Nonferrous metal ore flotation collecting agent with mercapto-oximido structure and application thereof

A technology for non-ferrous metals and collectors, applied in flotation, solid separation and other directions, can solve the problems of waste of resources, inability to effectively capture sulfide minerals or oxidized minerals at the same time, and difficulty in recycling, so as to increase the recovery rate and meet industrial applications. Requirements, the effect of simple recycling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of N,N-dibutyldithiocarbamate acetone oxime:

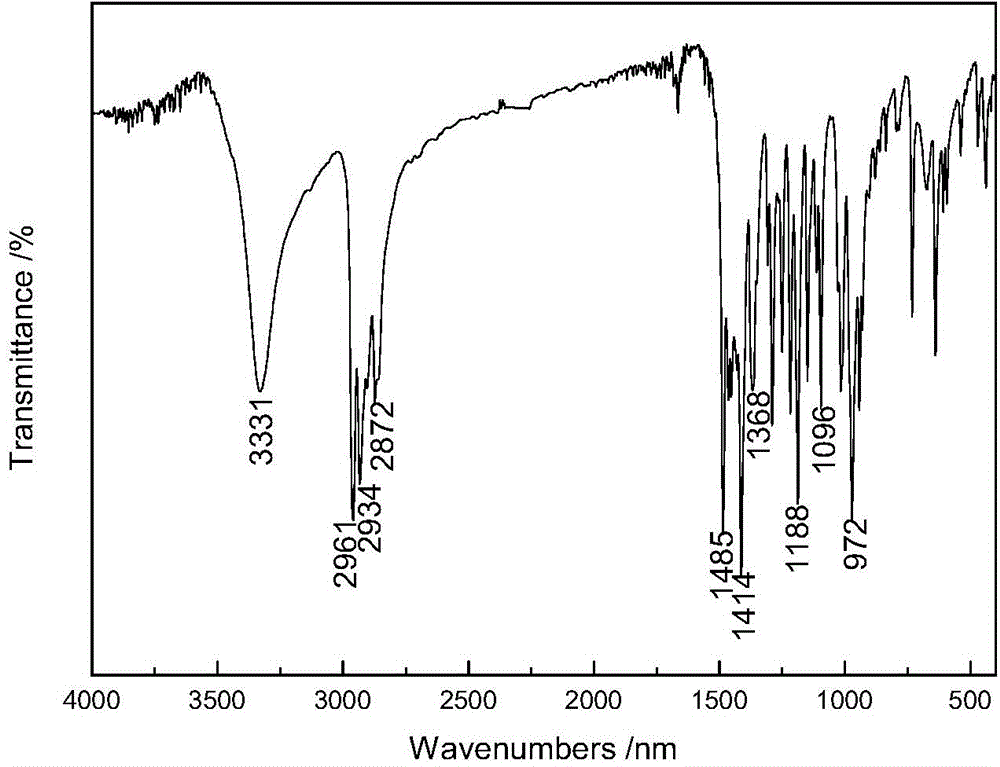

[0037] Add 15.63 parts of sodium N,N-dibutyldithiocarbamate to a mixed solution of 6.72 parts of chloroacetone oxime and 36 parts of methanol at a temperature of 20°C under stirring, and then stir and react at 20°C for 2 hours. After filtration, the filtrate was distilled under reduced pressure and washed with water to obtain a white solid, which was N,N-dibutyldithiocarbamate acetone oxime. The yield was 95%. Product infrared characterization such as figure 1 shown.

Embodiment 2

[0039] Preparation of N,N-dibutyldithiocarbamate acetaldoxime:

