Extinguishing system for performing blind-spot-free dry powder spraying on large storage tank

A large-scale storage tank and dry powder fire extinguishing technology, which is applied in fire rescue and other fields, can solve the problems of limited chemical release rate, delayed effective time for extinguishing storage tank fires, and instant suffocation of fire sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

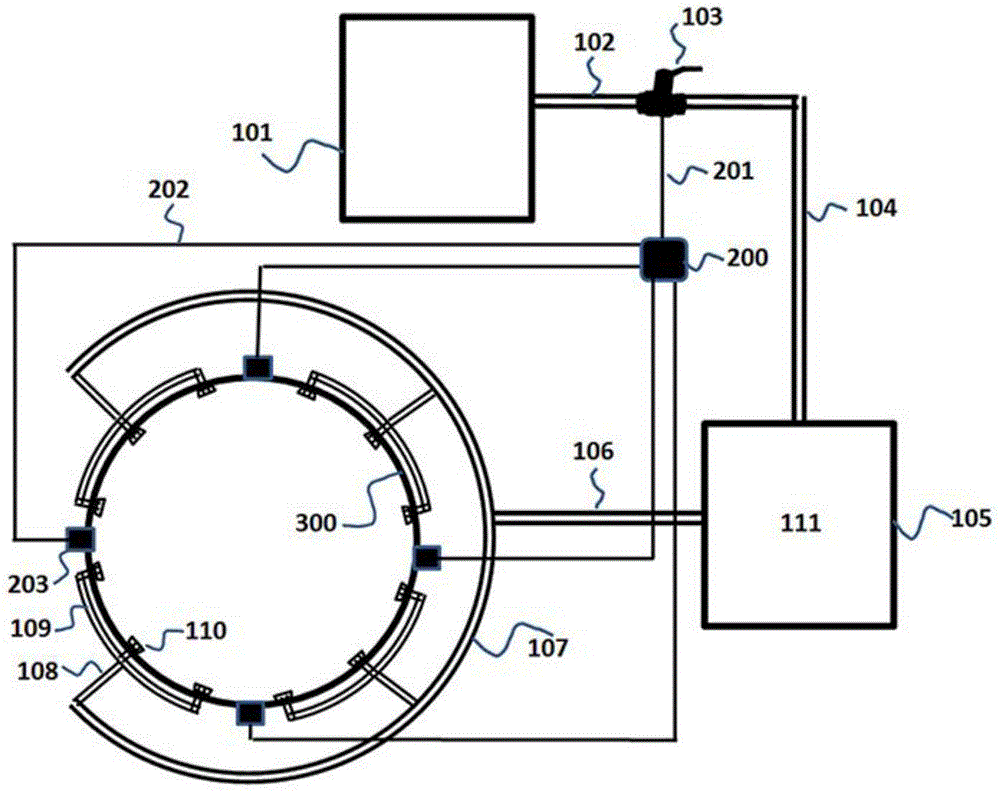

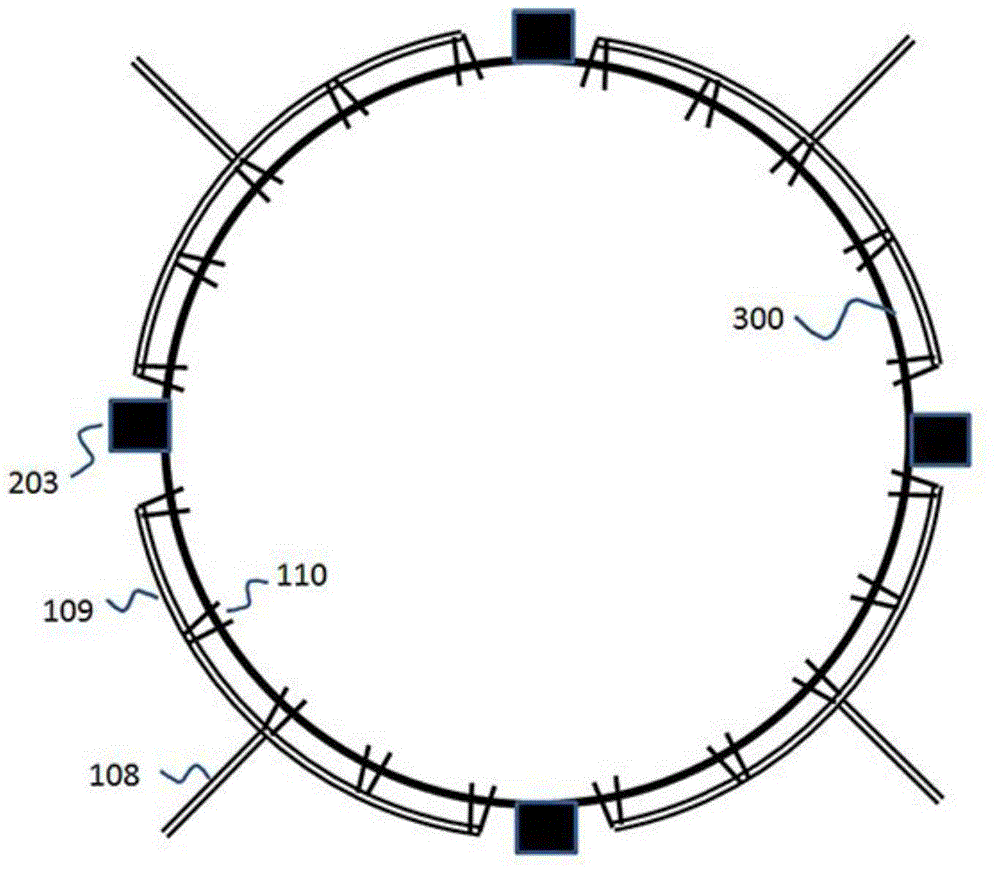

[0021] Example 1, such as figure 1 As shown, the driving medium (101) is nitrogen, the fire extinguishing agent storage tank (111) is ultrafine dry powder fire extinguishing agent, the control valve (103) is a nitrogen cylinder valve, and the driving medium delivery pipeline (102) is a nitrogen delivery pipeline. The agent delivery pipeline (106), (107), (108), (109) is the ultrafine dry powder fire extinguishing agent delivery pipeline. When a fire occurs in the protected storage tank, the temperature sensing device (203) detects the fire, sends a signal to the temperature sensing controller (200), opens and controls the nitrogen cylinder valve (103) to release nitrogen (101) and passes through the nitrogen delivery pipe Road (104) enters the superfine dry powder fire extinguishing agent storage tank (105), and the dry powder fire extinguishing agent (111) is released instantly through the ultrafine dry powder fire extinguishing agent delivery pipeline (106), (107), (108), (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com