A Symmetrical Concentrated Force and Uniform Load Coupled Hot Bending Forming Device and Its Application

A technology of uniform load distribution and concentrated force, applied in the field of solar energy, can solve the problems of reducing the specular reflection ability of solar radiation in high-energy bands, cost constraints on solar heat utilization, and surface distortion, etc., to achieve strong elastic self-restraint ability, small stress deformation, The effect of preventing temperature unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1 is used to prepare a hot-bending forming device for a condenser.

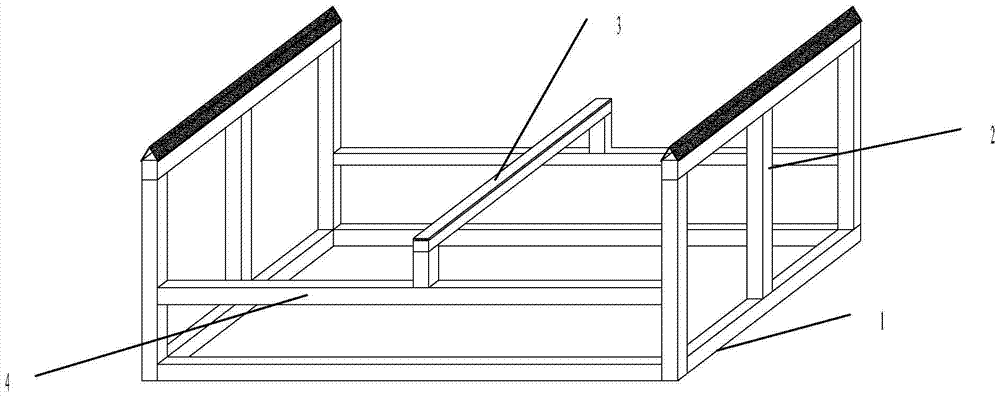

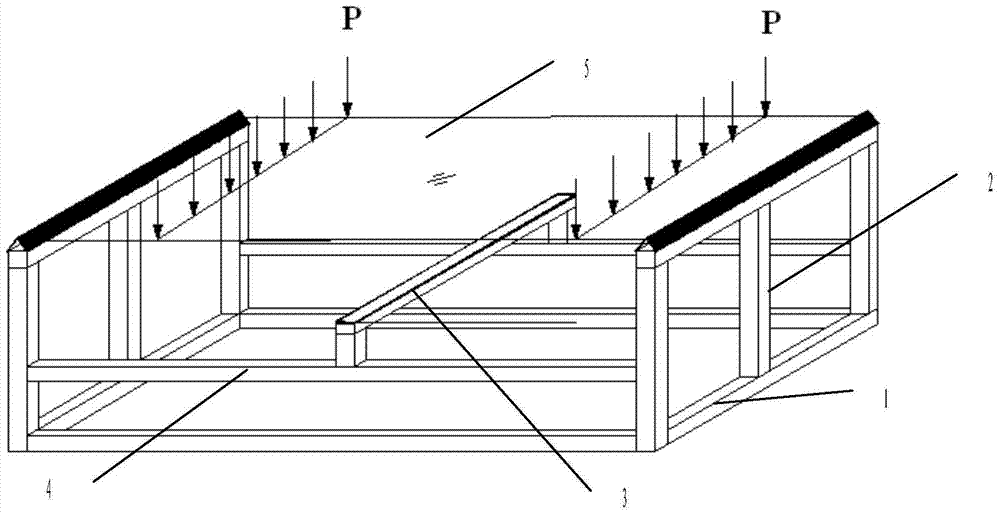

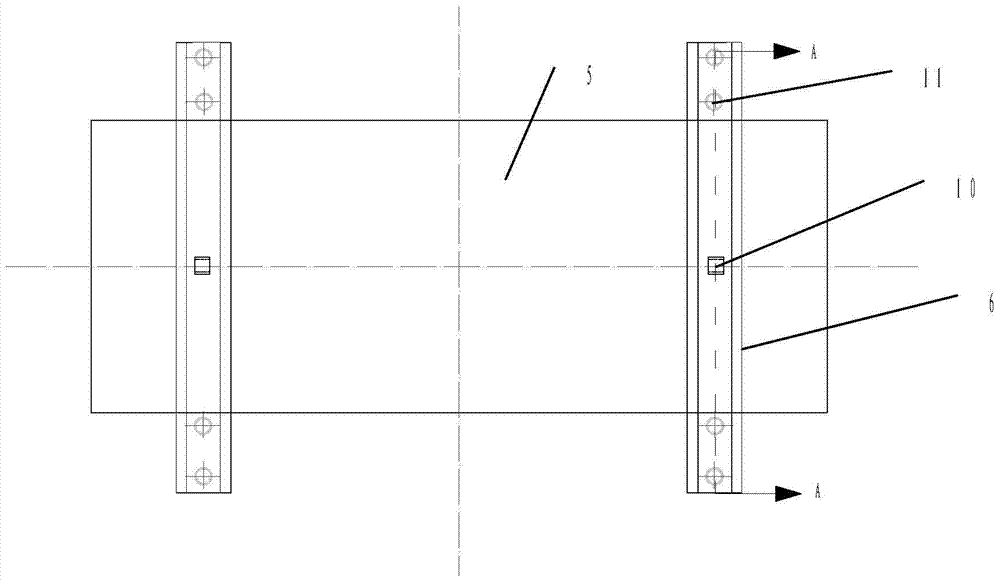

[0053] The invention provides a hot bending forming device for preparing a condenser lens, such as figure 1 As shown, it includes a mold frame and a concentrated force loading unit, wherein the mold frame is a hollow structure as a whole, including a base 1, a support frame 2 and a limit beam 3, wherein the support frame 2 is arranged at both ends of the base and is perpendicular to the base , the two support frames are fixedly connected by a support beam 4, and a limit beam 3 is erected between the two support beams 4, and the limit beam 3 is used to control the crown height of the prepared condenser. The mold frame is welded by square steel or angle steel. The support surface at the top of the support frame forms an included angle with the glass plate to be processed in the range of 30-60°C. The support surface at the top of the support frame is covered with a layer of high-temperature resis...

Embodiment 2

[0055] Example 2 A condenser lens is prepared under the coupled action of symmetrical concentrated force and uniformly distributed load.

