High-efficient low-cost electromagnetic shielding film and manufacturing method thereof

A technology of electromagnetic shielding film and manufacturing method, applied in the fields of magnetic field/electric field shielding, chemical instruments and methods, electrical components, etc., can solve the problems of high cost of electromagnetic shielding film, insufficient product market competitiveness, affecting the price of electronic products, etc. , to meet the special use requirements, shorten the processing process, and achieve the effect of excellent conduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

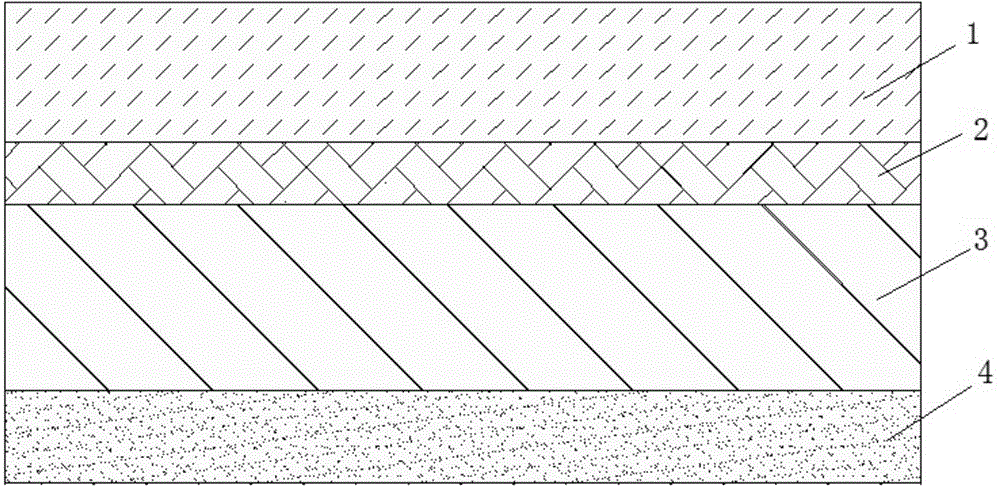

[0039] The "four-layer electromagnetic shielding film" of this embodiment has the characteristics of low cost and high efficiency, and its structure is as follows figure 1 As shown, it includes: a carrier film layer 1, an ink layer 2 coated on the carrier film layer 1, and a conductive adhesive layer 3 coated on the ink layer 2, and the conductive adhesive layer 3 is also thermally pressed. A layer of release film 4 is combined.

[0040] The carrier film layer 1 is a high-temperature-resistant carrier, which is a high-molecular polymer film. It mainly acts as a lamination protection and a carrier for the ink layer 2. Specifically, it can be one or more modifications of PET, PEN, PI, PBT and PPS films. Thin film with a thickness of 25-200μm.

[0041] The ink layer 2 can be one or a mixture of epoxy resin, polyacrylic resin, rubber elastomer, phenolic resin, polyester resin and polyurethane resin, with a thickness of 5-50 μm. At the same time, the ink layer 2 also contains fun...

Embodiment 2

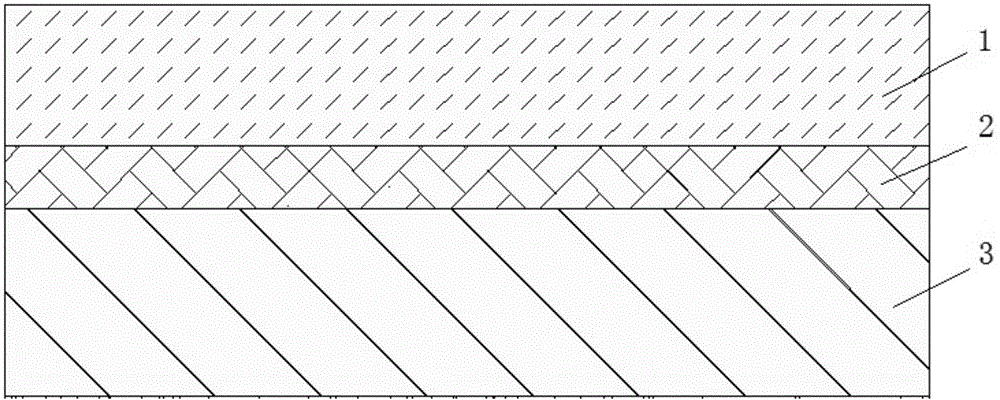

[0060] The electromagnetic shielding film of this embodiment has a three-layer structure. Compared with Embodiment 1, the difference is that the release film layer 4 is removed, which can further reduce product costs without affecting product performance. The manufacturing method includes the following step:

[0061] C-1. Use a micro-adhesive wheel to remove foreign particles on the inner surface of the carrier film roll;

[0062] C-2. Coating the prepared ink layer 2 on the inner surface of the carrier film roll;

[0063] C-3. The ink layer 2 is dried in a coating oven. The temperature of the coating oven is set at 80-180°C, and the line speed is set at 5-30m / min;

[0064] C-4. Then coat a layer of conductive adhesive layer 3 on the surface of the ink layer 2, and dry it in a coating oven. The temperature of the coating oven is set at 30-100°C, and the line speed is set at 5-30m / min;

[0065] C-5, harvest volume.

[0066] In summary, the electromagnetic shielding film of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com