Automobile shock absorber connecting rod and locating sleeve welding and detection all-in-one machine

A technology of automobile shock absorbers and positioning sleeves, which is applied to welding equipment, using stable tension/pressure to test the strength of materials, vehicle components, etc., which can solve the problems of not being suitable for modern production, large equipment footprint, and low production efficiency. problems, to achieve significant economic benefits, reduce personnel, and ensure the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

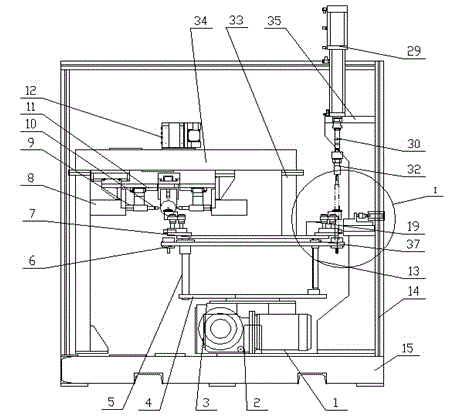

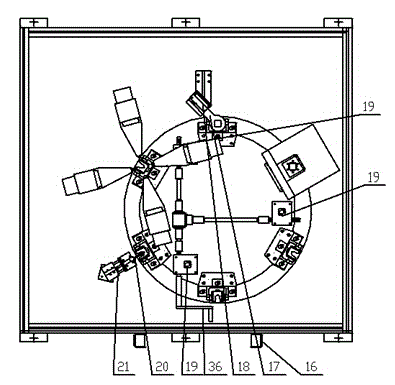

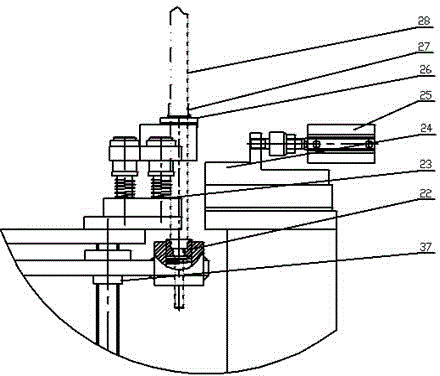

[0020] The present invention is a six-station turntable structure, which are respectively an upper and lower workpiece station, a workpiece inspection station, a welding station, a degaussing station, a strength inspection station, and a waste product unloading station. Its components include a frame 33 , a base 15 , a motor 1 , a reducer 2 , a cam splitter 3 , a rotary table, a workpiece detection mechanism, a welding mechanism, a degaussing mechanism, a strength detection mechanism, and an aluminum alloy shield 14 .

[0021] figure 1 , 2 It shows that the rotary table is installed on the base 15, the motor 1 is connected with the cam divider 3 through the reducer 2, the cam divider 3 is connected with the rotary table, and the motor 1 and the reducer 2 drive the cam divider 3 to realize the rotary operation The six-position indexing rotation of the table. The workpiece detection mechanism, welding mechanism, degaussing mechanism, and strength detection mechanism are instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com