Non-contact automatic tool setting module and non-contact automatic tool setting method for internal thread groove of nut

A nut internal thread and automatic tool setting technology, which is applied in metal processing equipment, grinding workpiece supports, manufacturing tools, etc., can solve the difficulty of automatic tool setting method and device with high precision and high efficiency, and nut automatic tool setting , can not be directly applied and other problems, to achieve good market prospects and development potential, accurate and reliable tool displacement data, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

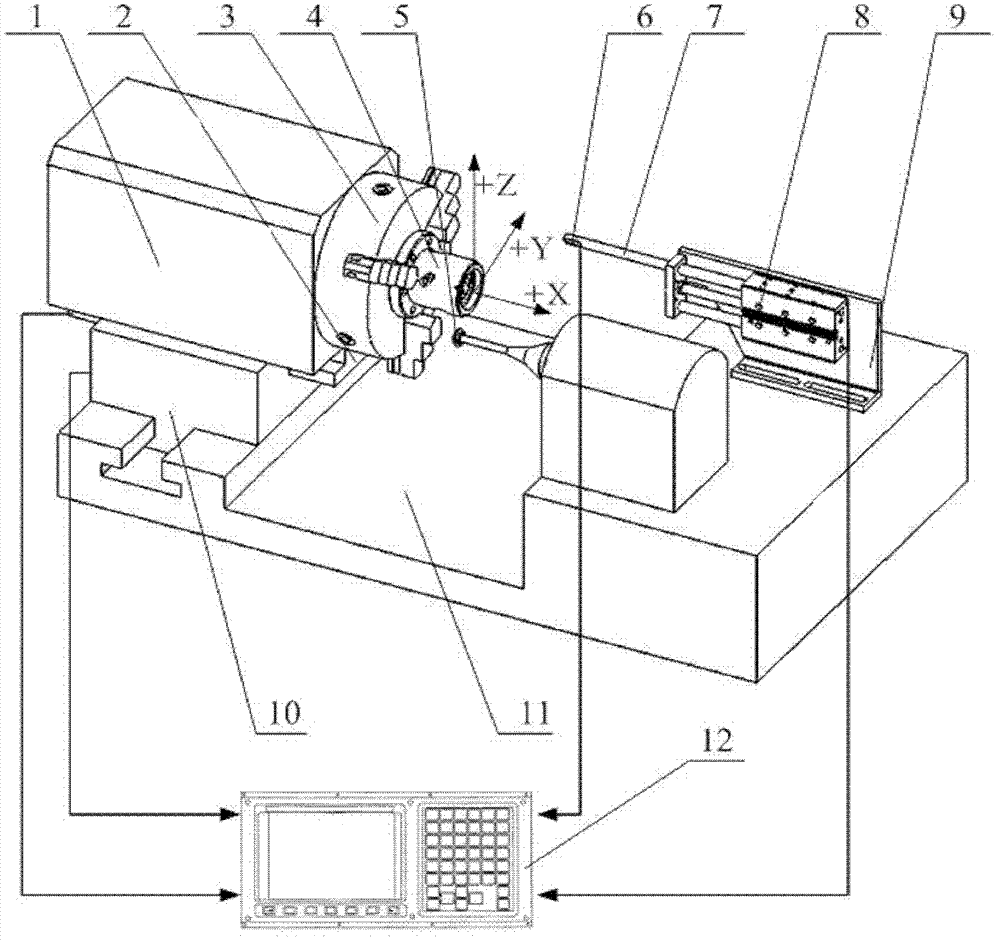

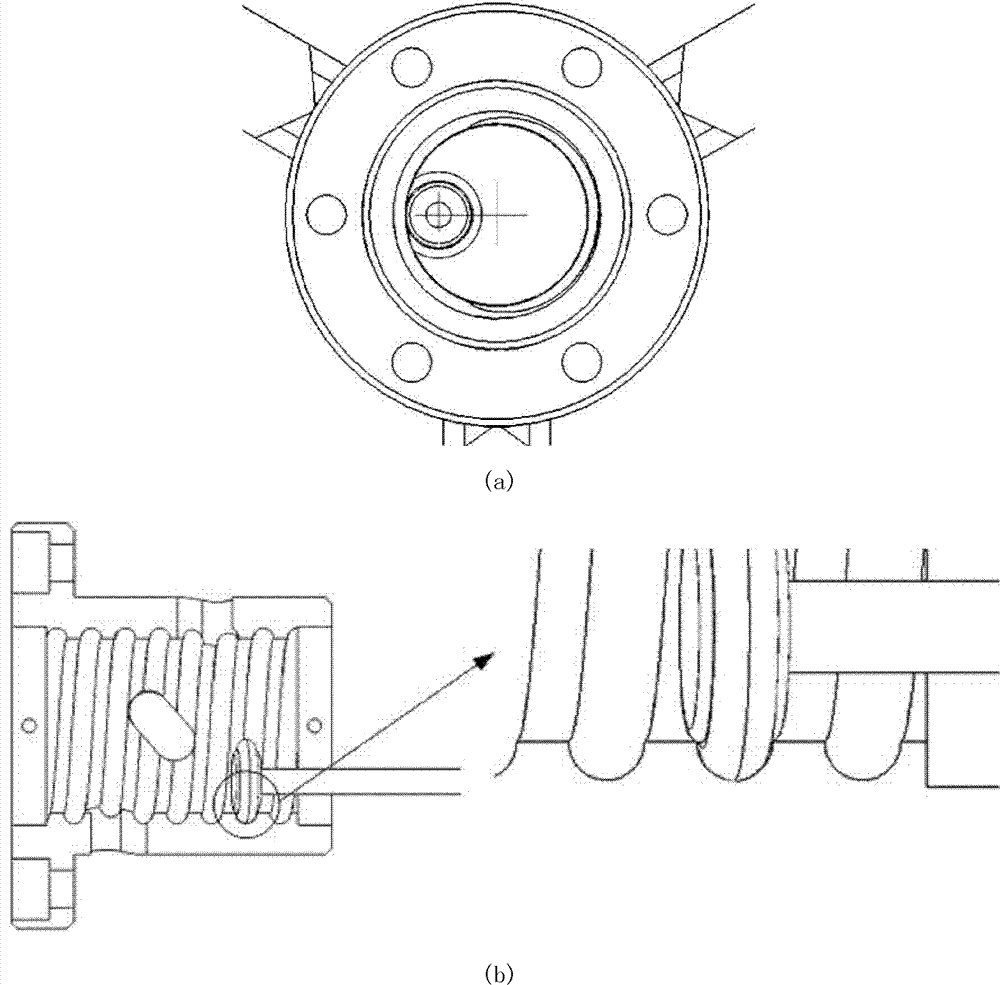

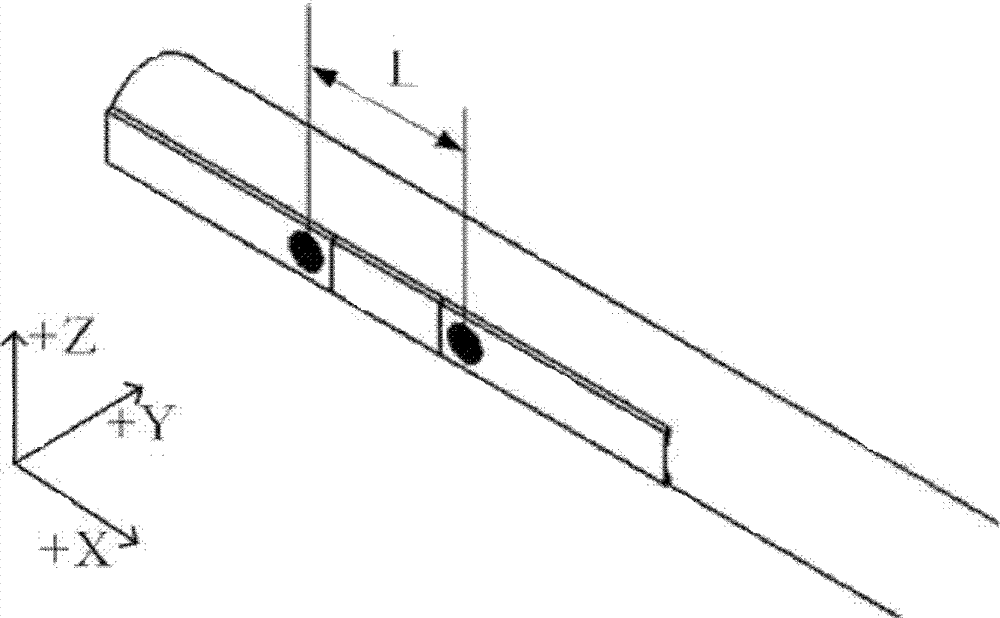

[0017] The invention adopts the cooperation of the proximity switch and the numerical control system to collect data on the axial displacement of the level change point of the internal thread raceway of the nut to be measured, wherein the proximity switch can realize the telescopic movement of the axial displacement along with the cylinder; the nut can be positioned along with the lateral translation The mechanism and the axial translation positioning mechanism can realize the position adjustment in the horizontal plane. By performing corresponding coordinate transformation processing on the collected displacement data, the grinding starting position of the grinding wheel can be determined, thereby realizing the non-contact automatic tool setting of the inner thread raceway of the nut, and the tool setting efficiency and accuracy are high.

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com