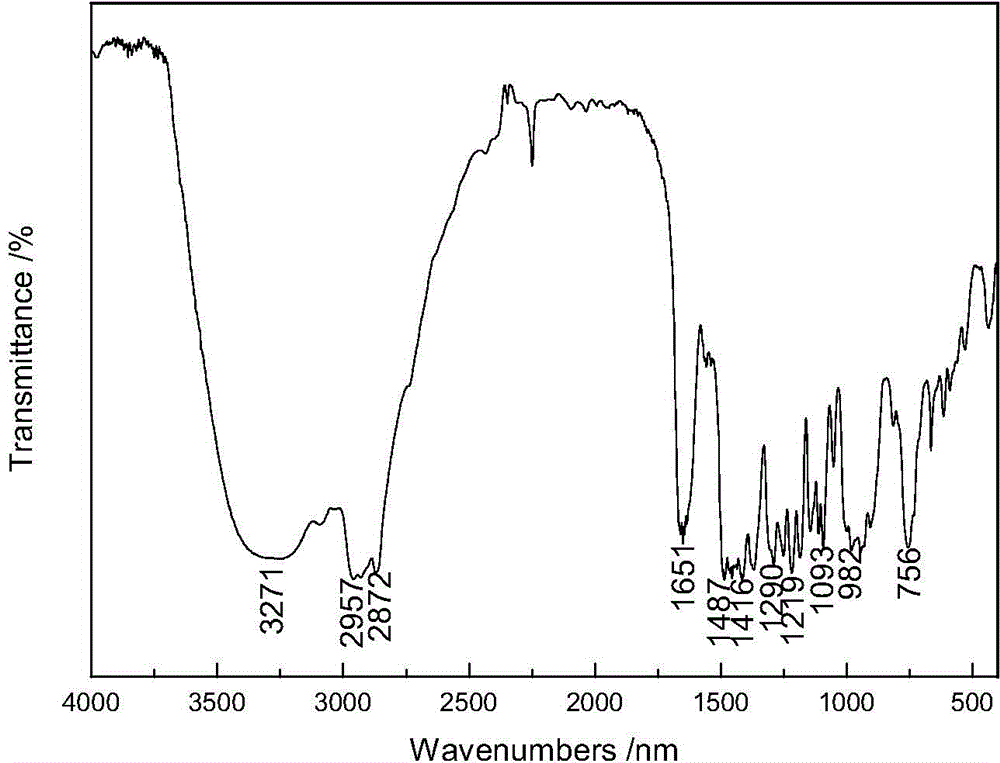

[0040] Add 15.63 parts of sodium N,N-dibutyldithiocarbamate to a mixed solution of 4.68 parts of chloroacetaldoxime and 36 parts of methanol at 20°C under stirring, and then stir and react at 20°C for 2 hours. After filtering, the filtrate was distilled under reduced pressure and then washed and dried to obtain a dark red oily liquid, namely N,N-dibutyldithiocarbamate acetaldoxime. The yield was 96%. Product infrared characterization such as figure 2 shown.

Embodiment 3

[0042] Preparation of O-isobutyl xanthate acetone oxime

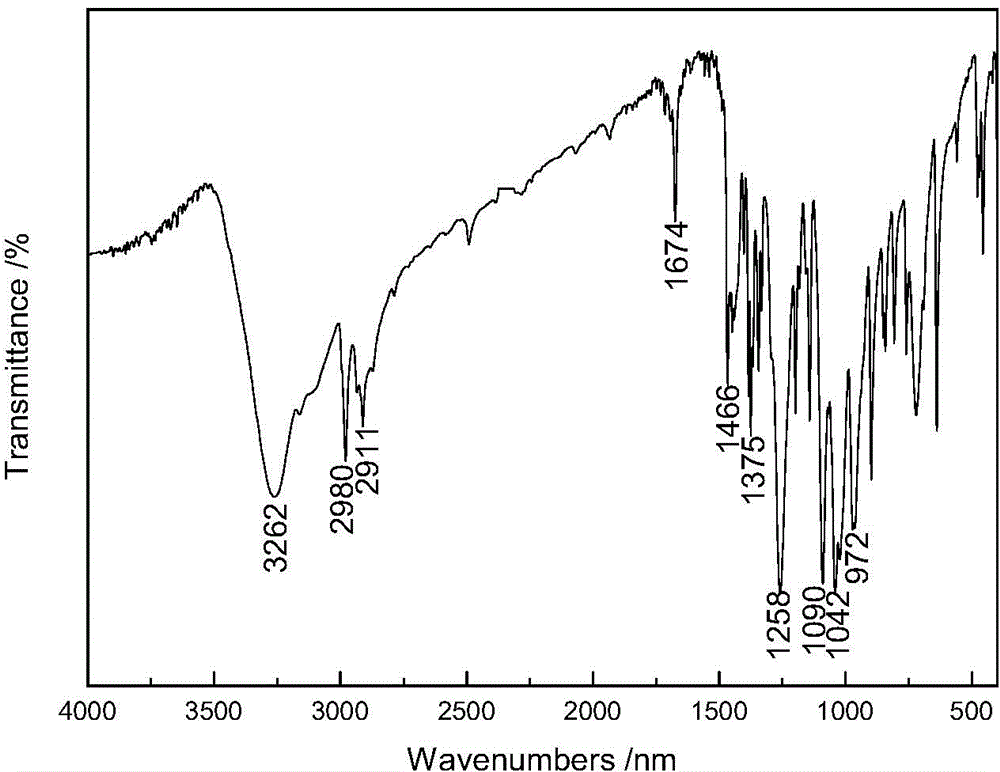

[0043] Add 17.2 parts of sodium isobutyl xanthate to a mixed solution of 10.75 parts of chloroacetone oxime and 36 parts of methanol at a temperature of 20°C under stirring, and then stir and react at 20°C for 2 hours. After filtering, the filtrate was distilled under reduced pressure and washed with water to obtain a white solid, which was O-isobutyl xanthate acetone oxime. The yield was 90%. Product infrared characterization such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com