Off-gas treatment system and method

A tail gas treatment and tail gas technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve problems such as large investment and thermal pollution, and achieve the effect of saving initial investment and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

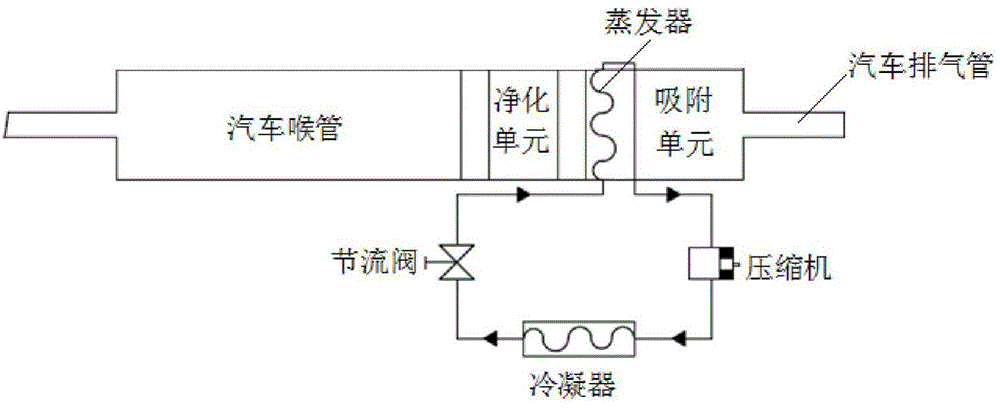

[0024] Such as figure 1 The exhaust gas treatment system shown mainly includes an adsorption unit, a cooling subsystem and a purification unit arranged sequentially along the exhaust gas discharge direction, wherein the adsorption unit and the purification unit are mainly used for adsorption purification treatment of automobile exhaust in different stages , to reduce the chemical pollution produced by it, and the cooling subsystem is used to cool down the exhaust gas and reduce the thermal pollution produced by it; among them:

[0025] The main effective structure of the purification unit is a filter with activated carbon fiber and zeolite, and the cooling subsystem is a closed loop composed of an evaporator, a condenser, a compressor and a throttle valve, which are placed between the purification unit and the adsorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com