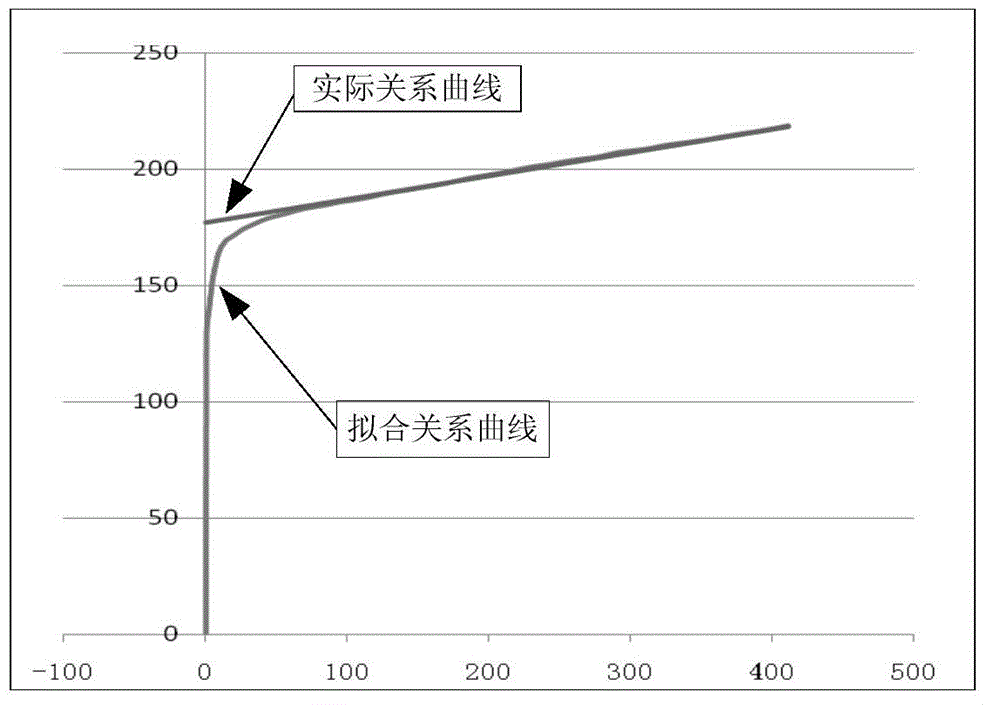

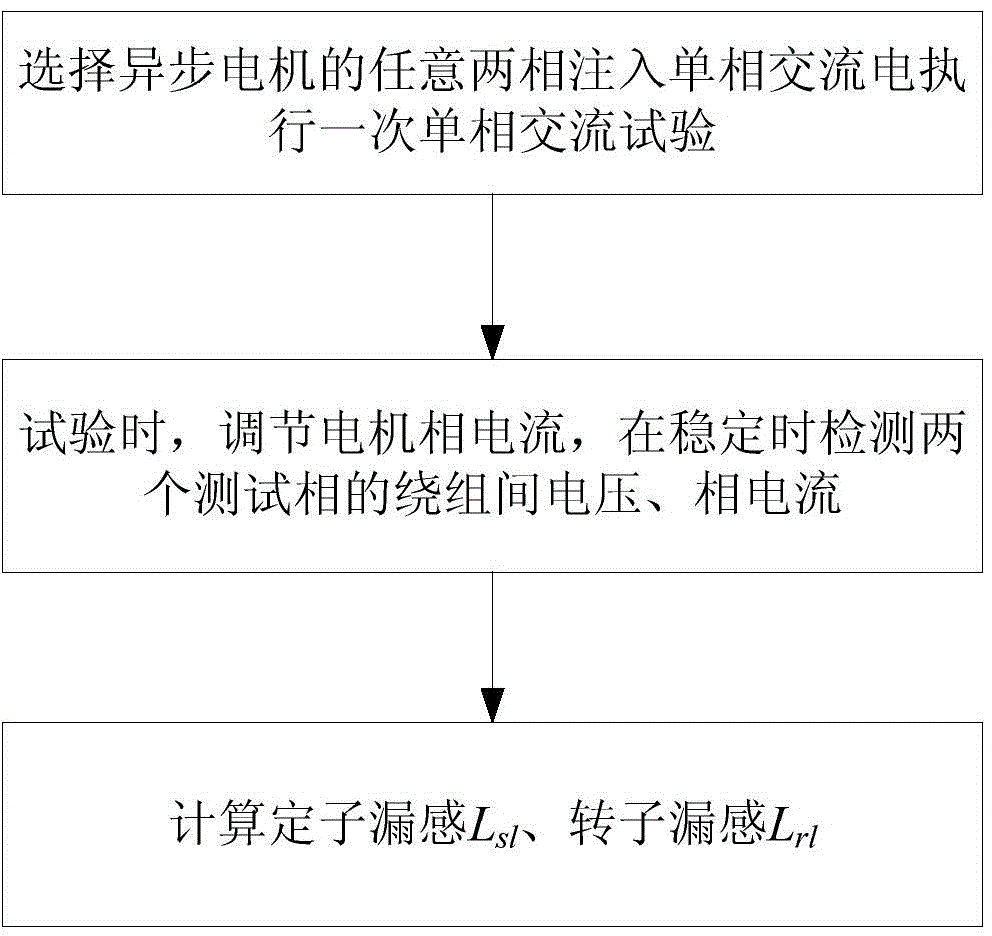

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

[0048] In this embodiment, the asynchronous motor is in a static state, and the wiring mode of the inverter output to the motor remains unchanged. In the data analysis process, the voltage reconstructed by the modulation voltage of the inverter for control is used. The modulation voltage of the inverter is based on the DC voltage The reconstructed voltage does not need to consider the skin effect and dead zone compensation, and does not require an additional voltage sampling device or equipment to collect voltage from the inverter; in addition, the inverter output current is sampled using the built-in inverter The current sampling of at least one phase is realized, and there is no need to add additional current sampling equipment to collect current.

[0049] 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com