A kind of high temperature resistant recyclable foam drilling fluid and preparation method thereof

A drilling fluid and high-temperature-resistant technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem that the drilling fluid cannot meet the high temperature environment above 200 ℃, and achieve strong inhibition and suspension ability, strong stability, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

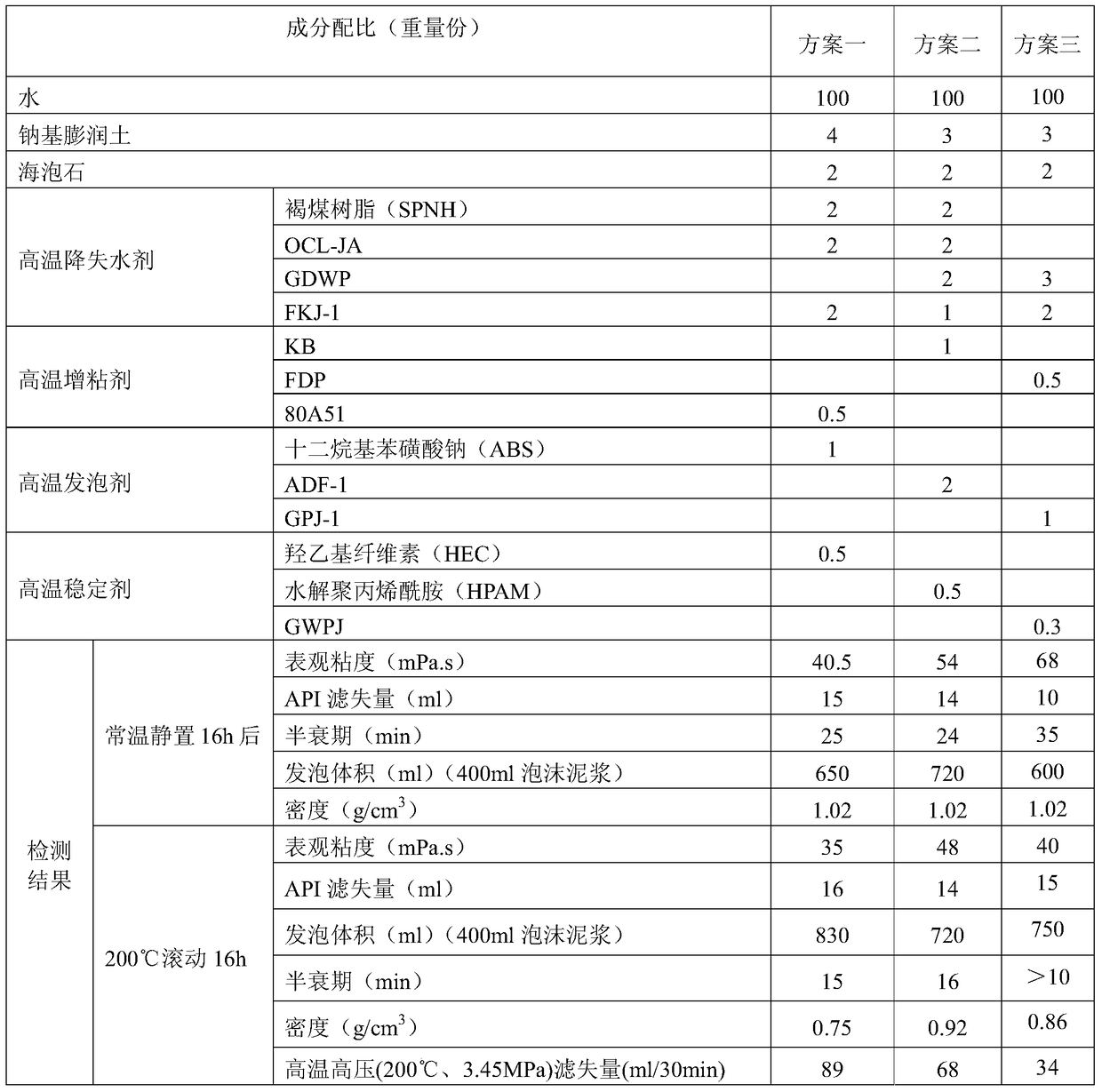

Examples

Embodiment 1

[0029] This embodiment provides a high temperature resistant recyclable foam drilling fluid, including the following components:

[0030] Sodium-based bentonite, any commercially available sodium-based bentonite can be selected, such as: sodium-based bentonite supplied by Shandong Weifang Tiantong Sodium Soil Co., Ltd., sodium-based bentonite supplied by Chifeng Shengchuan Bentonite Co., Ltd., artificial Sodium soil. Bentonite produced by Chifeng Shengchuan Bentonite Co., Ltd. is preferably used in the present invention.

[0031] For sepiolite, any commercially available sepiolite can be selected, such as: sepiolite supplied by Hebei Hongli Sepiolite Cashmere Co., Ltd., sepiolite supplied by Xingyuan Sepiolite Development Co., Ltd., Neixiang County, Henan Province , Sepiolite supplied by Hunan Tianjie Sepiolite Co., Ltd., etc. The sepiolite produced by Hunan Tianjie Sepiolite Co., Ltd. is preferably used in the present invention.

[0032] High temperature fluid loss reducer...

Embodiment 2

[0043] A high-temperature-resistant recyclable foam drilling fluid provided in this embodiment includes the following components in parts by weight: 100 parts of water, 2 parts of sodium bentonite, 1 part of sepiolite, 2 parts of high-temperature dehydration agent and 1 part of high-temperature foaming agent, does not contain high-temperature tackifier and compound high-temperature foam stabilizer.

Embodiment 3

[0045] A high-temperature-resistant recyclable foam drilling fluid provided in this embodiment includes the following components in parts by weight: 100 parts of water, 6 parts of sodium bentonite, 3 parts of sepiolite, 10 parts of high-temperature dehydration agent, 2 parts of high temperature tackifier, 3 parts of high temperature foaming agent and 2 parts of composite high temperature foam stabilizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com