Welding smoke purifier

A welding fume and purifier technology, which is applied in the field of purifiers, can solve the problems of poor purification effect and low fume purification efficiency, and achieve the effects of improving purification effect, preventing fire and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

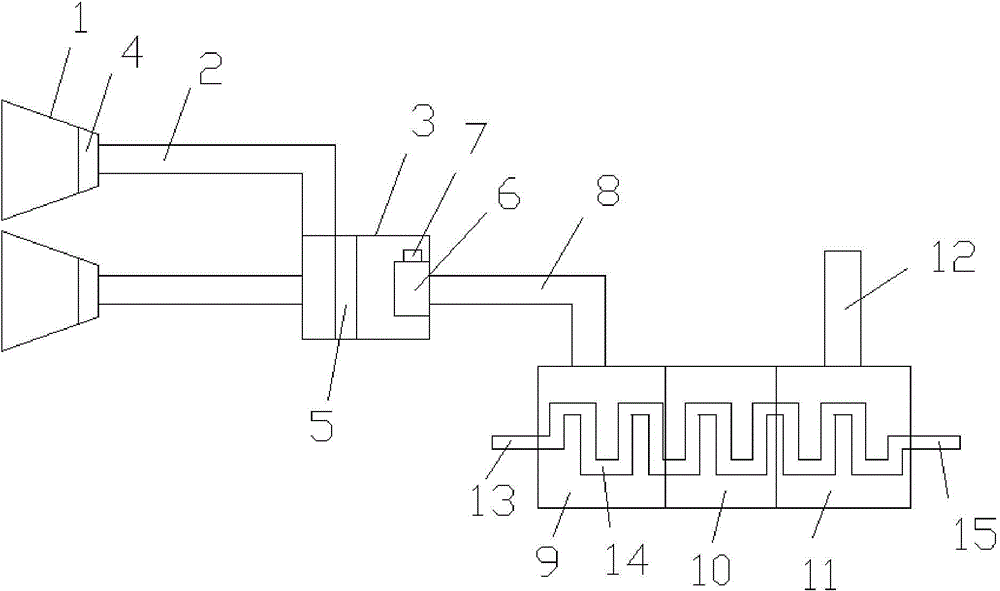

[0014] figure 1 The shown welding fume purifier includes several fume hoods 1, each fume hood 1 is connected to an exhaust device 3 through a gas delivery pipe 2, and a flame-retardant filter layer 4 is arranged inside the fume hood 1, and the exhaust device 3 is sequentially Coarse dust filter layer 5, suction pump 6 are provided, and suction pump 6 is provided with muffler 7, and described suction device 3 is connected to purification pool through connecting pipe 8, and purification pool comprises static pressure settling chamber 9, negative ion successively. Purification chamber 10, activated carbon deodorization chamber 11, an exhaust pipe 12 is provided at the upper end of the activated carbon deodorization chamber 11, one end of the static pressure settling chamber 9 is connected to a water inlet pipe 13, and one end of the activated carbon deodorization chamber 11 is connected to an outlet pipe 15 and an inlet pipe 13 A circulation pipe 14 is connected with the water ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com