Double-layer cyclone separator rotating parallel dust removal device

A technology of cyclone separator and dust removal device, which is applied in the direction of cyclone device, device whose axial direction of cyclone can be reversed, etc., can solve the problems of uneven distribution of air volume and low dust removal efficiency, and achieve uniform separation efficiency and uniform air volume. , the effect of efficient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

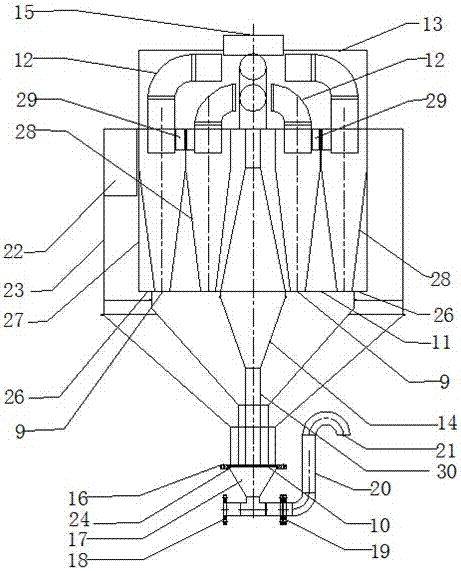

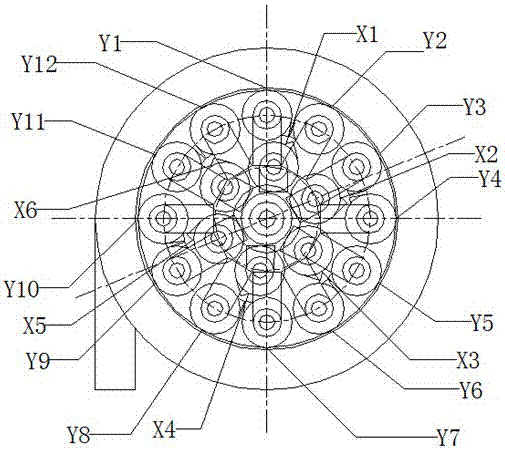

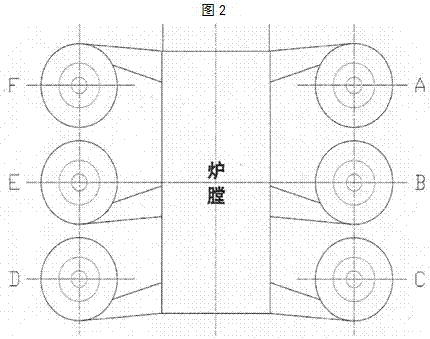

[0021] Embodiment 1, with reference to figure 1 , 2 , a double-layer cyclone separator rotating parallel dust removal device, mainly composed of a central cylinder 14, a middle cylinder 27, and an outer cylinder 23 arranged coaxially, with cavities between them, and sealed and isolated from each other. The lower part of the cylinder is a cone structure, and the cone ends of the middle cylinder 27 and the outer cylinder 23 are inner and outer bottom outlets 10, 24, and the inner and outer bottom outlets 10, 24 pass through the flange and the ash discharge device 6 connection; the upper end of the cavity between the intermediate cylinder 27 and the outer cylinder 23 is provided with a tangential inlet 22; several small cyclone separators 28 are distributed in the cavity of the intermediate cylinder 27 in double layers, and the outer layer Several cyclone separators in the three cylinders are evenly fixed on the inner wall of the middle cylinder 27 with the center of the three ...

Embodiment 2

[0024] Embodiment 2, with reference to figure 1 The bottom trough 17 of the ash discharge device communicates with the central cylinder 14 through the sewage pipe 30 to solve the problem of dust accumulation in the central cylinder 14 . The rest are the same as embodiment 1.

[0025] The working process of the present invention: the dust-laden air flow enters the upper end of the cavity between the outer cylinder body 23 and the middle cylinder body 27 tangentially from the tangential inlet 22 to generate a swirling flow, and perform first-stage separation under the action of centrifugal force. The separated coarse particles or liquid droplets will fall to the inner wall of the cone at the lower end of the outer cylinder 23 and be discharged through the outlet 24 of the outer bottom. The airflow through the first stage of separation enters the bottom of the intermediate cylinder 27 through the air inlet ring hole 26, and then rotates into each cyclone separator 28 from the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com