[0056] The present invention utilizes the coupling effect of symmetrical concentrated force and uniformly distributed load to prepare the concentrator, and the manufacturing method steps are glass type selection—glass entering the furnace—installation of the concentrated force application unit—position control through the limit beam of the mold frame, and the bending temperature Control, annealing with the furnace to complete the hot bending forming process - glass surface shape verification - edge trimming - coating, etc.

[0057] Specific steps are as follows:

[0058] (1) According to the requirements of the hot-bending condenser, select a low-iron soda-lime glass plate with a thickness of 4mm, an error of ±0.2mm, a span of 1500mm, and an error of ±2mm. In terms of the geometric dimensions of the glass condenser, a glass original sheet ...

Embodiment 3

[0066] Example 3 Condenser performance test.

[0067] (1) Roughness test

[0068] Statistical analysis of the roughness Ra values of 10 condenser lenses before and after hot bending obtained by hot bending under the action of pure uniform load of the same hollow mold in the early stage by using the high-precision roughness tester Mahr Perthometer M1 (with PFM drive unit) made in Germany . The results show that the average value of glass roughness before bending is 10.7nm, and the total average value after bending is reduced to 10nm, which shows that the condenser lens has excellent surface properties.

[0069] (2) Symmetrical concentrated force and uniform load coupled thermoformed condenser lens concentrating effect

[0070] Concentration analysis was carried out for a loading scheme with b = 0.15m. Firstly, the solid modeling of the solar concentrator is carried out through SolidWorks, and then the solid model is imported into Tracepro optical software for optical traci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com