Ridge and ridge side comprehensive soil-loosing and weeding operation machine

A technology of operating machines and ridges, which is applied to agricultural machinery and tools, agriculture, shovels, etc., can solve the problems of not having the function and effect of loosening soil, the decrease of soil moisture content, and the loss of water in ridges, so as to reduce the evaporation of soil water , High operating efficiency and good operating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

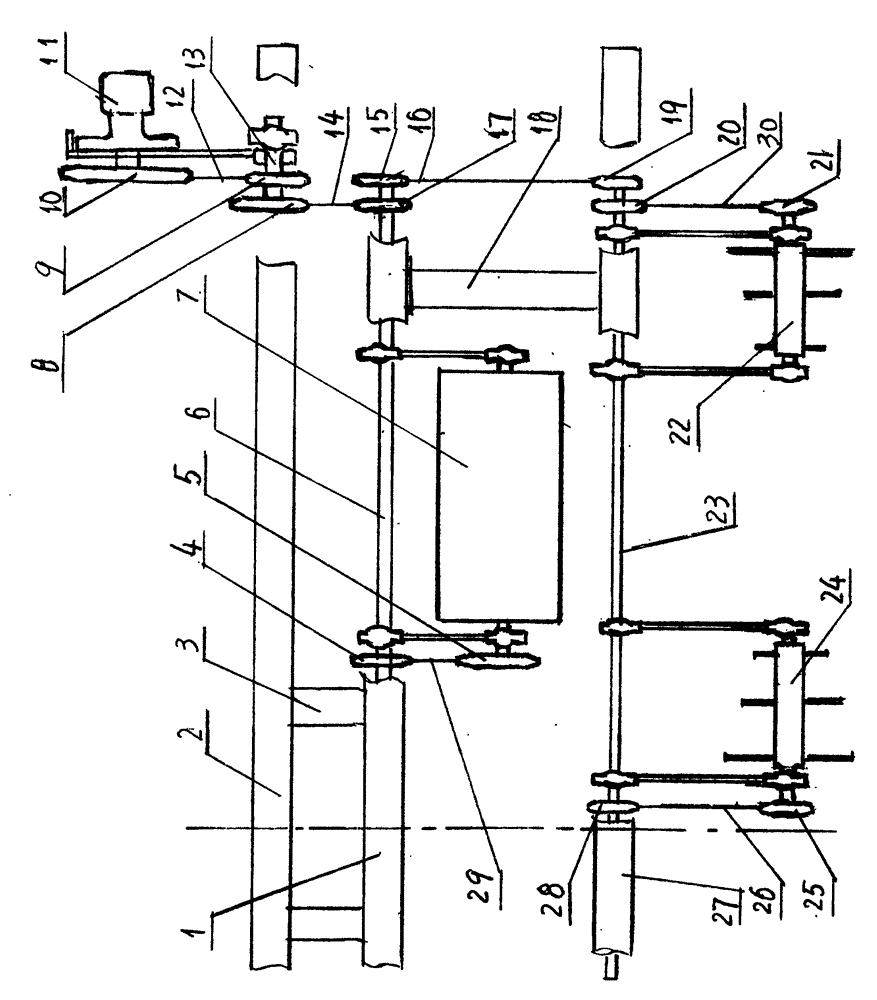

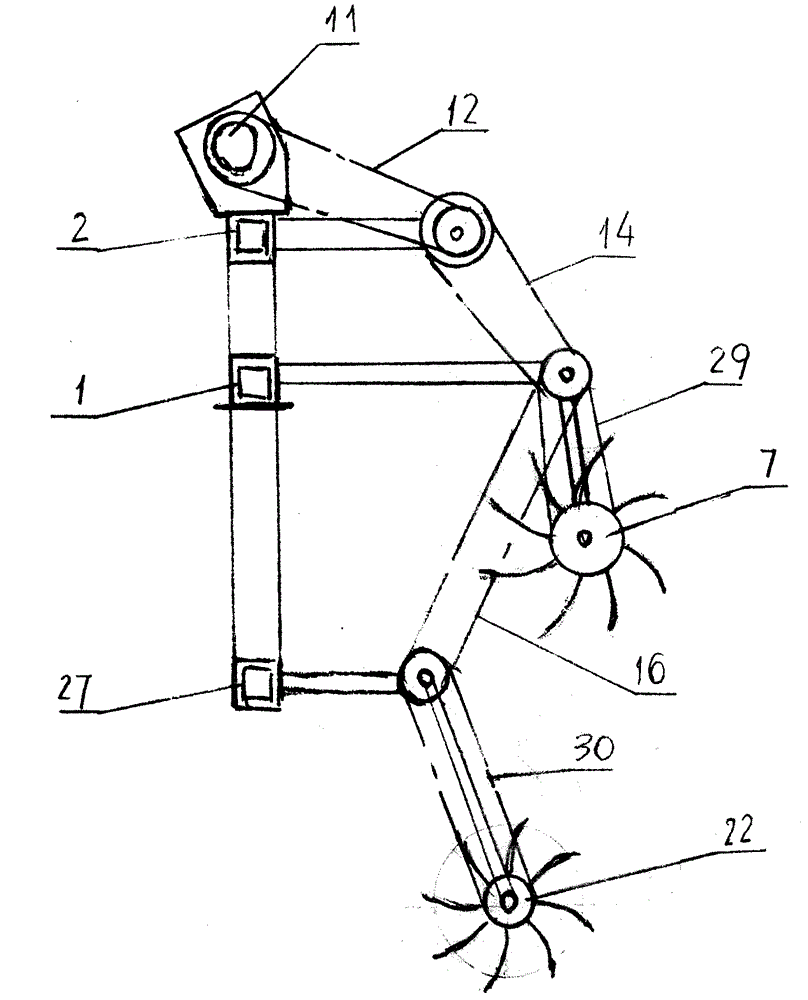

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A machine for loosening soil and weeding on ridges, ridges and sides. On the rear side of the front beam 2, the middle beam 1 is fixed and parallel to each other through the front longitudinal beam 3, and a hydraulic motor or a gear transmission box 11 is installed on the front beam 2. and the first drive shaft 13, the second drive shaft 6 is installed on the center beam 1, the first sprocket 10 is fixed on the power output shaft of the hydraulic motor or the gear transmission box 11, and the first drive shaft 13 is sequentially The second sprocket 9 and the third sprocket 8 are fixed, the fourth sprocket 17 and the fifth sprocket 4 are fixed on the second drive shaft 6, and the ridge platform loosening and weeding gear roller of the sixth sprocket 5 is equipped 7 Hanging installation on the second drive shaft 6, set the first transmission chain 12 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com